Every day to open the courier, supermarket shelves of goods, factory parts on the assembly line ... ... looks like a commonplace behind the items are hiding a ”stealth porter” legion - automated conveyor equipment. They work tirelessly throughout the day, today we will recognize the 7 types of automated conveyor equipment to change the modern logistics!

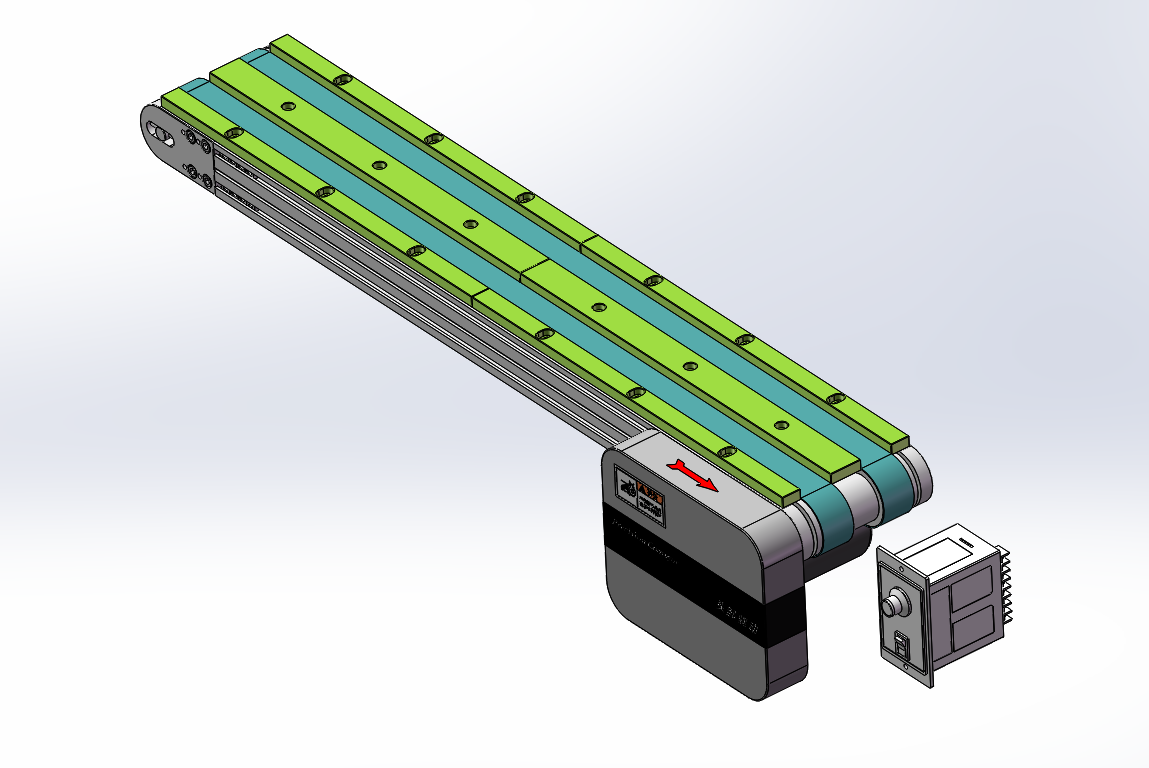

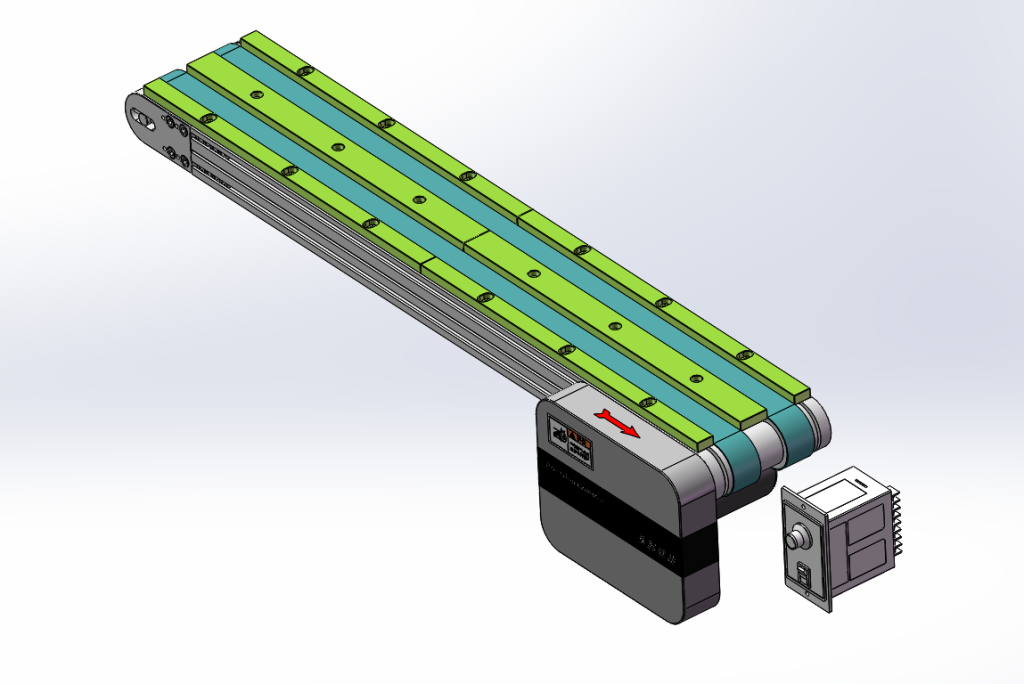

1. Belt conveyors

Working Principle:By means of a motor-driven rubber/metal belt that rotates in a circular motion, items are placed on the belt and transported smoothly.

Advantage:

✔ Zero vibration during transportation to protect fragile items

✔ Up to 500 meters across (equivalent to the length of 5 soccer fields)

✔ Lower energy consumption than trucking 80%

Usage Scenarios:3c electronics factories (conveying small parts), courier sorting centers (handling millions of packages per day), mines (transporting ores), airport baggage systems

2. Roller conveyors

How it works:Densely arranged metal rollers make up the conveyor surface and allow the items to roll forward by gravity or motor drive.

Advantage:

✔ Load capacity up to 2 tons (equivalent to the weight of a car)

✔ Flexibility to turn and form S-shaped routes

✔ Maintenance requires replacement of only a single drum

Usage Scenarios:Automobile manufacturing plants (door/engine delivery), warehouse logistics (pallet transportation), beverage filling lines

3. Chain plate conveyor

How it works:The metal chain plates are linked together to form a sturdy conveyor surface, which is particularly suitable for harsh conditions.

Advantage:

✔ Resistant to high temperature of 300℃ (essential for bread baking line)

✔ Not afraid of oil corrosion (preferred by automobile spraying workshop)

✔ Lifespan up to 10 years +

Usage Scenarios: Food baking lines, waste treatment plants, heavy machinery assembly lines

4. Screw conveyors

How it works:Like a giant screw, the material is ”rolled” from a low place to a high place by rotating the screw blades.

Advantage:

✔ Vertical lifting saves 80% floor space

✔ Fully enclosed with no dust leakage

✔ Simultaneous mixing + conveying possible

Usage Scenarios:Grain warehouses (wheat/corn elevation), cement plants, sewage treatment plants

5. AGV trolley

How it works:Driverless transportation vehicle with its own navigation system (laser/QR code) that automatically avoids obstacles and recharges.

Advantage:

✔ Paths can be adjusted by software at any time (best partner for flexible production)

✔ Less than 5mm error (10 times more accurate than human operation)

✔ 7 x 24 hours uninterrupted operation

Usage Scenarios:Intelligent Warehousing (Jingdong Asia No. 1 Warehouse), Medical Material Distribution, Semiconductor Cleanroom

6. Suspension conveyors

How it works:Items are transported suspended on an overhead track, making perfect use of three-dimensional space.

Advantage:

✔ No floor space is occupied (workshop aisles are used as usual)

✔ Multi-layer transportation networks can be designed

✔ Self-drying function (commonly used in automotive painting lines)

Usage Scenarios:Clothing dry-cleaning chain, automobile spraying line, slaughtering and processing plant

7. Pneumatic conveying system

How it works:Compressed air is used to form an airflow in the pipe, which pushes the powdered material to move at a high speed.

Advantage:

✔ Speed up to 25m/s (3 times faster than a running champion)

✔ Enclosed transportation to eliminate contamination

Usage Scenarios:Flour mills, pharmaceutical plants (raw material conveying), thermal power plants (pulverized coal conveying)

How to chooseThe most suitable conveying equipment?

Remember this golden formula:

Material Characteristics(weight/form) + environmental requirements (temperature/cleanliness) + space conditions = most suitable type of equipment

The next time you receive a courier, imagine: this package may have experienced belt machine sorting, screw machine lifting, AGV cart handling ... finally came to your front. It is these silent work of the ”steel partners”, so that modern logistics has become so efficient!