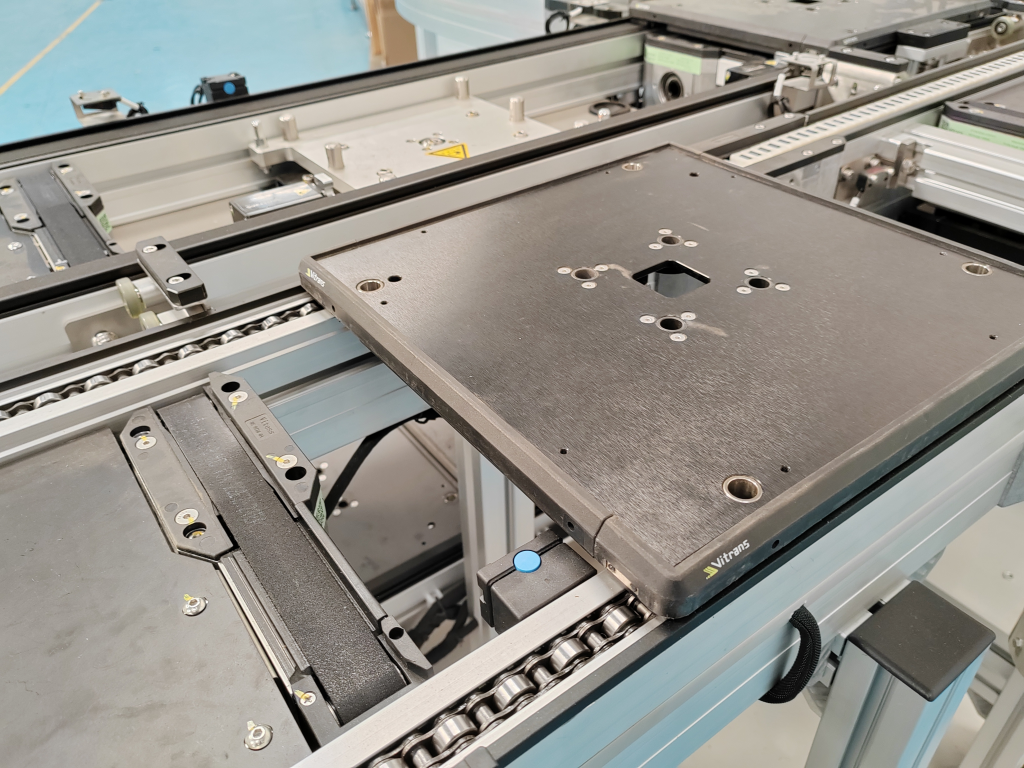

doubled speed chainThe role of the conveyor line in the production line:With the most efficient path, the fastest speed, accurately conveying materials from one position to another in the production site, complete the transfer of production materials, to ensure that the production of various products in accordance with the needs of coordinated and according to the needs of rapid change.

01Multiple speed chain line 7Big Core Advantages:

- High conveying capacity for large load weights

- Accurate and stable conveying speeds ensure precise synchronized conveying

- Easy to realize accumulation conveying, can be used as an assembly line or as a material storage and conveying.

- Can work in various harsh environments (high temperature, dust), reliable performance

- Made of special aluminum profiles for easy installation

- Modular design, beautiful structure, practical low noise

- Multi-functional integration and high degree of automation are possible

02Industry Application Scenarios

Widely used in home appliances, machines, logistics, food and other industries. For example, computer monitor production line, computer mainframe production line, laptop assembly line, air conditioner production line, TV assembly line, microwave oven assembly line, printer assembly line, fax machine assembly line, audio amplifier production line, engine assembly line and so on.

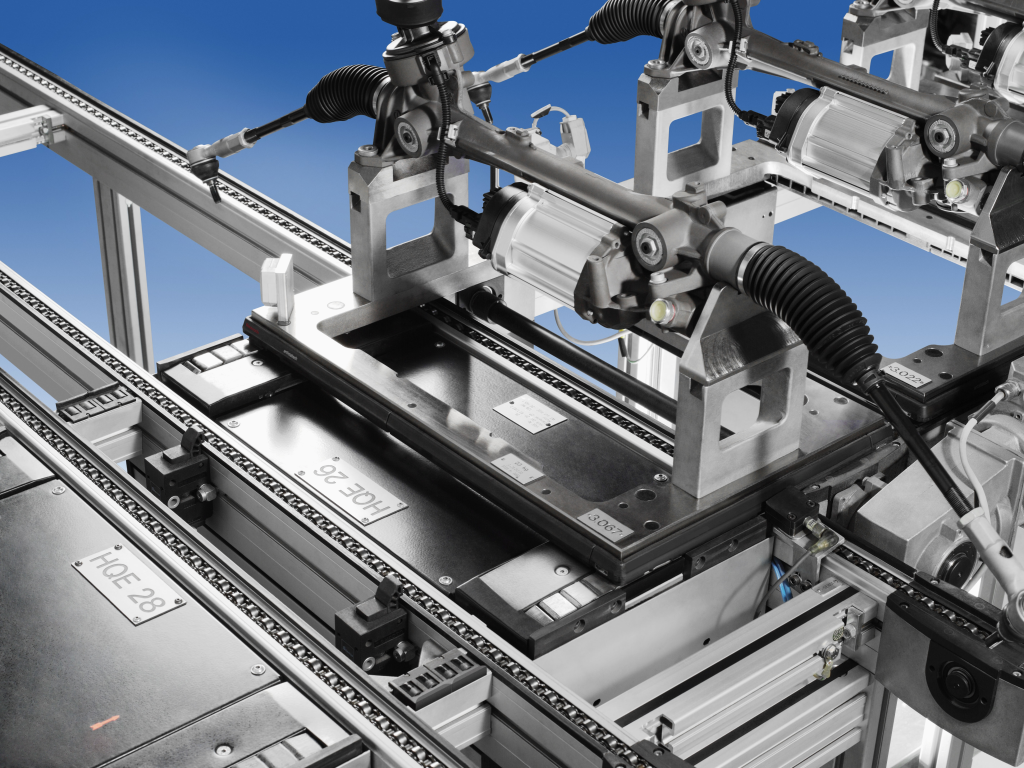

▶ Automotive Manufacturing: Engine assembly line with 4000kg heavy-duty version of cylinder block conveyed with jacking positioning unit for millimeter precision assembly

▶ 3C Electronics: In the notebook production line, the S-shaped space layout is realized by the 90°turn unit, saving 30% factory floor space.

▶ New Energy: When battery packs are transported, RFID smart trays automatically identify the model, and there is no confusion in the mixed line production of different cells.

▶ Home appliance field: Air conditioner outboard assembly line utilizes stacking function to automatically form a cache queue before the coating process

03Selection and avoidance of pitfallsguidebook

• Look at the load:Below 60kg, use synchronous belt, within 250kg, use flat belt, over 1000kg, use speed chain.

• Look at the environment:Steel chain for high temperature workshop, anti-static nylon model for clean room.

• Look at the layout:Matching CV/90 turning units when turning is required, and LP/S screw jacks for multi-story plants.

• Look for extensions:Reserve jacking traverse station, convenient for future increase in the inspection process

04Customer's real case

An automotive parts plant after remodeling:

-Replacement of conventional chain with speed chain + WE2 pallet (240 kg load).platen line

-U-shape layout through 180° turning unit saves 40% space

-25% capacity increase due to accumulation function, reducing changeover time from 4 hours to 30 minutes.

Find out now and getProduction Line LayoutDesign program. Our engineers can also customize different versions for you: dustproof/high-temperature-proof, etc., as well as robotic automatic loading and unloading integration services, so that your production line all the way smooth.