In industrial production, the conveyor is the key to open the flow of materials. Want to use it well, we have to first distinguish the characteristics of different models, and then only to match their own needs to choose the most suitable for their own use. The following for you to dismantle the 6 types of common conveyor, to help you quickly choose the right conveying equipment:

1. belt conveyor

Belt conveyor, it mainly rely on belts, tapes and other conveyor belts to transport goods. It can be designed as horizontal, climbing, turning, but pay attention to the best climbing angle is not more than 18 °, if it must be more than that, add transverse baffle, can prevent the goods from slipping.

Core strengths:

- Save your heart: simple structure, low failure rate, low energy consumption, loading and unloading andmaterial handlingIt's all very convenient.

- High conveying efficiency: large conveying capacity and long conveying distance, from a few meters to 10 kilometers can be conveyed.

- Wide range of applications: can be used for small pieces, bulk materials (such as grain, gravel) conveying, but also can be used in the assembly line of the electronic factory

Applicable Scenarios:It can be used in courier sorting centers, electronic assembly plants, grain/coal and other bulk material transportation, especially in scenarios that require horizontal or inclined conveying.

2. Roller Conveyor

Roller ConveyorIt is relying on multiple sets of rollers to convey materials, the main structure consists of rollers, motors, body track, according to the drive mode, one is powered, driven by motor; one is powerless, relying on the weight of the material itself to slide. Roller conveyor can also do horizontal, small angle slope or turn type, but pay attention to the inclination angle can not be too big.

Core strengths:

- Strong load capacity: can transport cargo boxes, pallets, and single piece of large weight materials, more can withstand the impact of heavy loads.

- Flexible layout: multipleplaten lineComplex conveyor systems can also be formed if they are put together in an orderly fashion.

- Simple maintenance: rollers can be replaced, a single broken roller does not affect the overall use, maintenance is also convenient

Fits the scene:It can be used to transport boxed goods in the beverage, food, and pharmaceutical industries, as well as palletized materials in the 3c electronics and automotive parts industries. However, it should be noted that the roller line cannot directly transport bulk materials, small or irregular items, such as unpacked parts and so on.

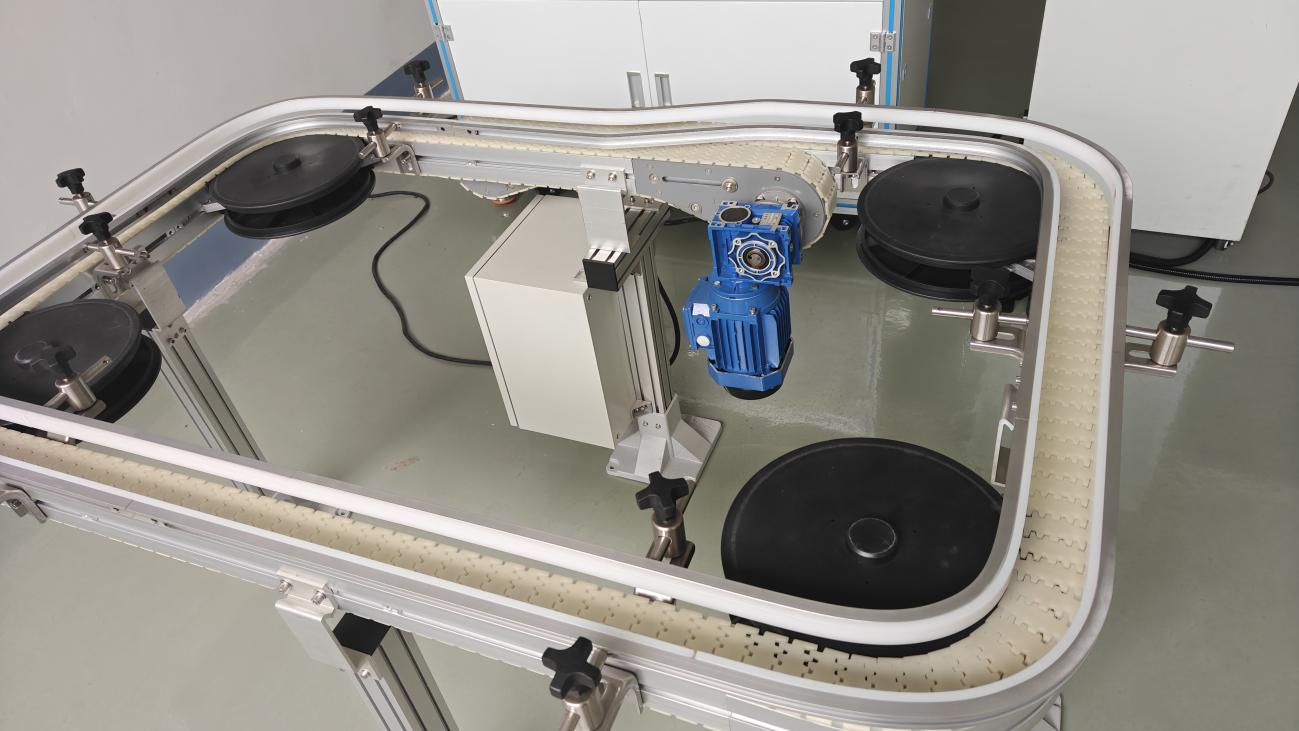

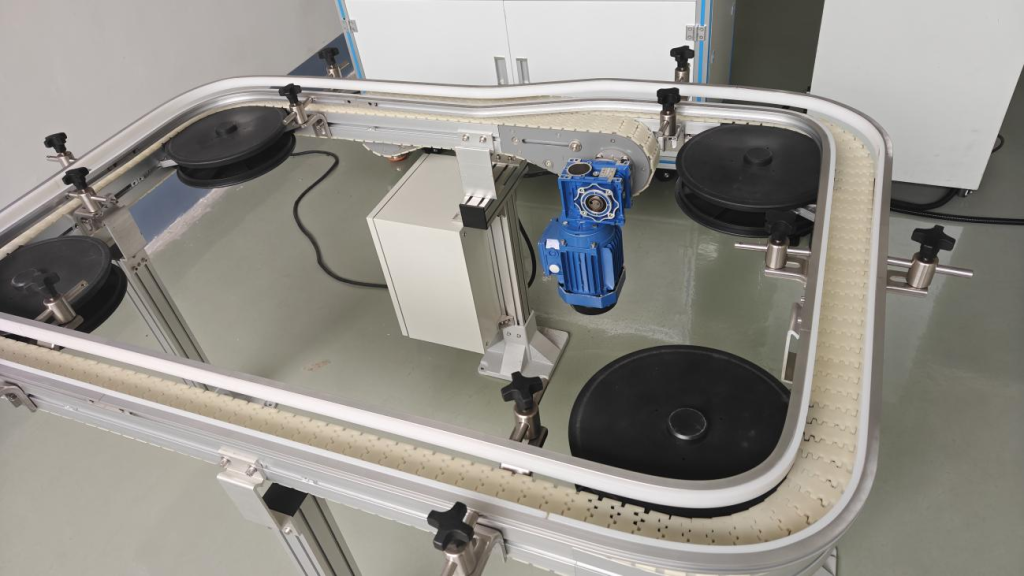

3. Chain plate conveyor

The principle of chain conveyor is to rely on the cycle of chain to traction operation, chain plate as a carrier to put the material, mainly stainless steel, engineering plastics two categories of materials, generally can be directly rinsed with water, cleanliness is relatively high.

Core strengths:

- Smooth conveying: the conveying surface of the chain plate line is smooth, the material transition is very smooth, conveying glass bottles, cans, bags can be...

- carrying capacityStrong: Stainless steel chain plate line is very capable of bearing weight, conveying such as automobile parts, generator parts, large home appliances and other products, conveying up to be very stable.

- High hygiene standards: because most of the material can be washed directly with water, it is easy to clean, especially in line with the food and beverage industry's requirements for hygiene

Fits the scene:Bottles and cans are conveyed in food and beverage factories, small products are conveyed in daily chemicals and cosmetics, as well as automotive parts and components for heavy-duty conveying, and most scenarios that require frequent cleaning.

4. Screw conveyors

This kind of conveyor mainly relies on the internal spiral blade rotation to promote the material, can be divided into two forms of horizontal and vertical, as well as curved, spiral tube type, its biggest feature long is the cross-section is relatively small, and can realize the sealing of the material conveyor.

Core strengths:

- Save space: generally use the three-dimensional form of conveying, do not need to occupy too much space, but also in the middle of a number of positions to realize the loading and unloading of materials

- Good sealing effect: closed conveying mode, can well prevent dust leakage out, more suitable for the environment will produce pollution of materials.

- Low input cost: the structure is relatively simple, the cost will be cheaper than many conveyors, and easy to operate.

Fits the scene:

It is especially used in the building materials industry to transport cement, sand and gravel, and in the chemical and agricultural industries to transport powders and granules, especially when it needs to be sealed or vertically conveyed, and it is very suitable to choose it.

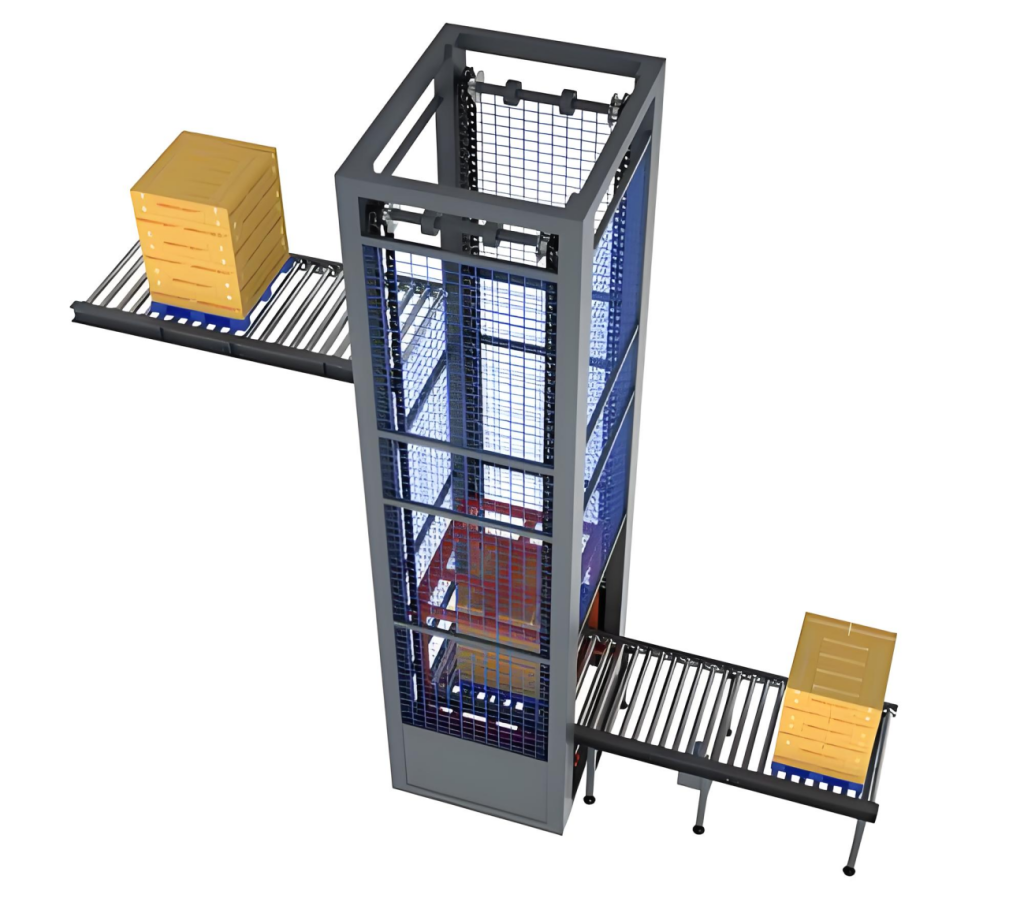

5. Vertical conveyors

Vertical ConveyorThe abbreviation is our elevator, generally on two types of continuous and reciprocating. Its core role is to be used to transport materials up and down, can be connected to different heights or floors of the conveyor, without the need for manual handling of materials can be done across the level of conveyor.

Core strengths:

- Space-saving: the hoist has a relatively small footprint, making it easy to have different layouts in the workshop

- Energy-saving and quiet: less power consumption, less wear and tear in the conveying process, and very low noise during operation.

- Realization of bi-directional conveying: it is possible to achieve bi-directional conveying of the upper and lower floors, with a high degree of flexibility.

Fits the scene:The need for multi-level transfer of materials in the industry, such as machinery, medicine, logistics and other industries, as long as you want to connect the different floors of the conveyor line to transport materials, this elevator is indispensable.

6. Overhead conveyors

Suspension conveyors are often used in aerial work, usually relying on chains and spreaders on the track to transport materials. Its special feature is that it can be used in a wide range of applications as it can be freely designed for routes across floors, plants and even parks.

Core strengths:

- Conveying span: long conveying distance, a line can solve the problem of conveying materials across the district

- Wear-resistant and durable: simple but sturdy construction, can be used in harsh environments such as high temperatures and dusty environments in spray booths

- Affordable cost: in terms of construction cost, energy consumption and maintenance costs are not high, with economic use of affordable

Fits the scene:It is often used for transporting fabrics in garment factories, transporting workpieces in spraying workshops, and production and assembly lines for automotive parts to achieve long-distance feeding.

In fact, the selection of conveyor, the main thing is to understand the characteristics of the conveyor material, as well as different factories to correspond to the production of different conveying needs, and then compared to the above characteristics of the model, you will be able to quickly find the right conveying equipment for themselves.