In such a hot day, manual assembly in the workshop must be very hard. It's time to use Wei Chuang's pallet conveyor system.

01 flatbelt conveyor

Flat Belt Conveyor Line,Also often referred to asSheet Base Belt Conveyor Line. Mainly made of nylon, the belt has high abrasion resistance and can withstand large friction and abrasion, making it ideal for long-term contact with pallets. Unlike ordinary belts, it also has anti-static function and strong anti-stretching, which can stabilize the conveyance at high speed. With work pallets, it can be used for automated transportation and sorting lines, and can be found in automotive electronics, logistics, warehousing, manufacturing and other fields.

02 Synchronous belt conveyor line

We are always asked if our belt lines are wear-resistant, just look at the conveying effect.

this oneSynchronous belt conveyor lineIt is optimized and designed by our team in two years, the load can be 60kg, the key is that it is particularly wear-resistant. In the laboratory for a long time for durability testing, and is 24 hours full load operation, up to now has been more than 3 years, the line body quality and stability has not changed, the service life than the life of similar products on the market 2 times more. This synchronous belt line also supports forward and reverse bidirectional operation, maintenance is also very simple. Other people's belts with less than a year to change, ours can be used continuously for three years without worrying, directly save a large amount of maintenance fees.

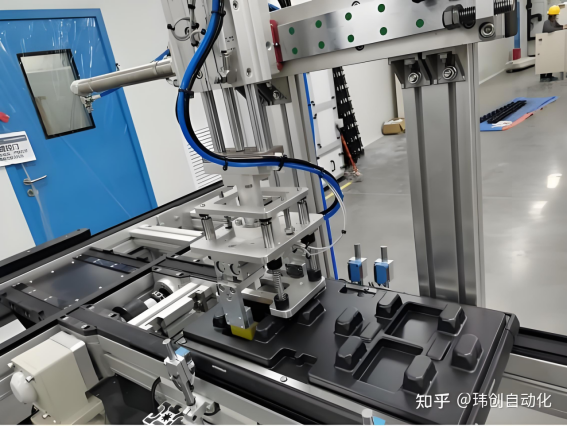

03doubled speed chainconveying line

Look again at this customizedSpeed Chain Conveyor Line. This speed doubling chain line adopts steel chain transmission, with stronger load bearing capacity, load 2200 kilograms easily. Chain tensioning device is also installed to adjust the chain tension at any time, so that the line can run more stable and solve the problem of chain durability that customers are worried about. It is very suitable for new energy batteries, automobile parts and other industries with heavy-duty conveying needs.

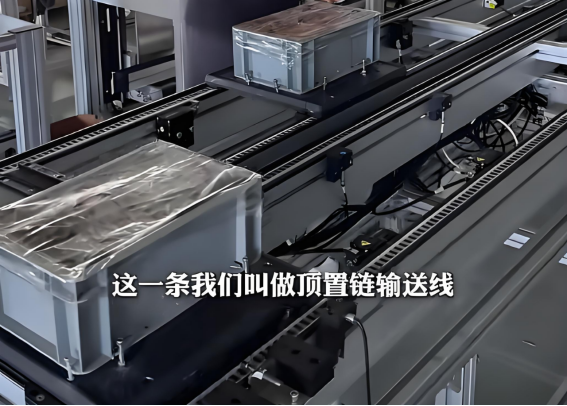

04 Overhead Chain Conveyor Line

Factory space is small, how to arrange the production line to save space and money?

Use ourOverhead Chain Conveyor LineIt can be used. First of all, its structure is compact, can build double or even multi-layer line body, to the high to space, does not take up the factory area, the factory is even small can also be used to open. And it also has the advantage of a high degree of cleanliness, chain wear-resistant and clean, can reach 10,000 clean standards, conveying the basic does not produce dust. Like lithium-ion, 3C electronics, electric core of these industries that require high hygiene, it is just right to use it.

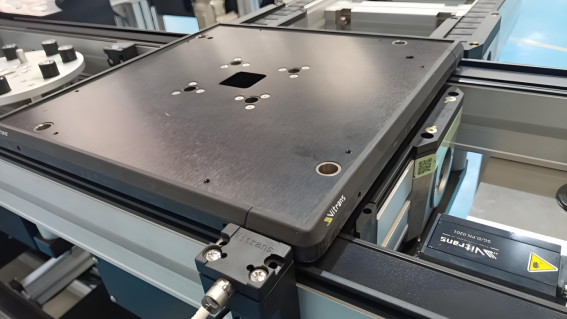

(Image source:Vitrans - Automated Conveying)

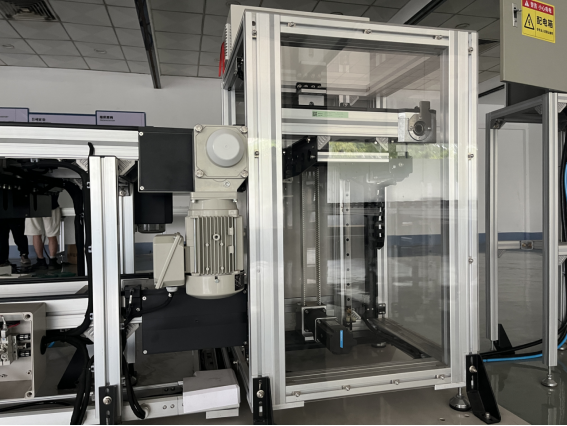

05 Elevator

What is the difference between a timing belt hoist and a rodless cylinder hoist?

All are paired with a pallet conveyor line for upper and lower conveyor devices, ourSynchronous belt elevatorIt is characterized by servo drive, which can realize accurate stop at different positions, which is very suitable for multi-layer conveying working conditions. Its pallet load can reach 30kg, we did a full load performance test, the lifting speed can reach 500mm per second, which is faster than the rodless cylinder lifting machine.

而Rodless Cylinder LifterThe whole machine is more compact, with less risk of wear and damage to the mechanical parts, and it doesn't take up too much space. For factories with limited space, this hoist is very suitable.

If you need to improve production efficiency, want to introduce conveyor lines, but are not yet clear how to choose, leave your needs, we come to you to choose a more matching conveyor equipment.