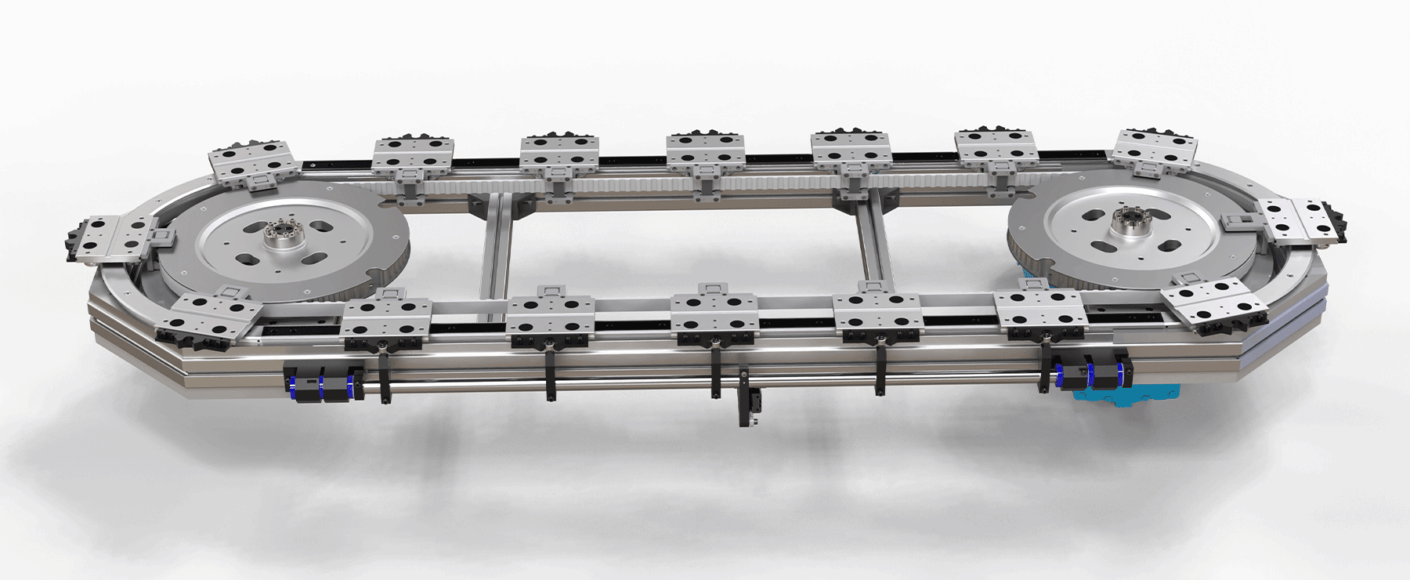

In the production lines of new energy, auto parts, 3C electronics and other industries, theRing guideconveying systemIt is not uncommon. Its role is mainly reflected in the improvement of production efficiency, reduce product scrap rate. Choose the right production process smoothly, choose the wrong may lead to frequent failures, poor adaptability and other issues. In fact, choose the right ring guide is not as complicated as we think, around the core needs of the gradual screening, will be able to accurately match their production scenarios.

Step 1: Define your core needs

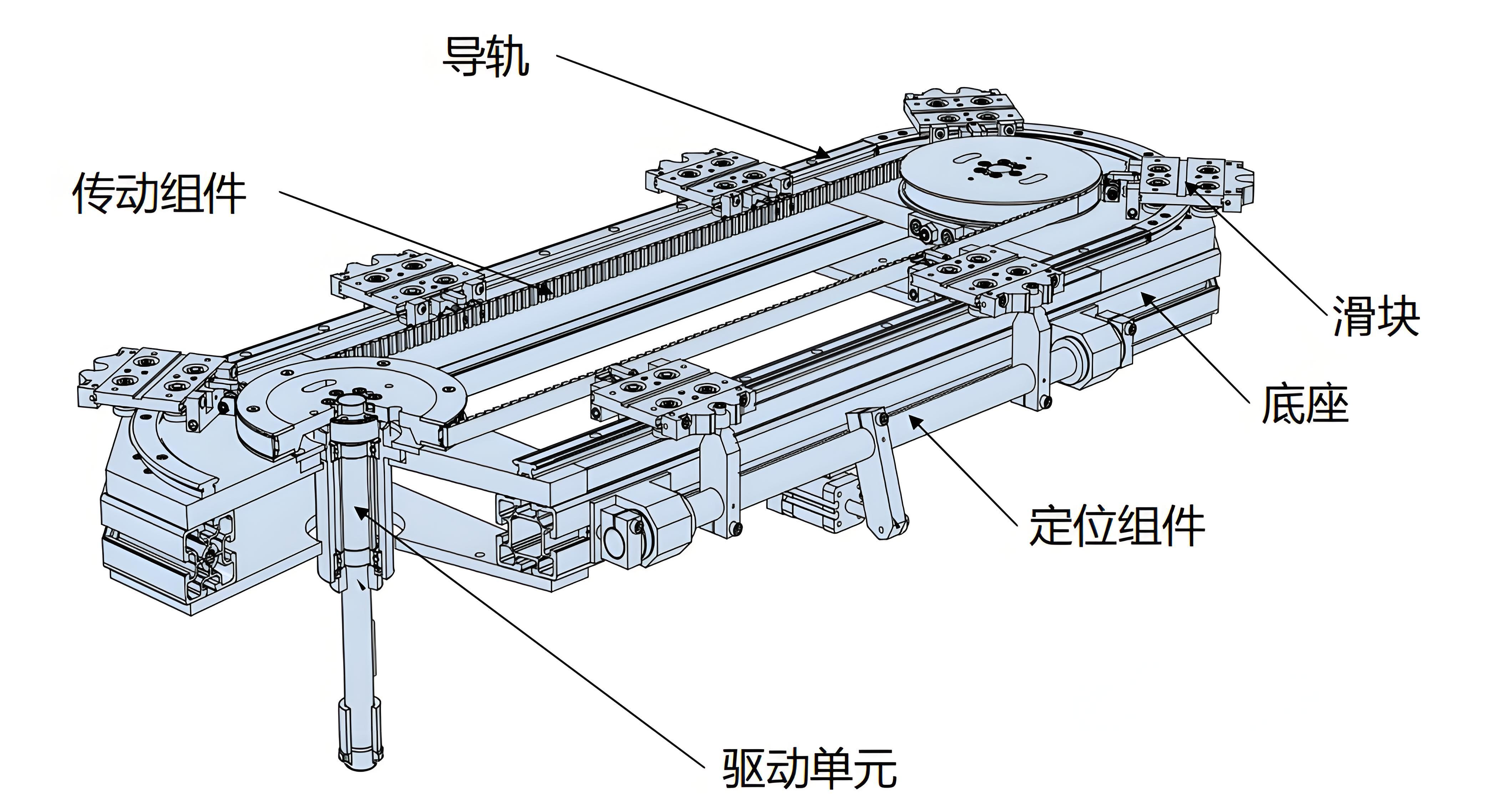

选Ring guideFirst of all, you need to find out your production needs. Know how many workstations are needed in total for the production line, which of them need precise positioning, the distance between workstations and how long it takes to switch. There is also the size of the carrier plate, the load-bearing capacity of each station, whether there is an external impact, all of which should be displayed clearly. In addition, it is also necessary to confirm the space constraints of the whole machine, such as the permissible length and width dimensions, the mounting method (horizontal or vertical), as well as the direction of rotation of the wire body, these basic information will directly determine the direction of the subsequent selection.

Step 2: Matching structure types

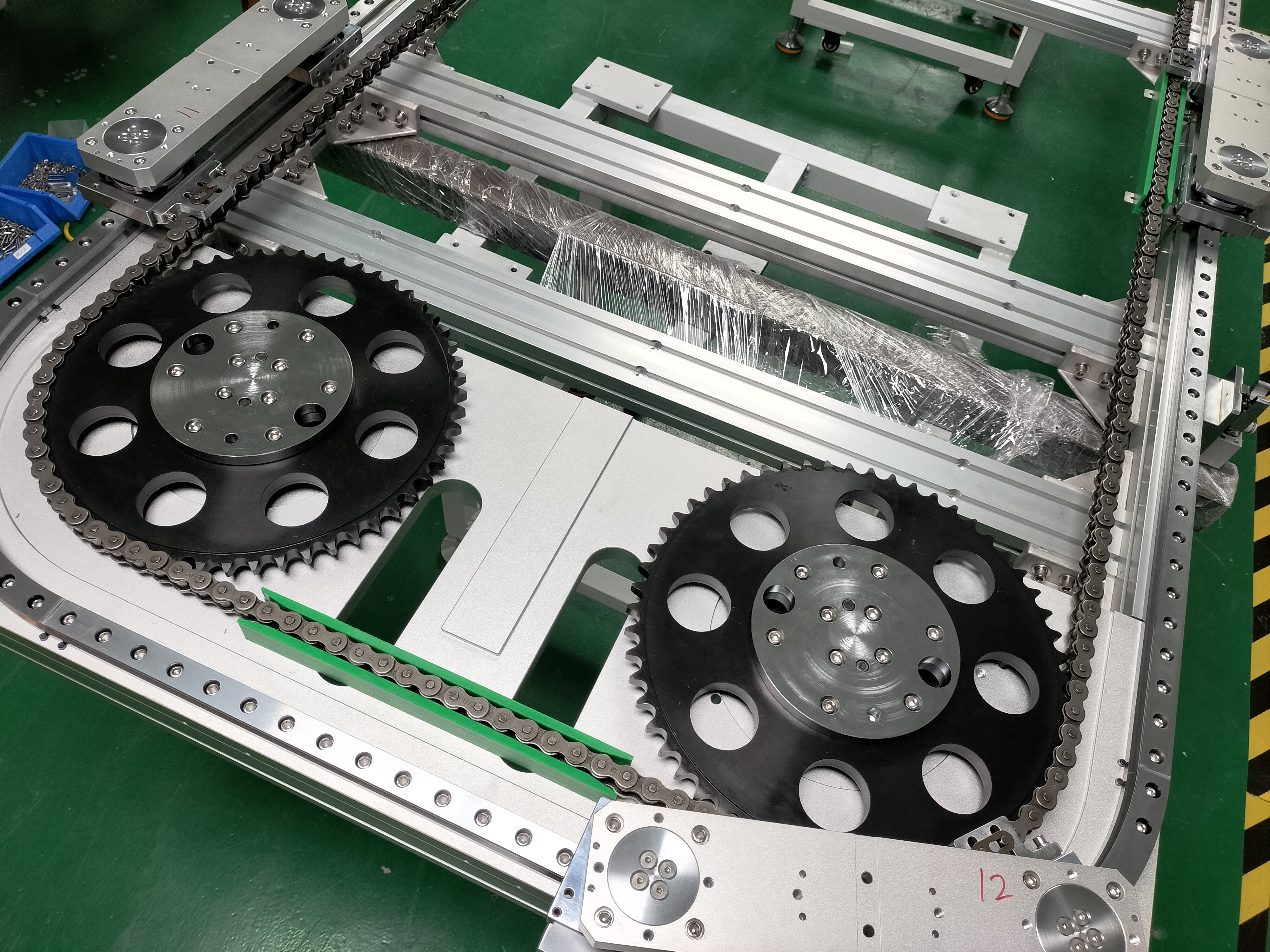

Ring guideThe type of structure should be right with their own needs. Transmission mode mainly depends on the load, the load does not exceed 50 kilograms on the choice of chain drive, suitable for large spacing, conveying a long distance of the production scene, follow-up maintenance is also convenient. Light load does not exceed 15 kilograms, but also requires a clean and dust-free workshop, choose thesynchronous belt driveThe noise level is low and there is no need for frequent maintenance. Need to install a small pitch or vertical installation, rod drive is more appropriate, smooth bends, there will not be too much impact. The shape of the line body, the need for right-angle turns on the rectangular guide, want to make the equipment continuous and smooth operation is more suitable for elliptical guide. Installation mode according to the space layout to choose, the conventional scene installed horizontally, with a special layout needs to be installed vertically.

Step 3: Check the technical parameters

The technical parameters can ensure the stable work of the equipment, not sloppy. The longest chain drive can do 80 meters, the belt drive does not exceed 5 meters, the linkage drive does not exceed 10 meters. Requirements for positioning accuracy, such as assembly, testing stations, we must choose with positioning mechanism, accuracy can be plus or minus 0.05 mm; no special requirements to choose plus or minus 0.10 mm accuracy is enough. Arc diameter should refer to the size of the carrier plate and the layout of the machine, the range from 159 mm to 1501 mm optional, the distance between the slider can be selected between 100 and 3000 mm, just to match the rhythm of production.

Step 4: Consider Supporting Services and Environmentflexibility

In addition to the equipment itself, supporting services and environmental adaptation can not be ignored. Priority is given to manufacturers who can provide the entire line of planning, installation and commissioning, customized tooling, follow-up maintenance is more secure. Working environment, high temperature, dusty or oil-contaminated workshop need to inform the manufacturer in advance, in order to customize dust, high temperature and other special designs. At the same time to confirm whether the manufacturer supports non-standard transformation, to avoid the production process adjustment leads to equipment can not be adapted.

optionRing guideThe core logic of the equipment to adapt to the production needs rather than the other way around, barely adapted. As long as in accordance with a clear demand, match the type, check the parameters, consider the matching of these four steps, combined with the characteristics of their own industry, you can choose a cost-effective, adaptable equipment. If you need a more accurate selection program, can be combined with specific production data and manufacturers to communicate, so that the ring guide really become a boost to improve production efficiency.