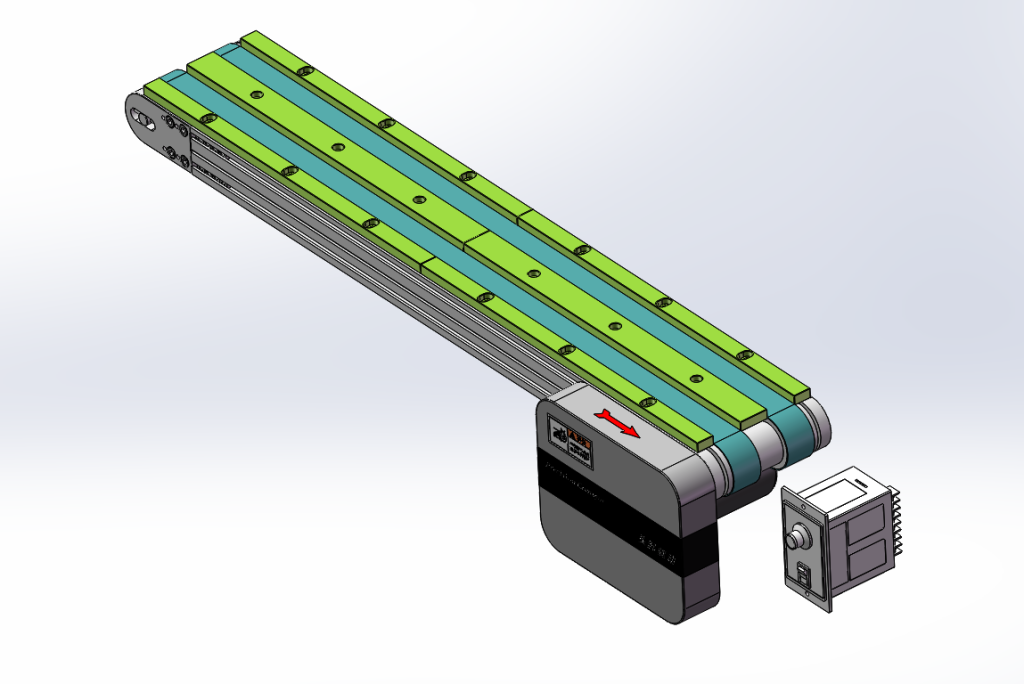

accumulativeplaten lineIt is one of the core conveying equipments of Wei Chuang Automation, focusing on heavy-duty and multi-functional adaptation, mainly used for parts/battery assembly and testing in automobile and new energy industry, with outstanding cost performance and practicality. So in the industrial automation production, theaccumulativeroller conveyorWith its practical performance, it has become the first choice of many companies.

One,Core Parameters and Functions

1.Key parameters

- Load capacity:There are two mainstream specifications, a single pallet can load 300KG-450KG, belongs to the heavy-duty equipment, can meet the bigPiece parts delivery requirements.

- Running speed:Line speeds of up to 15 meters per minute have been achieved in some cases, matching the pace of most assembly lines.

- Pallet Size:There is no uniform standard, it can be customized according to customer needs.

2.core functionality

- Smoothly conveying parts/modules, allowing materials to flow automatically between different stations and reducing manual handling.

- We are working with assembly and testing processes, such as realizing battery PACK testing, automotive motor assembly, and gearbox assembly and testing.

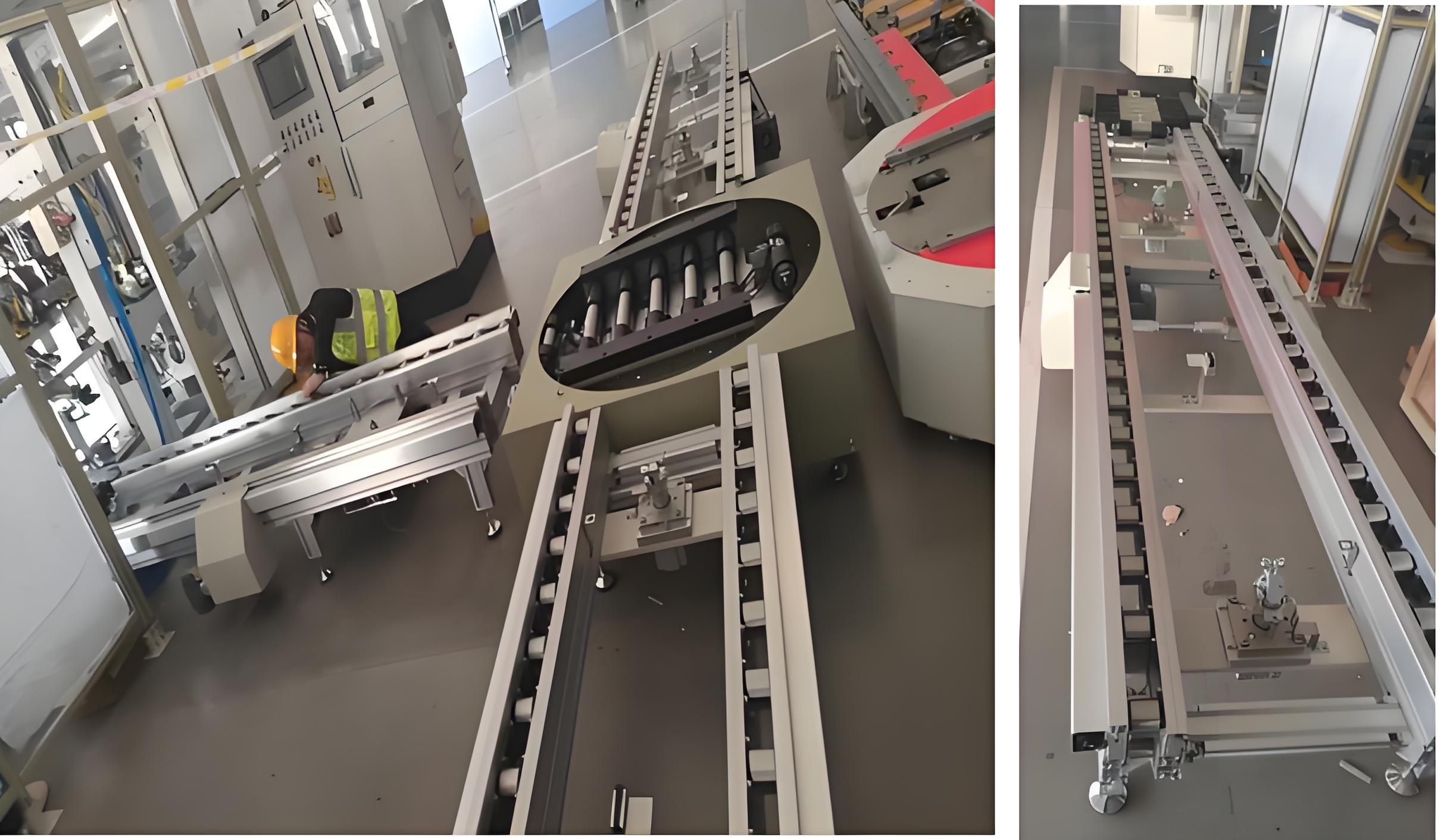

Two,Matching Auxiliary Devices

In order to meet different production requirements, the accumulating roller line will be equipped with a variety of non-standard devices to make conveying and assembly more flexible:

- Positioning and rotation:Heavy-duty jacking and positioning (allowing the pallet to be precisely fixed at the workstation), jacking rotation (driving the workpiece to rotate, facilitating multi-angle assembly), and rotary table.

- Shifting loads and lifting:Jacking traverse (allows pallets to move laterally and switch conveyor lines), Elevator (enables upper and lower conveyance of workpieces).

- Steering function:KV/90 Curve Unit (allows the conveyor line to be turned 90 degrees, adapted to the complex layout of the shop floor).

III. Accumulation of roller linesCore Advantages

Accumulation roller conveyor lineThe wide application of the company cannot be separated from its own core advantages, which allow it to adapt to the production pain points of different industries:

①Heavy-duty capability:A single pallet can support 300KG-450KG, which can easily cope with the transportation needs of large and heavy objects such as auto parts and battery modules.

②High customization flexibility:Modular design, with jacking positioning, rotation, traverse, lifting and other auxiliary devices, to adapt to the special requirements of different processes.

③Landing is efficient:It can quickly complete the layout design of the production line, and then deliver it in the specified period without delaying the production schedule of the enterprise.

④The value for money is outstanding:The price is lower than imported brands, can run stably for more than 3 years, reducing the long-term cost of enterprise use.

Four,Main application scenarios

Auto Parts Industry:

in automobile production.Accumulation roller conveyor lineIt is indispensable equipment covering the assembly process of several core components:

- Power Systems:Assembly and testing of automotive motors, reduction gearboxes, transmissions, and gearboxes

- Chassis components:Conveying and assembling of heavy-duty workpieces such as front axle components.

New Energy Industry:

With the development of the new energy industry, the accumulating roller conveyor line has become the core conveyor equipment for battery production:

- Battery PACK test line

- Battery Module Assembly Line

V. Multi-industry extended application scenarios

In addition to the two core areas of automotive and new energy, the accumulation roller conveyor line can be extended to more industries:

3c electronics industry:

Suitable for conveying and assembling large electronic equipment components, with flexible transfer devices to meet the needs of precision production.

Appliance Industry:

It is used for conveying parts of large appliances, such as refrigerators and washing machines, and helps to automate and upgrade the production line of home appliances.

Other industries:

With its heavy-duty and stable characteristics, it can be adapted to various production scenarios that require the transportation of large and heavy objects, and has a wide range of adaptability.

VI. Summary

Accumulation roller conveyor lineWith the advantages of heavy-duty, flexible and cost-effective, it has gained a firm foothold in the core industries such as automobile and new energy, and at the same time extended to more fields. For enterprises that need to solve the problem of conveying large, heavy-duty workpieces, it not only connects the various production processes, but also reduces costs and improves efficiency, and is definitely a practical choice for industrial automation production.