In industrial production, the transportation and accumulation of heavy materials has always been the core problem of enterprises - either the equipment is not load-bearing enough to adapt to heavy components; or the lack of flexible accumulation function, resulting in the rhythm of the production line is not balanced; or poor durability, frequent maintenance affects production. Andaccumulativeroller conveyorThe emergence of just targeted to solve these pain points, becoming the preferred equipment for many enterprises. Today, we will dismantle its core advantages and see why more and more enterprises choose to use it in heavy-duty accumulation scenarios.

One,Ultra-strong load-bearing performance

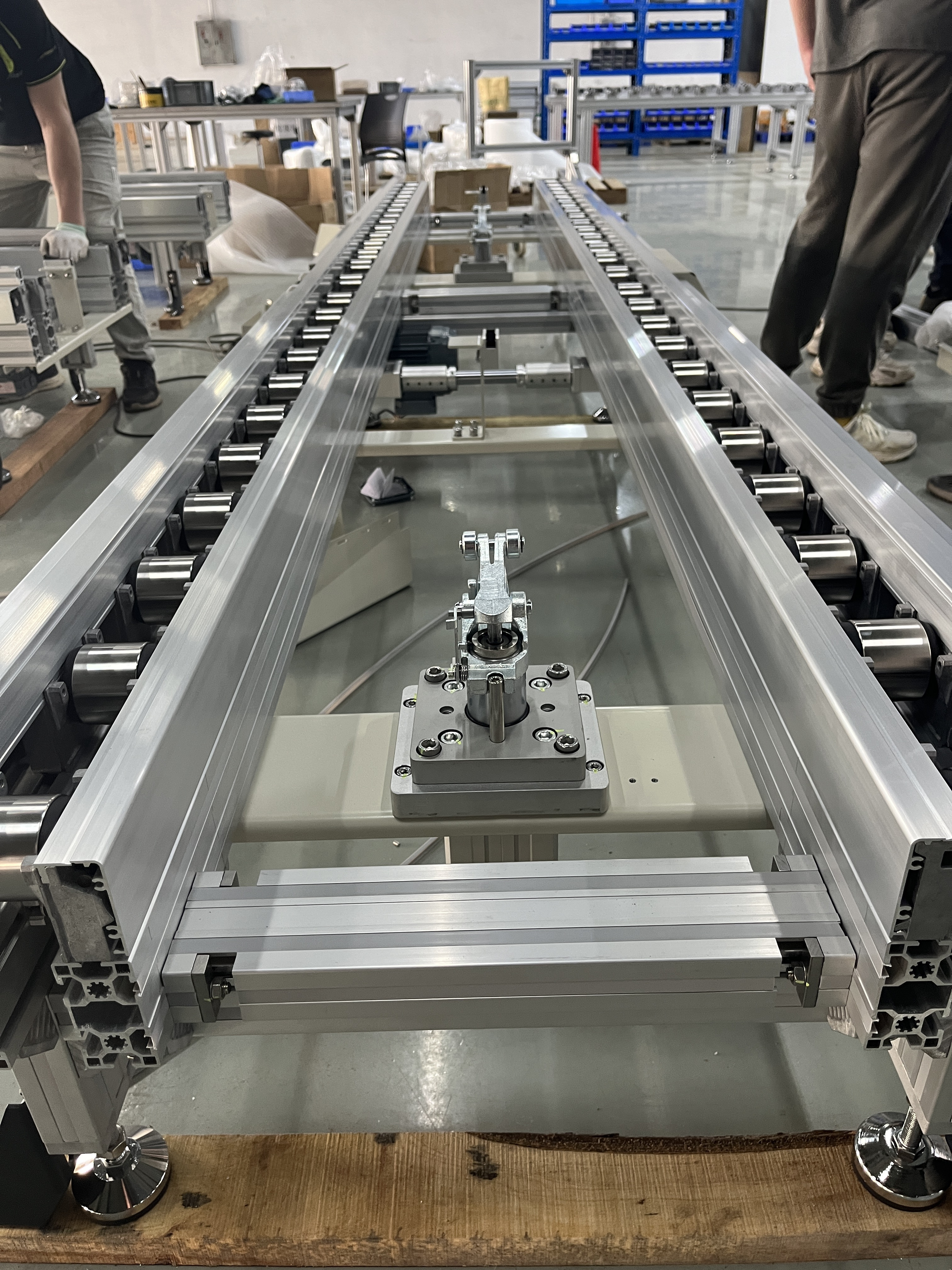

One of the core claims of heavy-duty conveying is the ability to carry heavy loads, which is why companies are choosing cumulativeplaten lineThe number one reason. A single pallet of this roller line can stably carry a weight of 450kg, which is easy for the automotive industry to carry heavy materials such as battery modules, motors, gearboxes, as well as large electronic components and bulk goods. Traditional conveyors are either insufficiently load-bearing and prone to deformation, or require more than one person to assist in handling, which is not only inefficient, but also a potential safety hazard. AndAccumulation roller lineAdopting high-strength steel frame, with thickened stainless steel roller, from the structure to ensure the stability of load-bearing, without manual intervention can realize the smooth conveying of heavy materials, which not only improves the efficiency, but also reduces the cost of manpower and safety risks.

Two,Intelligent Accumulation Function

In the production process, the inconsistency between the capacity of upstream and downstream processes is a common problem, and it is easy to pile up the material congestion or wait for the material to stop working. The intelligent accumulation function of the accumulating drum line solves this pain point. It can automatically cache materials, when the downstream process is busy, the materials can be accumulated in the drum line in an orderly manner; when the downstream process is idle, the accumulated materials will be automatically transported to the place, which perfectly balances the rhythm of the whole production line. This flexible accumulation ability allows companies to not need to configure additional caching area, and do not need to arrange for specialized personnel to coordinate the flow of materials, which greatly improves the smoothness of the production process and avoids the loss of efficiency caused by the rhythm of imbalance.

Three,Stable and efficient operation

For industrial equipment, stability is more important than speed. ThisAccumulation roller conveyor lineRunning speed up to 15m/min, with professional motor reducer drive, the conveying process is smooth and free of lagging, more than the traditional conveying method.Efficiency gainsMore than 3 times. More critically, it has strong operational stability and does not have problems such as material shifting and jamming, reducing downtime due to equipment failure. By choosing it, companies are essentially choosing a low internal consumption production model - no need for frequent downtime for adjustments, no need to spend a lot of time dealing with equipment failures, so that the production process is always running efficiently.

Four,Reduced long-term cost of use

The durability of industrial equipment is directly related to the long-term investment cost of enterprises. Accumulation roller line adopts the combination design of steel frame and stainless steel roller, which is not only wear-resistant and build-resistant, but also has good anti-rust performance. Even in the complex environment of wet and dusty workshop, it can maintain stable performance and is not easy to have problems such as parts damage and rust. Compared with ordinary equipment, its maintenance frequency is greatly reduced, no need to frequently replace parts, not only saves maintenance costs, but also reduces the production interruption caused by maintenance, long-term use of the cost-effective advantage is very obvious, which is also an important reason for enterprises to favor it.

Five,Adapt to the needs of multiple industries

When companies choose equipment, adaptability is an important consideration. Accumulation roller lines are used in an extremely wide range of application scenarios, whether it is aAuto Parts IndustryIt can be perfectly adapted to the heavy-duty component transportation of the electronics industry, the large-scale equipment transmission of the electronics industry, or the bulk cargo transfer of the logistics industry. It can adapt to the clean and tidy assembly workshop, but also to cope with the complex environment of warehousing and logistics, without the need for enterprises to configure separate equipment for different scenarios, to truly realize the “one machine multi-purpose”. This wide range of adaptability allows enterprises to maximize the value of their investment in equipment, which is especially suitable for production enterprises with diversified businesses and complex scenarios.

summarize

From superb load-bearing to intelligent accumulation, from stable operation to durable adaptation.Accumulation roller conveyor lineEach of the core strengths of the company hits the exact right spot in the heavy-dutymaterial handlingin the actual needs. For enterprises with heavy-duty accumulation needs, choosing this roller line is essentially choosing an efficient, stable and low-cost production mode. If your enterprise is troubled by the problem of heavy-duty material conveying and accumulation, you may pay attention to this accumulating heavy-duty roller line, which may become the key to help you optimize the production process.