In the busy assembly line of a logistics sorting workshop, the clean production area of a food factory, or even the filling station of a daily chemical factory, you can always see theflexographicchain conveyorThe presence of this automated conveying equipment can span a wide variety of industries. It has no fancy gimmicks, all rely on solid design and performance to stand firm, in the end what makes it so versatile? Today, let's talk about this practical conveying equipment from the composition, advantages and industry adaptation logic.

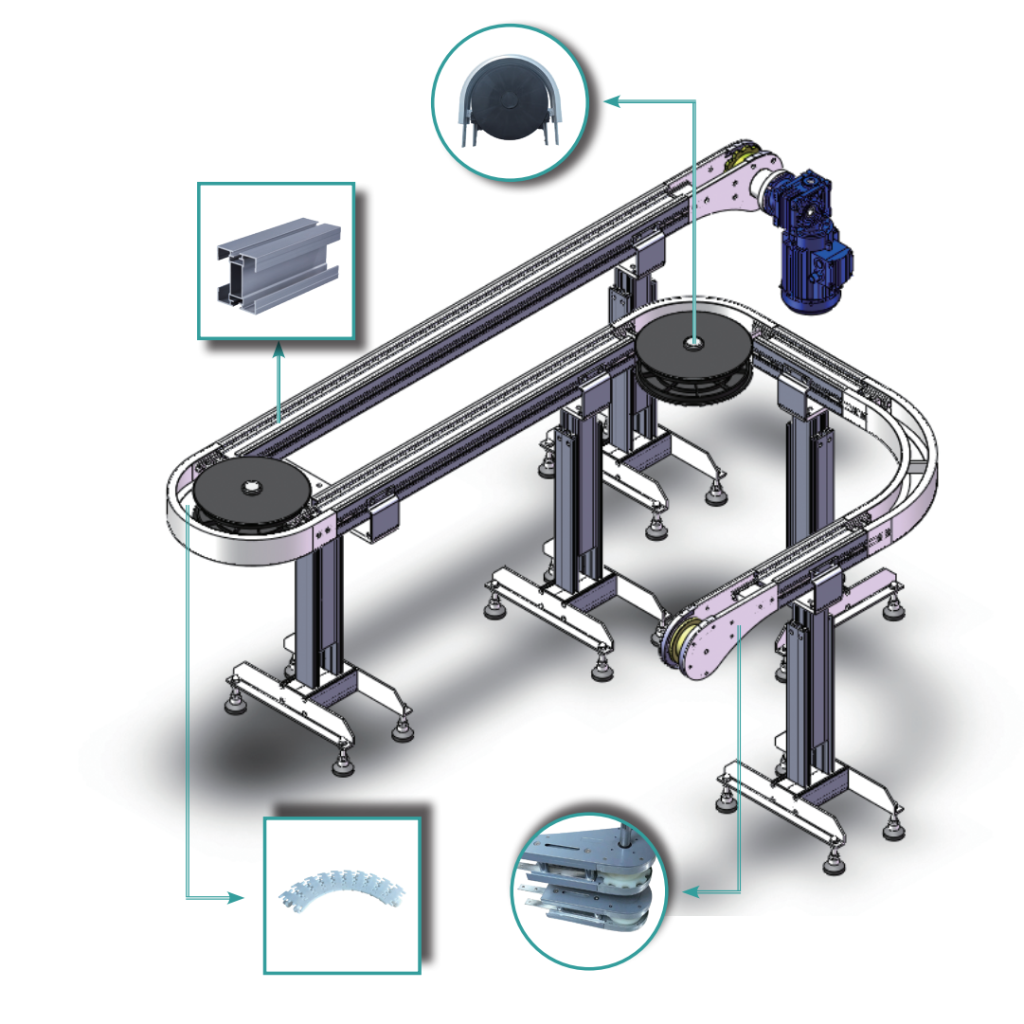

I. Core components

Flexible chain conveyor lineThe reliability of the chain is actually derived from its solid materials and flexible accessories. The main conveyor chain plate is made of modified polyoxymethylene resin (POM), pure white appearance, no corrosion or rust; with the frame is A6063 aluminum alloy, the surface is also made of anodic oxidation treatment, which is both strong and clean. The key pin is S5304 stainless steel, wear-resistant and anti-manufacturing, long-term use down is not easy to deformation fracture.

The accessories are both universal and customized: the conveyor beam has various specifications from 45mm to 300mm, and the standard length of 3m can be flexibly spliced to fit different widths of chain plates; there are two kinds of driving devices, the full-sealed head drive can cope with the chain plate of 43295mm, and the plastic driving head is suitable for the chain plate of 43103mm, so it can cover light and heavy loads; the elbows are also flexible, and can be turned horizontally from 30° to 90° and vertically from 5° to 90° with a minimum radius of only 150mm. The elbow is also very flexible, from 30° to 90° horizontally and 5° to 90° vertically, and the minimum radius is only 150mm. Together with the bracket, guardrail, friction strip and other small accessories, it can be assembled according to the needs of the production site.

II. Core strengths

1,Clean and maintenance-free, suitable for high-standard scenarios.

When it comes to its advantages, I am afraid that the most worrying thing is clean and maintenance-free. No extra lubrication is needed for the equipment to run, so there is no oil contamination, which is completely in line with GMP production norms - this is simply a necessity for food, pharmaceutical and cosmetic industries that have high hygiene requirements. And the chain plate and frame corrosion and moisture, sometimes directly rinsed are no problem, daily maintenance without effort, maintenance costs naturally dropped a lot.

2,Ultra-quiet operation, more comfortable workshop environment

Noise at work is less than 30 decibels, almost as quiet as in a library, which will not interfere with the production of precision instruments, but will also make the working environment more comfortable for shop workers. For those noise-sensitive scenarios, such as laboratory supporting production lines, this may be a plus.

3,Compact and compact, small space can be played with

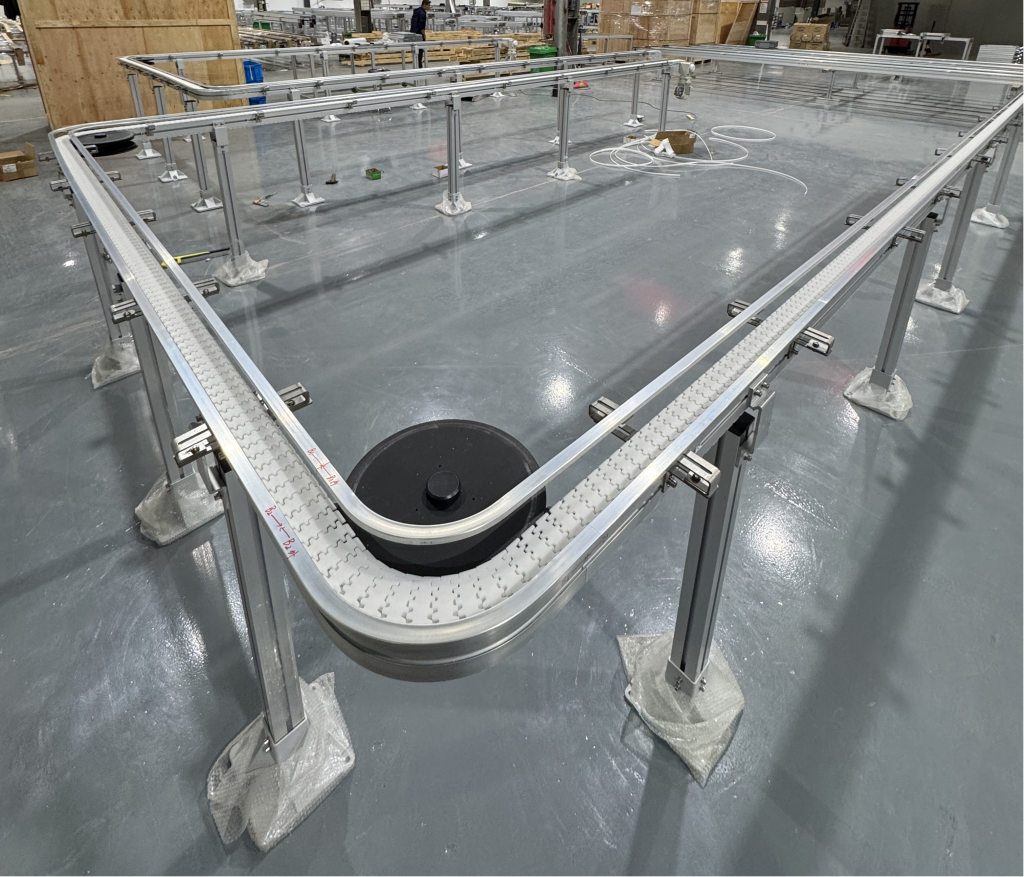

modular designParticularly pleasing to the eye, like building blocks can be disassembled and assembled at will, whether it is horizontal conveying, vertical lifting, or turning around, in the 3D space can be dealt with. Plus its minimum turning radius is small enough, climbing ability is not bad, even if it is a narrow site, can be set down, run smoothly, small space production conveyor problems, it is a solution.

4,Super easy to install, conveys steadily without tipping over

No need for complicated special tools, a single person with commonly used hand tools can complete the disassembly and installation, and later want to expand or remodeling lines, but also do not have to go through a lot of trouble. Its working temperature can cover 20 ° C to +60 ° C, the highest conveying speed can be up to 50M / min, linear conveying up to 40M, the most critical is that the material in the conveying process will not be tipped over, do not slip, even if it is a precision parts or containers containing liquids, but also can be sent to a stable.

5,Functionality can be expanded and complex needs can be met

In addition to basic conveying, it can also realize a variety of conveying methods such as tray, push, hang, clip, etc. Collecting, diverting and sorting these functions can also be integrated into it. If you needAutomation upgradesThe production line can be composed of a complete production line by adding a pneumatic and electric automatic control device, which can improve the production efficiency to a certain extent.

III. Industry Adaptation

How its strengths just match different industry pain points:

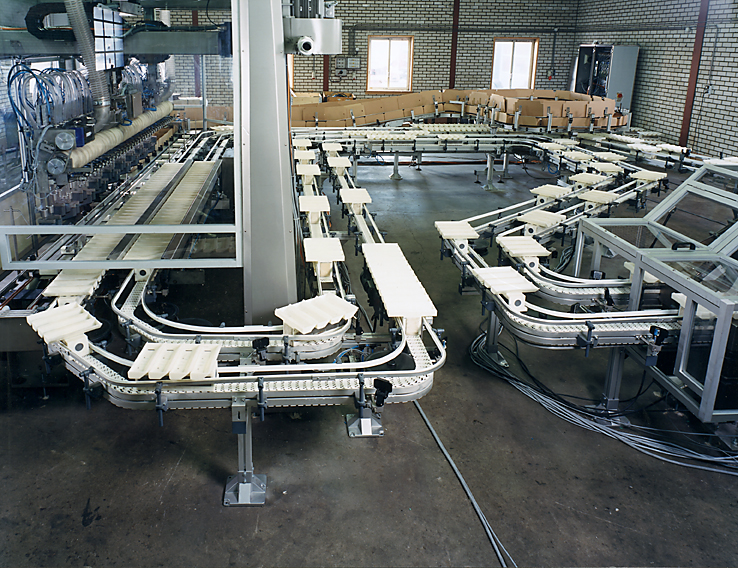

1,Logistics and courier industry:Sorting systemsThe paths are often more complex, theFlexible chain conveyor lineThe flexible layout of the ability to just fit; small turning radius can improve site utilization, stable conveyor can also reduce the express breakage - about 5 meters of the line, choose a 400-watt motor is enough, or look at the actual load.

2,Food/Baking Industry:Clean and dirt-free, in line with GMP norms is a hard requirement, it just meets the standard; the characteristics of direct rinsing makes cleaning more convenient and avoids food contamination, no matter it is a bread production line or beverage conveying, it can meet.

3,Daily chemical/pharmaceutical industry:Toothpaste, skin creams, pharmaceuticals and these products require a high level of cleanliness in the production environment. Its corrosion-resistant material and stable conveying ability can prevent liquid or paste materials from leaking, which is reassuring.

4,Industrial Manufacturing:Bearing factories, electronic factories, tire industry, the need for precision and stability of the conveyor, which can be linked with a single machine to form a complete production line, but also supports the segmentation or overall control, to a certain extent, reduce labor intensity.

From clean rooms to logistics warehouses.Flexible chain conveyor lineRelying on not exaggerated propaganda, but clean, quiet, flexible, stable and these real values, to solve the conveyor pain points of a number of industries. This practical and reliable conveying equipment, with its own strength, has become an indispensable assistant on the modern production line.