In automotive parts drying, shoe baking, new energy battery curing these high-temperature processes, ordinary conveyor lines often do not last long - either softened and deformed, or frequent jamming and shutdown, the life is even more visible to the naked eye to shorten. Anddoubled speed chainconveying lineHowever, it can pass such a test stably and become the main force of transportation in high temperature environment. Today, we will combine the actual scene, talk to you about its high-temperature resistance advantages, core logic, and then share a few real cases, so you can understand why it can easily cope with high-temperature challenges.

One,Speed Chain Conveyor LineCore Strengths and Composition

The core of the chain can do stable conveying under high temperature is still relying on the actual design and material selection, taking into account the stability and adaptability, with more peace of mind:

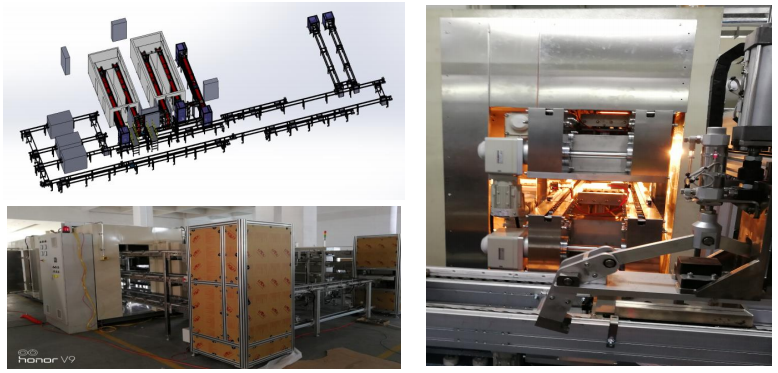

Its core transmission components selected high temperature steel chain, the frame is used stainless steel profiles, both corrosion-resistant and wear-resistant, the probability will not be like ordinary materials in the high temperature softening failure. Structure using modular assembly, the longest single section can be up to 6 meters, want to put together more than 30 meters is no problem, no matter how the layout of the workshop, basically can be adapted. And the load coverage is very wide, from 200kg light workpiece to 4000kg heavy parts can be sent, the line speed can also be adjusted, with the high temperature process of the beat requirement is just right, the fastest single line beat can be up to 1.5 seconds / piece, the efficiency of the complete keep up.

Two,The core reason for the high temperature resistance of the speed chain conveyor line

Ordinary conveying line into the high-temperature environment once the water and soil is not suitable.Speed Chain Conveyor LineBut it can run stably, in fact, the key lies in 3 points of design:

The first is the right choice of material.The chain is made of high-strength steel material, and it also undergoes special heat treatment, so that even under the high temperature environment of 150℃, it can maintain rigidity and will not be easily softened, stretched or broken; the frame and the guide rail are also stainless steel, which is resistant to high temperature and corrosion, and will not be easily deformed under the high temperature baking for a long period of time.

Secondly, the structure has been optimized for anti-deformation.The wire profile is deliberately thickened and the assembly process is strictly controlled to minimize the effect of thermal expansion and contraction at high temperatures; some key connections are also added with thermal compensation structures to avoid jamming or precision shifts due to temperature changes.

Finally, the protective properties are done properly.The chain adopts semi-wrapped design, which can not only prevent high temperature dust and debris from being rolled in, but also reduce the direct erosion of high temperature on the transmission parts; some of the models specially designed for high temperature scenarios will also be equipped with heat dissipation auxiliary structure, so that the service life can be extended by one more cut.

Three,Typical of high temperature environmentsApplication Cases

The high-temperature resistance of the speed chain has long been battle-tested in a number of industries, so let's look at a few examples of the real landing:

for exampleAuto Parts IndustryThe motor assembly line of a manufacturer needs to be dried in a high temperature oven at 150℃, and the holding time is 20 minutes. After replacing the high-temperature-resistant speed chain, the line runs smoothly throughout the entire process, a single pallet can support 90kg, a single line beat 15 seconds, perfectly adapted to the assembly-glue coating-high-temperature drying of the continuous process, so far more than 3 years of stable operation, without a single failure.

Another example is the dispensing curing process in the shoe industry, where the temperature has to reach 120°C, and many manufacturers will use theDouble Speed Chain--The upper layer is responsible for the high temperature baking and conveying of shoes, and the lower layer is specialized in caching the return empty trays. The line is not only high-temperature resistant and odorless, but also has high conveying precision, which can avoid the shoes from shifting during the baking process, and the capacity of a single line can be increased by about 30%.

there areLithium industryThe module testing line of a battery enterprise requires 100℃ for drying process and 300kg load for a single pallet, and the speed chain with heavy-duty jacking positioning device can maintain ±0.5mm positioning accuracy under high temperature environment, which can just meet the demand for accurate testing of battery modules after drying, and the PPM of a single line can be up to 36 pieces.

summarize

In the end.Speed Chain Conveyor LineIt can solve the high temperature working condition, relying on the right policy - the right material, structure optimization, and then customized according to the scene. From automobile, shoe-making to new energy industry, it has solved a lot of high-temperature process conveying pain points by virtue of high temperature resistance, stable operation and long service life. Whether it is conveying in the drying oven at 150℃ or in the workshop working condition at high temperature for a long time, as long as it is targeted and customized, it can basically be adapted. If your production chain is also facing high-temperature conveying problems, the speed chain conveyor line may be a practical and cost-effective choice.