Modern industrial production, conveying system is like a series of processes of the “blood vessels”, once the problem, the entire production rhythm must be chaotic. Many factories are still fighting with the traditional production line: conveyor jamming, carrying heavy loads, positioning is not allowed, from time to time because the equipment is not in tune with the stop line, the efficiency of a direct discount. Anddoubled speed chainline, is precisely the right choice to solve these troubles, especially Dongguan CityWei Chuang AutomationThis pallet ofSpeed Chain Conveyor Line, with years of industry precipitation, has saved a lot of good reputation in the market.

One,Core Advantages

The core advantage of Speed Chain just hits the pain point of traditional production line.

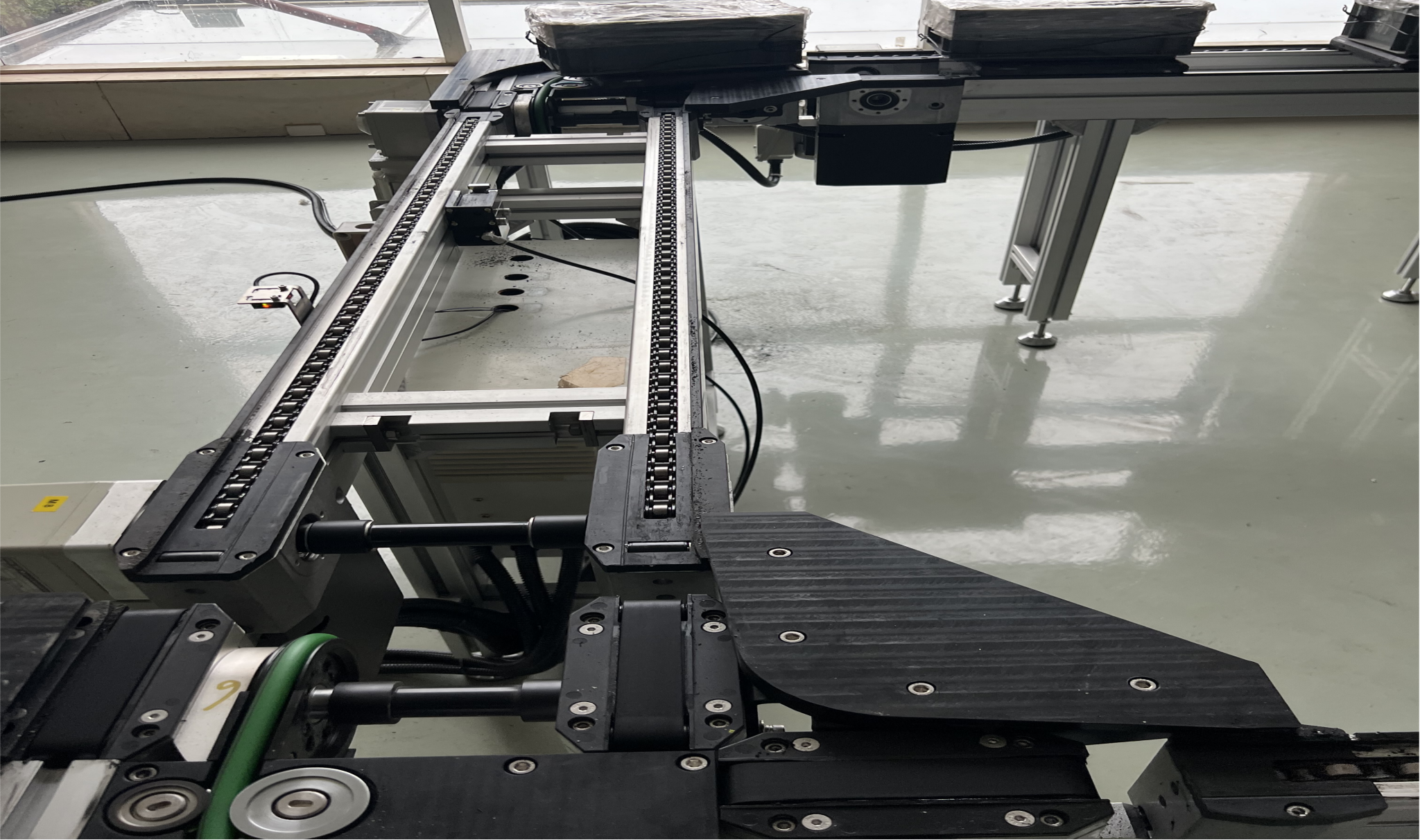

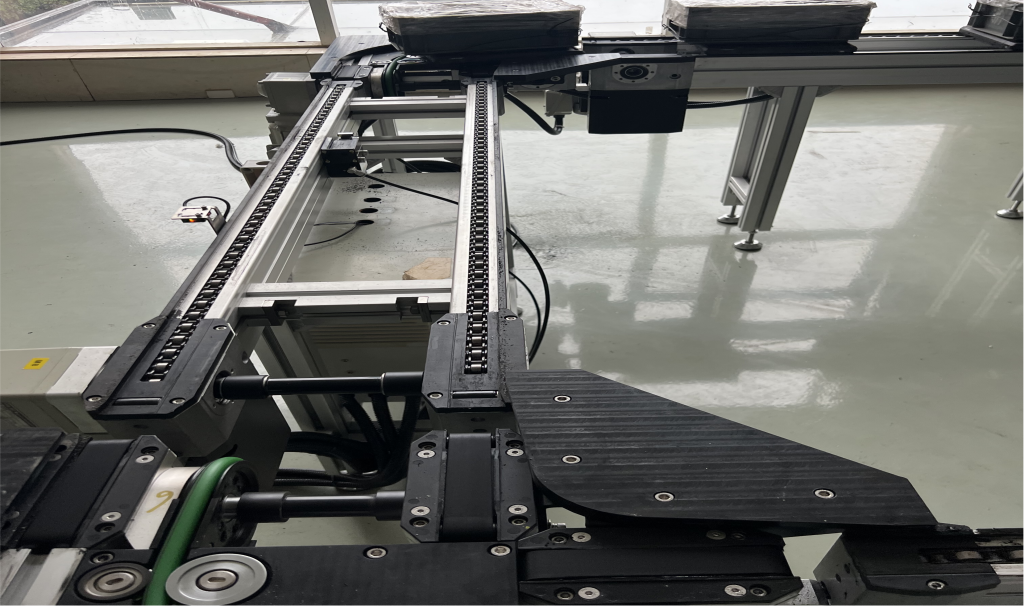

Load capacity is very stable, whether it is light materials or heavy parts - Wei Chuang's products, a single pallet load can be up to 145KG, 300KG, and even 450KG, such as battery modules, automotive parts and such products conveyor, can fully meet.

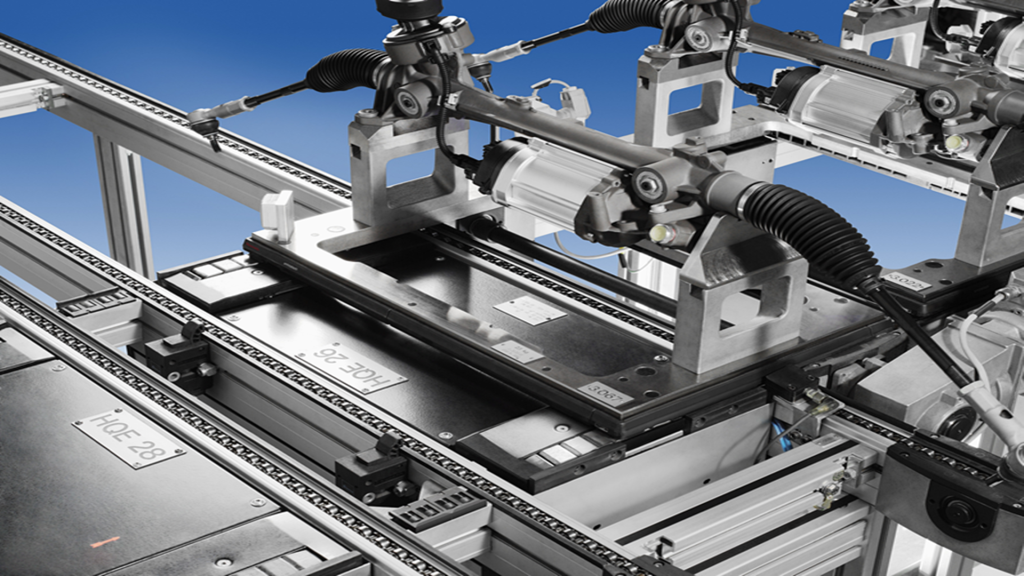

Positioning accuracy is also not ambiguous, jacking rotation indexing positioning can be accurate to ± 0.05 °, the rotor conveyor is even finer to ± 0.015 mm, which is very critical for assembly, testing such precision processes. And it ismodular designThe degree of flexibility is very high, according to the factory site can be changed into a U-shaped, circular or upper and lower structure, Wei Chuang can even get the layout of the production line in 1 day, 2-4 weeks on the completion of the delivery, which greatly reduces the time of the project on the ground. More rare is that it can run stably for more than 3 years, the price is also lower than the imported brands 30%, practicality and economy is considered to be balanced.

Two,Industry Applications

Its actual performance in various industries is really remarkable. The automotive industry is considered one of its main battlefield, Wei Chuang for automotive motor assembly to do the 50-meter circular production line, to achieve fully automated operation; 46-meter-long automotive shock absorber assembly line, with the upper and lower design, 16 workstations work in an orderly manner, but also special space-saving. The new energy field is also inseparable from it, the battery module test line relies on the heavy-duty doubling chain, the jacking and positioning, traverse and rotation of these functions are integrated together;

The PACK test line for energy storage batteries contains 21 stations, which is perfectly suited to the rhythm of high-speed production. In the home appliance, 3C electronics, shoe industry, it is not absent - for example, fully automated shoe dispensing and curing production line, with a double-layer speed chain design, the upper layer is responsible for the process operation, the lower layer of the cache of empty trays, the upper layer is responsible for the process operation, the lower layer of the cache of empty trays, the lower layer is responsible for the process operation.Space utilizationA quick lift.

Third, Wei Chuang automation manufacturers strength

A reliable product always has to be backed by a strong manufacturer.Wei Chuang AutomationIt is not an empty talk to become an expert of conveying solution in the whole industry. From 2012, we started to do market research, study foreign successful cases, accumulate the needs of various industries, and then later product development, standardization and modularization upgrade, step by step to the present, has long formed a mature production system. Its speed chain products are all “ground” out in actual projects: the 30PPM beat of the battery core assembly line and the stable operation of the 140-meter line for automotive electronics assembly are all real market tests. Now it is inglobal presenceWith multiple sales points and cooperative customers such as BYD, Ningde Times, Changan Automobile and other well-known enterprises, even overseas projects can provide products that meet the European CE certification, so you don't have to worry about compliance.

IV. Summary

For companies that want to upgrade their automated production lines and get rid of unstable conveyor troubles.Speed Chain Conveyor LineIt is undoubtedly a cost-effective choice. And choose the right manufacturer is even more critical, like Wei Chuang can cover the whole chain of R & D, production, after-sales, can make the production line upgrade a lot less detours - 24-hour response to after-sales service, standardized quality control, coupled with a wealth of experience in the industry customization, can ensure that the conveyor line long-term stability to play a role. Say goodbye to the traditional production line of those bad things, may wish to start from a reliable speed chain conveyor line, to the production efficiency to add strength.