In recent years, competition in the beverage industry has long entered a white-hot stage - health standards are stuck strict, the workshop site is crowded, conveyor efficiency does not go, these pain points let many manufacturers into the involution of the dilemma. Andflexographicchain conveyorWith its wear-resistant and corrosion-resistant engineering plastic material, coupled with the flexiblemodular design, just poking at the core needs of beverage production, giving manufacturers ofAutomation upgradesPaved a smooth road.

One,Flexible chain conveyor lineconstituents

The core components of a flexible conveyor line, each of which is precisely adapted to the beverage production scenario:

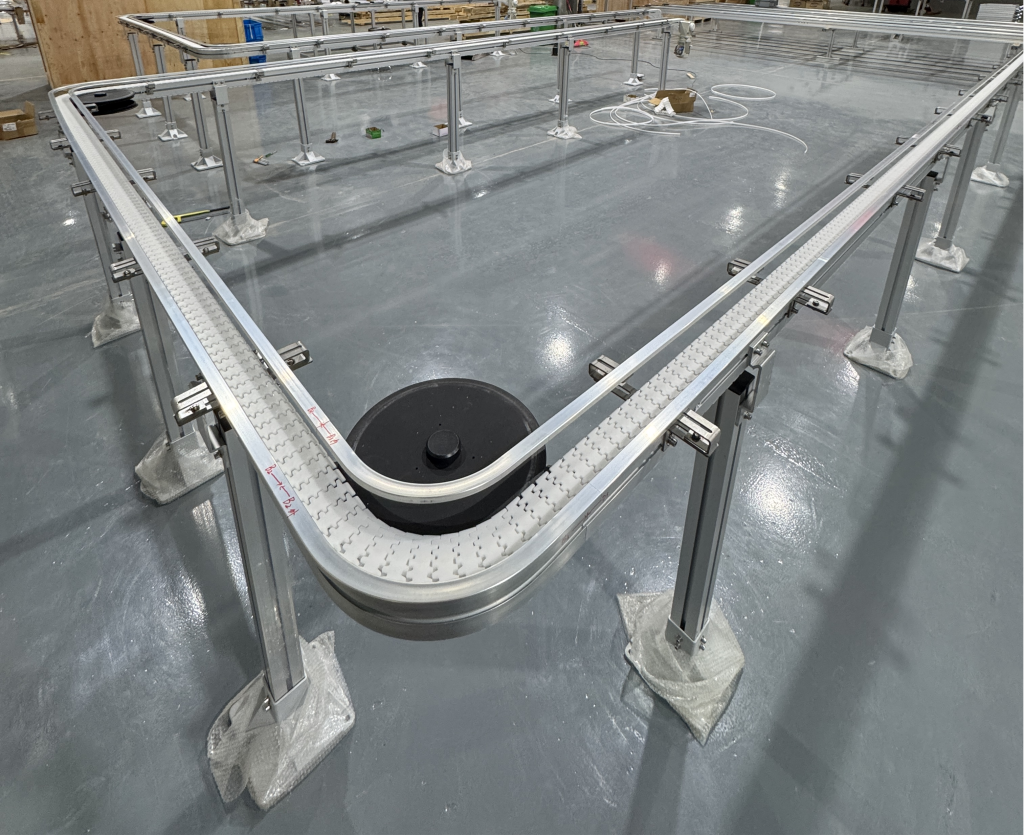

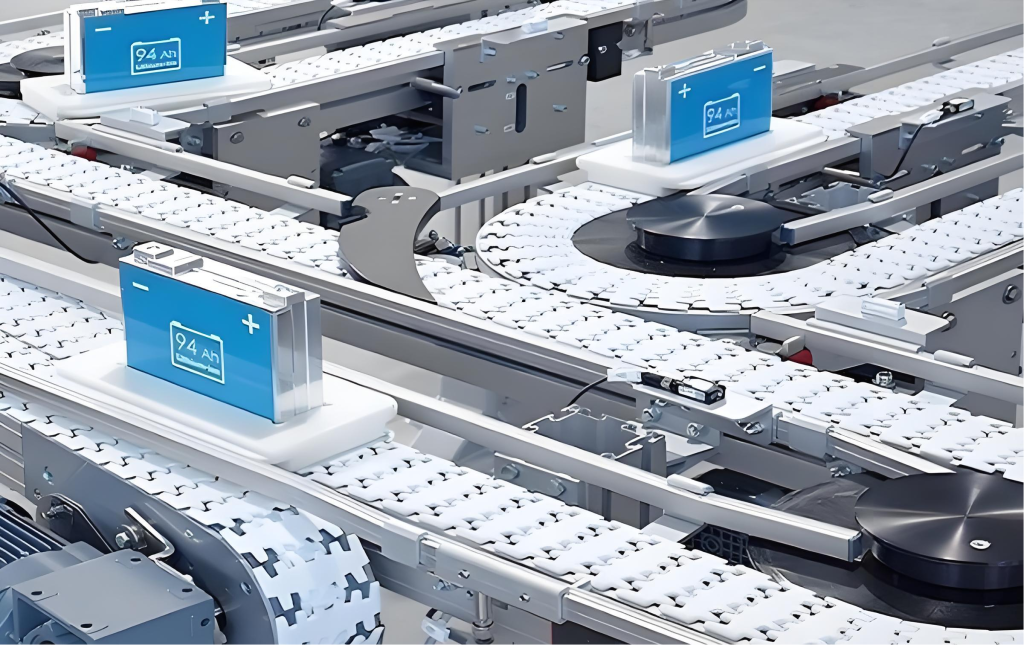

- Conveyor chain is the core, made of modified polyformaldehyde resin (POM), there are many types of flat chain, universal chain, etc., relying on the exquisite hinge with, can be in the horizontal and vertical direction of free bending, no matter it is glass bottles, PET bottles, or cans, can be steadily transported without deviation;

- The conveyor beams and racks are anodized aluminum alloy profiles, light and strong, and are also divided into standard, reinforced and light-medium-heavy types, which basically cover the capacity needs of both small workshops and large factories;

- The drive unit is made of aluminum, formed by powder metallurgy die-casting, with single drive and double drive available, with stable power output, fully capable of keeping pace with the continuous production of beverages;

- Auxiliary parts such as guide rails, elbows at various angles (30°-90° horizontal, 5°-90° vertical) and liquid trays effectively prevent bottles from tipping over and spilling, making the conveying process clean.

Second, the core advantages of flexible chain plate line

Even more noteworthy are its core benefits, which fit the needs of the beverage industry almost perfectly:

The chain plate is pure white POM material, with anodized aluminum alloy frame, running without extra lubrication, also saves the effort of regular maintenance - no oil, not to mention that it will not fall off the powder and chips, in full compliance with food-grade GMP specifications, and can even be cleaned directly with water rinsing, soaking, so that the hygiene of the production of beverages to meet the standard is no longer a struggle.

The operation is also particularly quiet, the noise is less than 30Db, almost the quiet level of the library, will not be as noisy as the traditional conveyor line that people have a headache, the operation and inspection work in the workshop can also be more focused.

For beverage manufacturers with narrow sites, its dexterous layout is simply a savior. The modular design can be disassembled and assembled at will, and the minimum turning radius is only 150mm, so it can realize horizontal, inclined and turning 3D space conveying in a narrow workshop, and utilize the limited space in a clear way.

Installation and maintenance is also hassle-free, without special tools, a person with common hand tools can complete the disassembly and installation. Moreover, the components are highly versatile, and can be flexibly expanded at any time if they want to expand production capacity at a later stage, which reduces a lot of time and labor costs to a certain extent.

Stable performance of this point is also very critical, the chain plate wear-resistant and corrosion-resistant, pins with S5304 stainless steel, running up a stable and steady, to avoid beverage bottles tipped over, slipping or collision damage, especially suitable for bottled beverages such as the fear of falling products.

In addition, it can flexibly integrate a variety of functions, can be customized to support, push and other conveyor methods, plus the collection, diversion, sorting of these functions, and then installed a pneumatic or electric self-control device, whether it is carbonated beverages, fruit juices or bottled water, the production line can be adapted to different categories.

Application Scenario of Flexible Chain Plate Line

Look at an actual case:

A large bottled beverage companies, before the traditional conveyor line tossed enough - shop equipment crowded, rigid layout, conveying bottles always tipping, equipment wear and tear off the powder also affects the health of the sampling, maintenance is frequent but also delayed production.

pull intochain conveyorAfter that, through modular combination, it realizes the seamless connection of feeding-cleaning-filling-labeling-boxing, the small turning radius design revitalizes the narrow space, the no-chip contamination makes the sanitary sampling pass rate directly rushed to 100%, and the maintenance-free feature also reduces the downtime of 90%, and the conveying efficiency is also improved by 30%, which is perfectly adapted to the demand of its multi-category and high productivity.

In the end.Flexible chain conveyor lineIt is not a simple conveying tool, but a powerful helper for beverage manufacturers to break through in the involution. With the advantages of clean, quiet, dexterous and stable, it accurately solves the pain points of beverage production, and helps manufacturers toreduce costs and increase efficiencyIt is the ideal choice for automated production lines in the beverage industry, as it helps to upgrade quality.