Heavy-duty conveying choose the right equipment, production line efficiency directly doubled. In the automotive parts assembly workshop, new energy battery production line, the stability of heavy-duty conveying equipment is like the foundation - the foundation is not firm, the subsequent assembly, testing links are easy to fall off the chain. Dongguan(reddish jade)Automation Equipment Co., Ltd (Vitrans), as a solid industry-wide conveying solution expert, relying on a 25,000m² production base, 200+ professional team, and the hard power of annual sales of 200 million +, launched theaccumulativeroller conveyorIt has long been a must-have equipment for heavy-duty conveying in many well-known companies.

One,Hardcore parameterization, tailored for heavy-duty scenarios

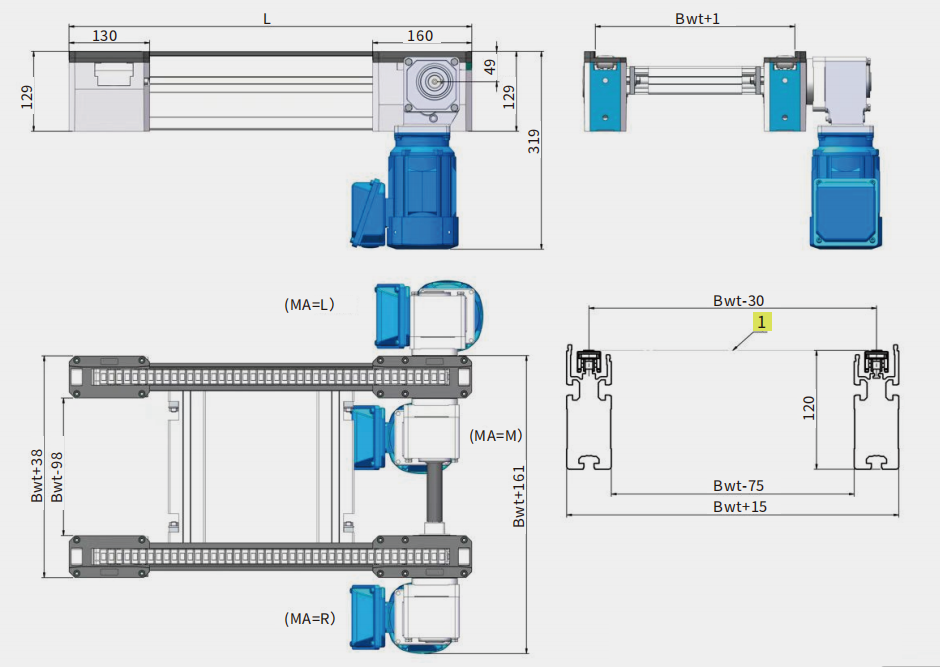

this oneAccumulation roller conveyor lineThe parameters of the machine are simply tailor-made for heavy-duty scenarios. The overall maximum load can reach 4000kg, and a single set of rollers can also carry 200kg, such as battery PACK, automobile front axle workpiece, it can be transported steadily; conveying speed can be up to 15m/min, with themodular componentThe production line flow efficiency naturally do not have to worry about. Size is also very flexible, conveying width 300-1200mm, length 1000-6000mm, if there is a special demand, also supports non-standard customization, can match different specifications of the pallet. The drive mode is bevel gear spindle drive, coupled with stainless steel roller and high-strength aluminum profile line body, electrical specifications to adapt to 220/380AC voltage, stable and durable operation. What is more considerate is that it can also be matched with heavy-duty jacking and positioning, traversing, rotating and other units, the application of the scene immediately broadened a lot.

Two,Full coverage of application scenarios, used in multiple industries

What industries and scenarios does it actually adapt to? The answer is actually quite broad.

在Lithium industryIn the battery PACK test line, module assembly line, you can always see its figure - a single tray can carry 300-450kg battery components, from beginning to end to complete the whole process of assembly, testing;

Auto PartsIn the industry, from the motor and gearbox to the assembly of the front axle and gearbox, it is able to hold a steady hand, relying on the accumulative design to make the connection between the processes silky smooth and precise.

In addition, it can also meet the heavy-duty transportation needs of 3C electronics, home appliances and other industries. At present, Ningde Times, BYD, Changan Automobile, Geely Automobile, many of these well-known enterprises, many of which have incorporated it into the core production line, the application scenario covers the assembly, testing, transit and other key links.

Three,Understands heavy-duty needs better than traditional conveyor lines

Bevel gear spindle drive can be more reliable than the traditional chain drive, running up no noise, maintenance also saves time, but also can manually adjust the friction, high energy-efficiency design can also help enterprises save a lot of operating costs. More importantlymodular designAll components are pre-assembled and can be flexibly combined through a single interface, greatly shortening the production cycle. There is one more thing that cannot be ignored, its precise control ability - the matching heavy-duty jacking and positioning unit, the repeat positioning accuracy can reach ±0.3mm, and the 90°turn of the rotary table only takes 4S, which can fully meet the demand of high-precision production.

Four,Key questions and answers

Question 1: What is the core technology of the Vitrans Heavy Duty Accumulator Conveyor Line? What are the core advantages over conventional drives?

Answer: The core technology is the bevel gear spindle vertical shaft drive structure, all rollers through the distributed drive shaft to achieve synchronized power transmission. Advantages over traditional chain drives include:

①Noiseless operation, optimizing the industrial environment;

②Easy maintenance, reducing the need for lubrication and grease maintenance;

③High energy efficiency, low drive power requirement reduces energy consumption;

④The friction force can be adjusted manually to suit different load scenarios;

⑤ Compact structure, the drive shaft is located below the conveying surface to avoid external interference, suitable for all-weather use.

Question 2: A new energy enterprise needs to build a battery module assembly line with a load of 350kg and a pallet size of 800*800mm, what products should be selected? What are the key parameters to be met?

Answer: The products that should be selected and the parameters required are as follows:

①Core Conveyor Line: TS7 Series Accumulation Typeplaten line(Width ≥ 800mm, length on request, roller pitch optional 130/195/260mm, motor power 750W, voltage 380V);

②Positioning unit: PU/H heavy-duty jacking positioning unit;

③Turning unit: PR/H Heavy duty rotary table.

All products support non-standard customization, which ensures precise matching with pallet size and load.

Question 3: In order to extend the service life of heavy-duty conveyor systems, what are the key points to focus on in daily use and maintenance?

Answer: 3 types of points to focus on:

①Load and operation control: overloading is strictly prohibited (maximum 4000kg for line body, 200kg for single set of roller), stacking is prohibited for bending/traversing units, and the appropriate conveying speed is selected according to the working conditions (avoiding prolonged operation at a high speed of more than 18m/min);

② wear and tear protection: when idle, close the conveyor section, reduce the weight of the pallet, regular cleaning of the drum and conveying media to avoid chemical corrosion;

③ Air source and component maintenance: guarantee the air source of pneumatic components for 4-6Bar dry filtered air, regularly check the lubrication status of the bevel gear drive, clean the impurities in the shield in a timely manner to ensure smooth transmission.