In the automotive electronics, logistics and warehousing in these areas that rely on automation, pallet conveying system is like the main artery of the production line - materials can not flow smoothly, high efficiency, all rely on it to support. And the beltPallet conveying systemsWith its excellent balance of smoothness, flexibility and cost, it has long been the meat and potatoes of short and medium distance transportation for small and medium-sized pallets. The core competitiveness of this system, in the final analysis, or look at the performance of the belt. Today to properly dismantle the two core belt conveyor systems suitable for the electronics industry, talk about their respective advantages and applicable scenarios, are real practical experience.

I. Toothed belt pallet conveyor system:

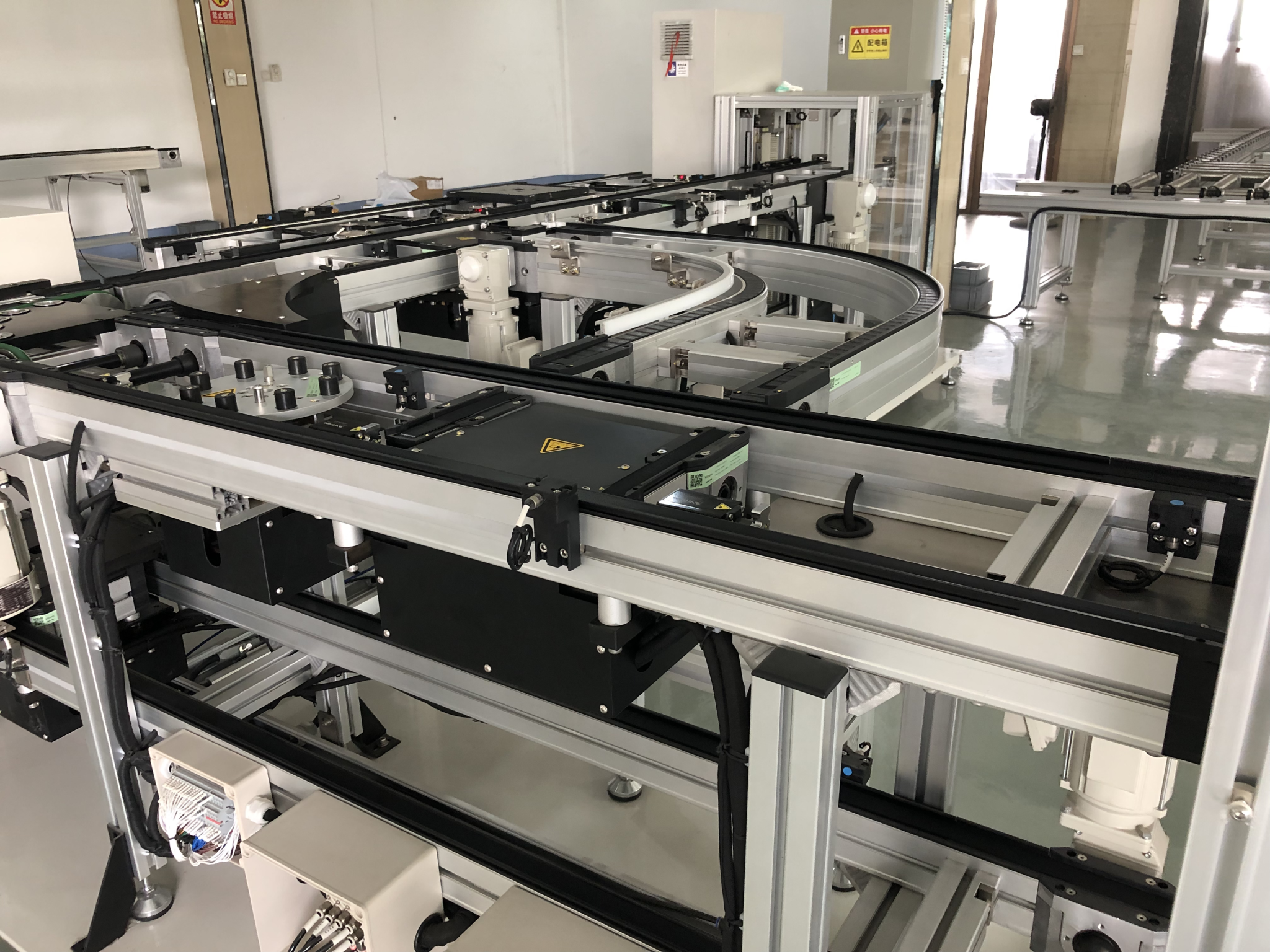

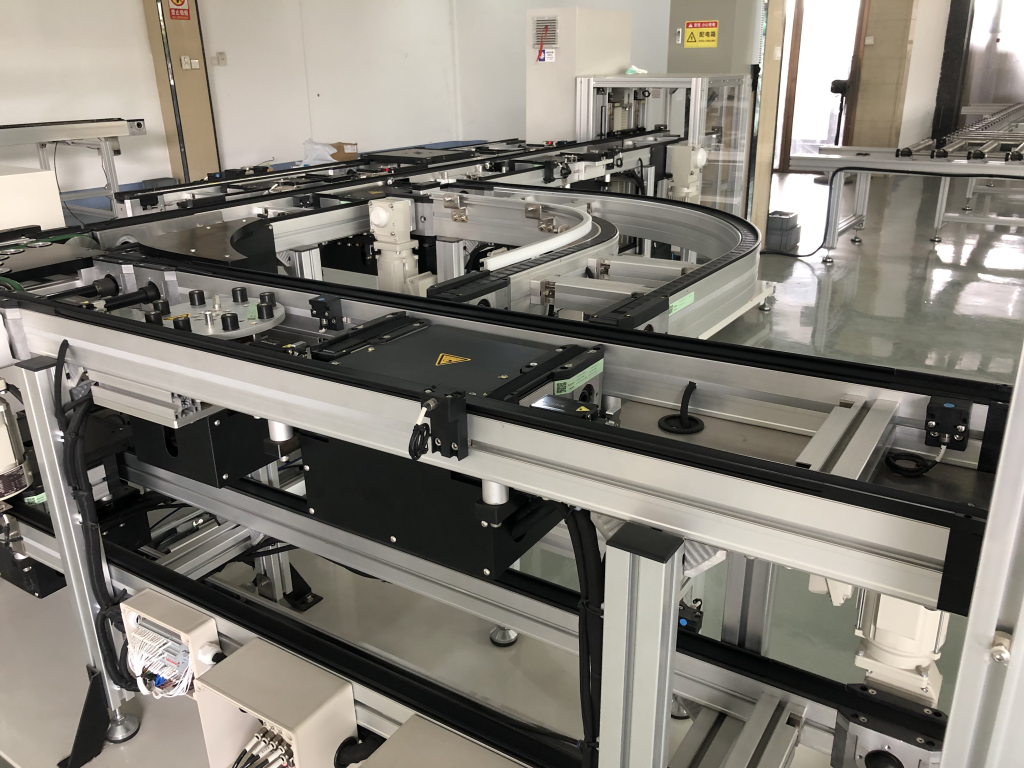

Toothed belt systems, also calledSynchronous belt conveyor lineIt consists of a workpiece pallet, longitudinal and transverse conveyor lines, supports, positioning system and controls, but the toothed belt design makes it particularly accurate in small to medium load scenarios.

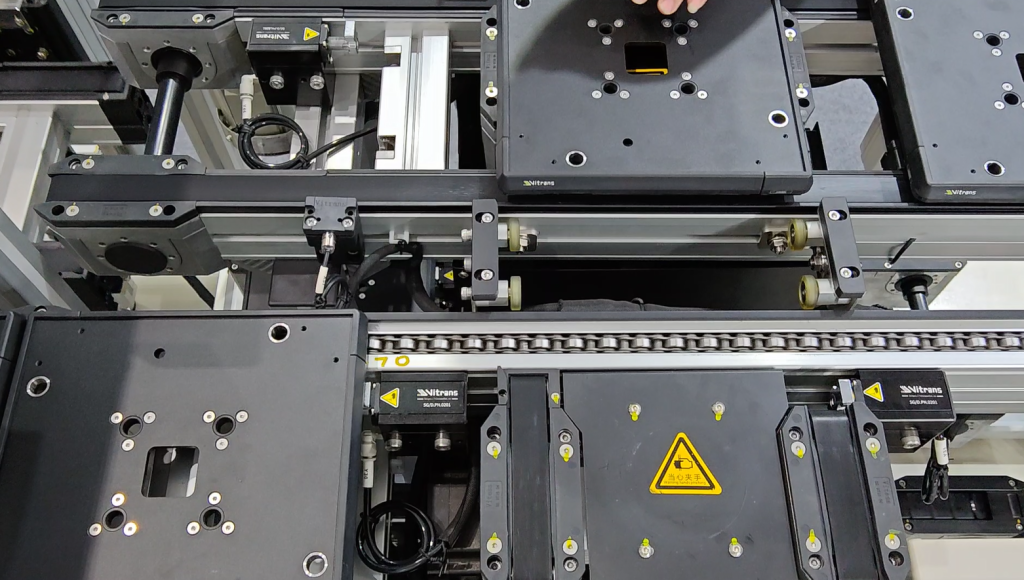

When it comes to performance, the three design highlights of the toothed belt are simply customized for the electronics industry. First, the double-sided cloth structure, can avoid the tray directly rubbing the belt's polyurethane layer, from the source to reduce the generation of powder and chips - to know, the production of electronic components on the cleanliness of the requirements of the extremely high, which can be too critical. Second, the steel core internal sandwich, not only to ensure the smoothness of the belt operation, tensile strength is also online, long-term use down is not easy to deformation. Third, permanent anti-static, production on the addition of anti-static materials, friction process will not produce static electricity, can be very good protection of sensitive electronic components.

Combined with practical applications, toothed belt system of single-section load limit is 60kg, single-section customized length of up to 6m, and pallet positioning accuracy of up to ± 0.05mm, so to speak, such as the electronic components of the inter-process transfer such as the need for precise control of the scene, choose it is right.

II. Sheet-based belt pallet conveyor system:

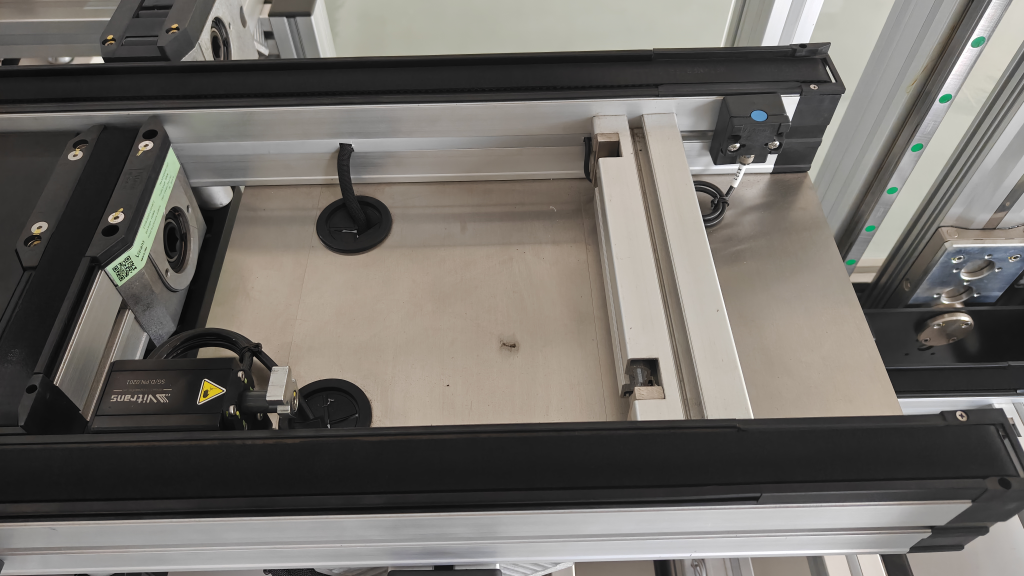

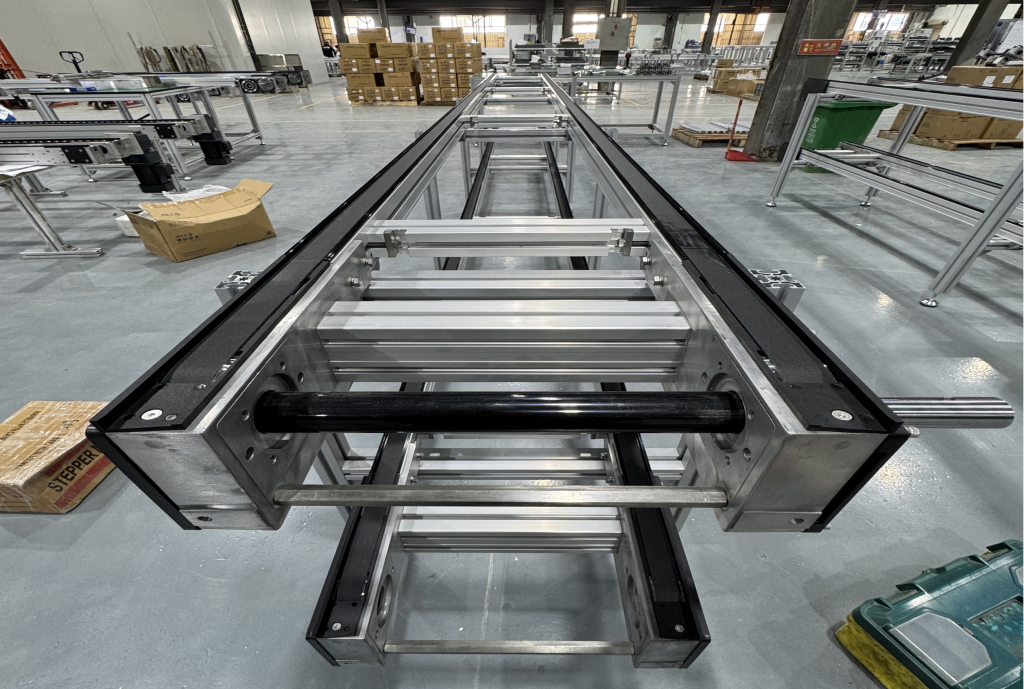

Chip-based tape-based systems are also called平belt conveyor, which also meets the basic conveying needs of the electronics industry, but the sheet-based beltstructural designThe belt is made of double-sided fiber fabric and a center-power sheet base. Its belt consists of double-sided fiber fabric and the center of the strong piece of grass-roots level: double-sided fiber fabric comes with permanent anti-static properties, abrasion resistance is also extremely strong, can cope with high-frequency pallet friction; center piece of grass-roots level of flexibility, even if it is a high-speed operation (maximum speed of 18m/min), but also to keep the belt smooth, will not let the pallet run off.

In practice, the advantages of the chip-based belt system are even more obvious. The upper load limit of a single segment can reach 250kg, which is almost 4 times more than that of toothed belt, and the customized length of a single segment can reach up to 30m, which can cover a longer conveying path. And it is suitable for a wide range of pallet specifications, 160 × 160mm to 800 × 800mm standard size can be customized, the bearing plate can also choose 5mm, 8mm, 12mm thick aluminum alloy or steel plate, the surface of the black anodic oxidation treatment, rust-resistant and durable. It can satisfy the scenarios that require heavy-duty and long-distance transportation, such as the transfer of semi-finished products of the whole electronic equipment.

Third, the conclusion: according to the needs of the selection, is the optimal solution

In fact, there is no absolute advantage and disadvantage of the two systems, the key is to look at your production needs - suitable for their own, is the most reliable. In terms of load capacity, toothed belt is suitable for small and medium-sized loads up to 60kg, while chip-based belt can easily carry heavy loads up to 250kg; if we talk about conveying distance, toothed belt is more suitable for short-distance transfer within 6m, while chip-based belt can cover up to 30m paths; in terms of precision, both systems can meet the requirements of3c electronics industryThe toothed belt type has a higher positioning accuracy, while the chip-based belt type is smoother at high speeds.

No matter it is toothed belt or sheet base belt system, it has the core advantages of permanent anti-static, high strength tensile and wear-resistant, which can fully adapt to the electronics industry's demand for clean, anti-static and high precision. In the automated production is increasingly dependent on the efficient flow of the present, choose a suitable belt conveyor system, equivalent to the production line installed a stable engine, can make the entire production process become more silky smooth.