Lithium industry as the core pillar of the new energy field, the automation, efficiency and stability of the production process directly affects the core competitiveness of enterprises. In the lithium industry.Pallet conveying systemsA range of benefits can be provided through automation applications and solutions. Below are some common automation applications and solutions:

Case 1: Automated Conveyor Solution for Electric Core Assembly

Conveyor line type:Modular Pallet Conveyor System

Response Program:To meet the high requirements of battery core assembly on beat and precision, it adopts fully automated modular design, which can be flexibly adjusted according to the enterprise's production capacity planning, and is suitable for the different production requirements of 24-50PPM of a single line, and there is no need for manual intervention in the whole conveying process.

Application effects:Realize the automation of the battery core assembly process, not only to ensure the assembly accuracy and product consistency, but also significantly improve production efficiency, suitable for different sizes of enterprise capacity expansion needs, the equipment stable operation performance is good.

Case 2: Multi-size Battery Assembly Conveyor Program

Conveyor line type:customizationPallet conveying systems

Response Program:To meet the needs of battery assembly for multi-specification battery cells, we optimize the design of tray structure, which is compatible with all kinds of battery cells with width 140-180mm, length 91-210mm and thickness 20-80mm, and with fully automated assembly process to reduce the manual transferring process.

Application effects:Successfully solved the problem of adapting multi-specification battery cell production, single line beat covering 5-40PPM, effectively reducing the risk of error caused by manual operation, and improving the stability and production flexibility of the assembly process.

Case 3: Energy storage battery PACK test line conveyor program

Conveyor line type:Accumulation roller conveyor line

Response Program:Focusing on the heavy-duty characteristics of energy storage battery PACK, we designed a heavy-duty conveyor line with a single pallet load of 450KG, integrating 21 core stations for heavy-duty jacking positioning, jacking traverse, jacking rotation, etc., to realize the full automation of the testing process.

Application effects:It perfectly matches the heavy-duty transportation needs of energy storage battery PACK, covering the whole testing process, with smooth and lag-free workstation connection, which not only improves the testing efficiency, but also guarantees the accuracy of the testing data and meets the needs of large-scale testing.

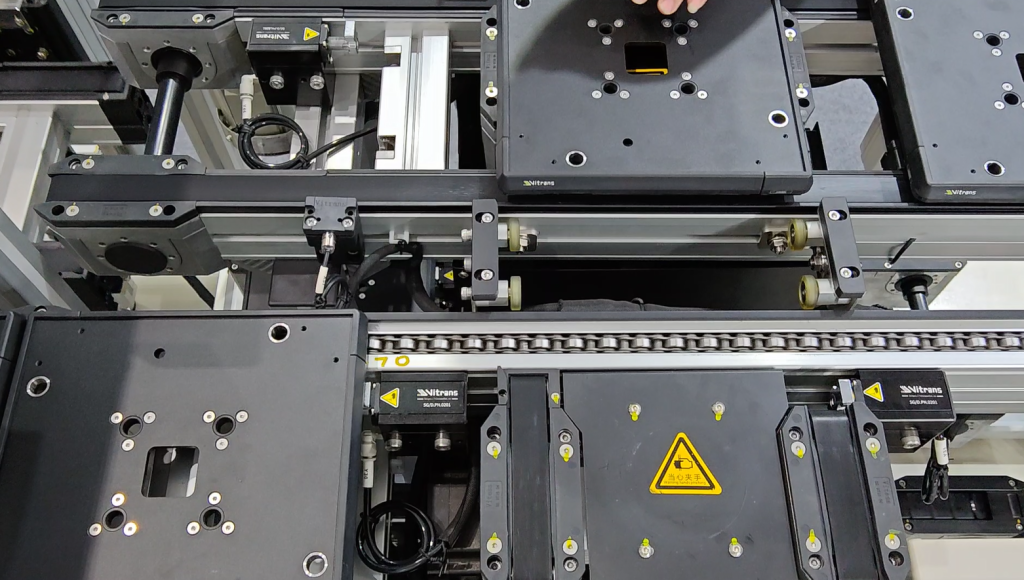

Case 4: Battery module assembly and testing integration program

Conveyor line type:heavy load (on a truck)doubled speed chain(12B) Pallet conveyor line

Response Program:Adopting heavy-duty speed chain structure, single pallet load 300KG, integrating 14 sets of non-standard devices (including jacking positioning, lifting machine, jacking rotation, etc.), realizing coherent operation of assembling and testing process through modular combination, and optimizing the design of upper and lower floors to save space.

Application effects:The line runs stably and reliably, completes the integrated connection of battery module assembly and testing, the upper and lower layout effectively reduces the workshop floor space, adapts to the spatial planning needs of large-scale production, and the integrated design of non-standard devices improves the process adaptability.

summarize

Wei Chuang AutomationThe reason why the tray conveying line can adapt to the lithium industry multi-scene demand, the core stems from three major advantages:

First, standardized production to ensure quality, equipment can be stable operation for more than 3 years;

The second is the ability to deliver quickly, with customized deliveries in 2-4 weeks;

The third is cost-effective, compared with imported brands with prices lower than 30% or more, while equipped with a 24-hour after-sales response mechanism.

Under the trend of pursuing efficient, stable and flexible production in the lithium industry, the pallet conveyor line, through customized solutions, is becoming the enterprisereduce costs and increase efficiencyThe key equipment to enhance competitiveness and provide a solid delivery guarantee for the high-quality development of the industry.