In the automated production plant.Pallet conveying lineIs an important role in the material flow process - the right choice, the entire production line can be smooth, efficiency pull full; if you choose the wrong, as small as frequent jamming, equipment overload damage, will only make the rhythm of production into a mess. For the first selection of enterprises, do not blindly chasing high-end, the core is to meet the actual needs.(reddish jade)Combined with years of experience in contact with customers of this type of selection needs, organized a few key points of attention to help you step on the pit, less detour.

1,Material size and weight are the basis

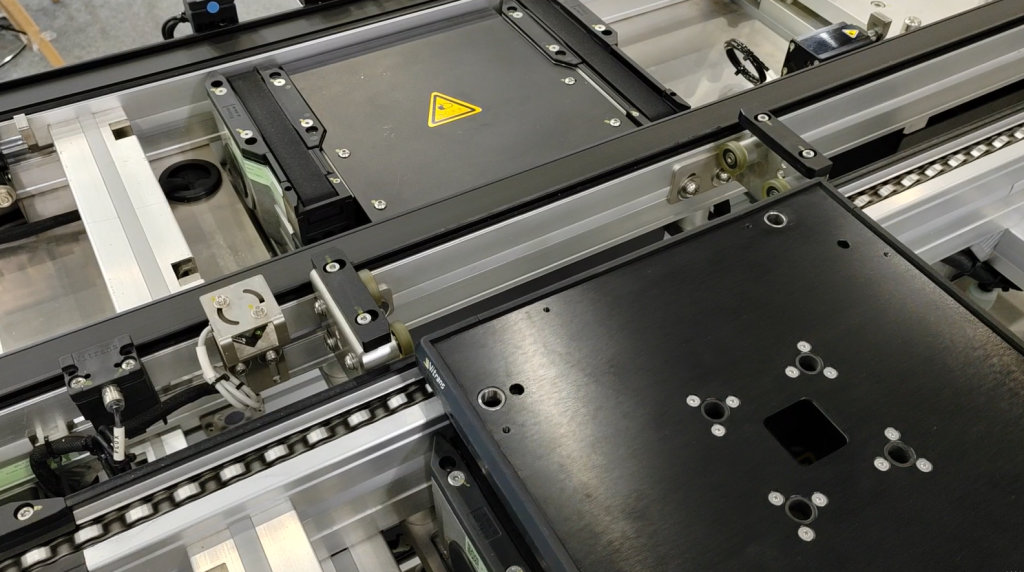

The first step in the selection process is to understand the material - size and weight are the basis. The total weight of the material and fixture is directly determined by the type of pallet and conveyor line: light load (≤ 120kg), then choose WA2 pallet with BC2 or FC2 conveyor line is enough; heavy load (≤ 240kg) have to choose WE2 pallet with AC2 or PC2 conveyor line, if the total weight of more than 2,200kg of heavy-duty scenarios, the AC2/H model will be more appropriate.

Material size should be matched with the pallet specifications, conventional 160 × 160mm to 800 × 800mm are readily available, special size can also be customized. Here is a small reminder: do not let the material partial load, as far as possible in the center of the pallet, the center of gravity height is best not more than half of the width of the pallet, otherwise not only conveyor is not stable, but also may shorten the life of the equipment.

2,Distance, speed and positioning should be precise

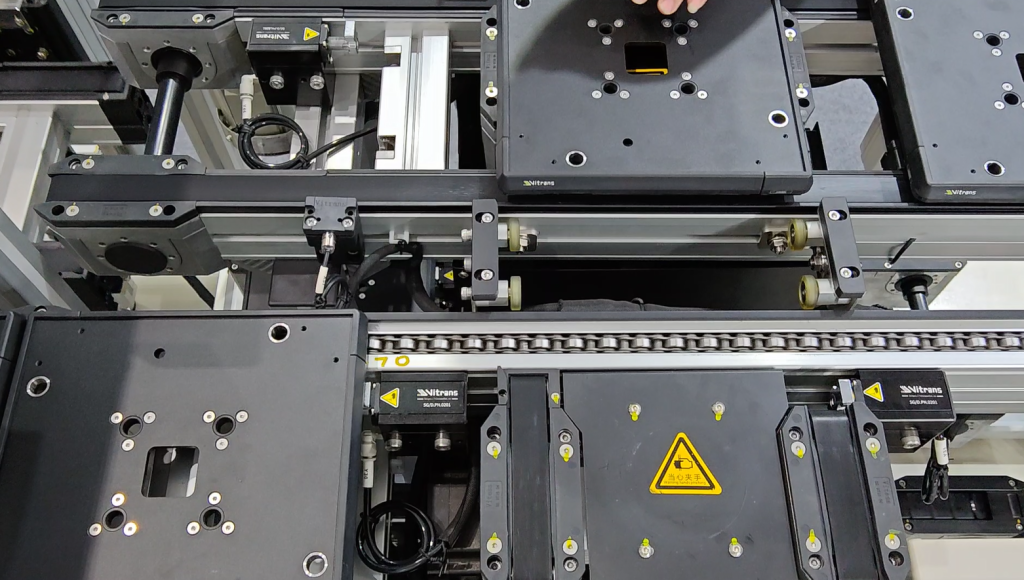

And then the conveying needs to be clear - distance, speed, positioning, none of them can be ambiguous. Short-distance conveying (generally ≤ 6 meters), give priority to BC2 or PC2 conveying line, toothed belt, overhead chain design, especially suitable for clean, light load scenarios; if the distance is more than 6 meters, FC2 or AC2 conveying line is more reliable, flat belts or stacked roller chain can be stable to achieve continuous conveying.

Conveying speed according to the production beat on the line, the conventional 0-18m/min can basically meet most of the needs, want to adjust the speed, with a frequency converter is good. If the process requires precise positioning (such as automated assembly), then you have to choose the conveyor line with PX pin positioning (± 0.1mm accuracy) or PU jacking positioning unit, otherwise the positioning deviation may affect product quality.

3,Production environment: details determine equipment life

The production environment must also be adapted, these details often determine how long the equipment can be used. Ordinary workshop should pay attention to the working temperature, +5 ~ +40 ℃ is a more appropriate range, beyond this interval, equipmentcarrying capacityIt may decline; wet environment has to choose the rust-proof treatment of parts, high-temperature environment needs to be customized high-temperature-resistant materials.

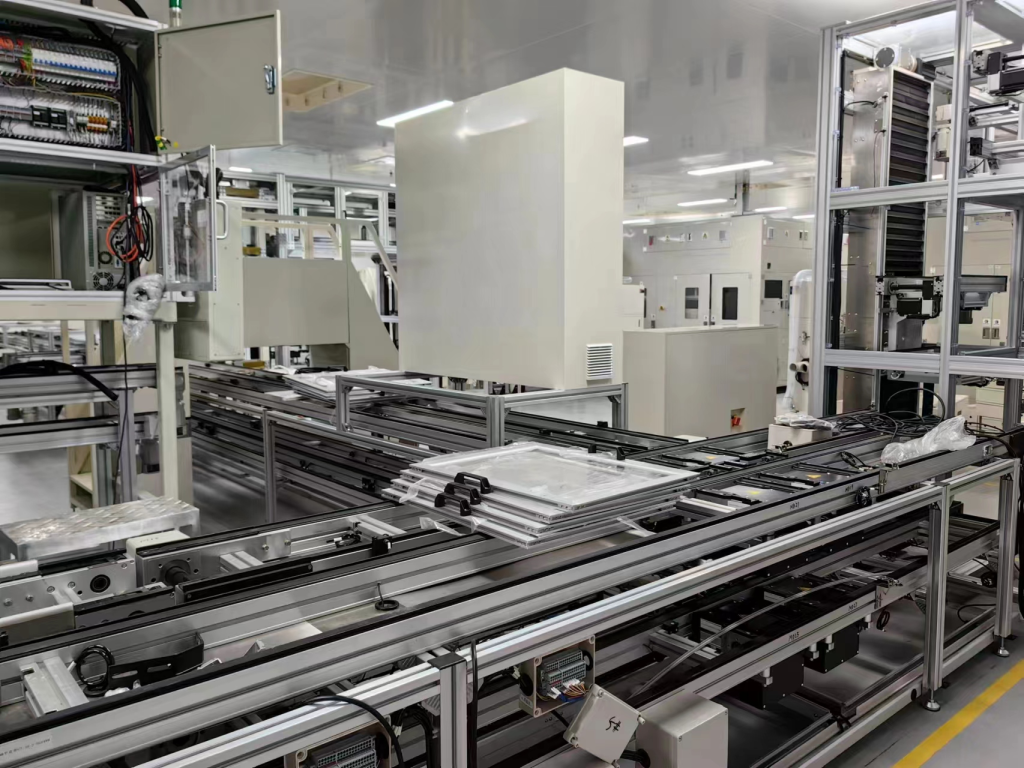

If in the electronics, lithium batteries, such as high cleanliness requirements of the workshop, the priority of choiceOverhead Chain Conveyor LineOr flat belt conveyor line, WA2, WE2 pallet itself has anti-static design, can avoid generating dust and static electricity. In addition, try to keep the equipment away from chips and chemicals, which can reduce unnecessary wear and tear.

4,Adaptation of sites and processes

How do you match the site and the production process? Layout planning must follow the actual situation. Straight conveying, the conventional conveyor line can handle; need to turn (90 ° or 180 °), take a KV or CV series of curved units on the line; want to achieve multi-layer conveyor, LP / B synchronous belt elevator or LP / S screw elevator is a good choice, lifting speed of up to 500mm / s. Layout should also be considered when the pallet cycle, horizontal or vertical circulation must be combined with the size of the site, and at the same time, reserve space for maintenance to avoid the trouble of adjusting later. Maintenance space, so as to avoid the trouble of later adjustment.

5,Focus on compatibility and customization

There's also compatibility and customization, which are easily overlooked but important. PrioritizeModular Pallet ConveyorIt is convenient to expand or adjust the equipment later. Pay attention to the matching of conveying medium and pallet: belt and toothed belt should be matched with WA2 pallet with PA wear-resistant pads, and roller chain and overhead chain should be matched with WE2 pallet with PE wear-resistant pads, which will only increase the abrasion if they are matched wrongly.

There are special needs (such as non-standard size, special voltage, high-precision jacking), then, in advance to communicate with the manufacturer on the line, such as Vitrans brand support customization, but be sure to make the technical parameters clear, to avoid late adaptation problems.

6,Inspection of equipment quality and after-sales

Finally, don't forget, the quality of equipment and manufacturers after-sales is also very important. The first selection don't just look at the price, have to choose the market proven brand, focusing on the motor, conveying media, the durability of these core components. At the same time to confirm the manufacturer's after-sales service, such as there is no installation guidance, parts supply and not timely - perfect after-sales can reduce downtime, so that production is less affected.

indeedPallet conveying lineThe core of selection is adaptation, puttingMaterial CharacteristicsThe combination of these points, production needs, site environment and judgment, you can choose a cost-effective equipment. If there are still questions about the parameters with, you may want to look at the selection manual provided by the brand, or directly consult with professional and technical personnel.