customizablePallet conveying lineIn the end, choose roller or chain? Many customers just contact will mutter - look at all with pallet conveying, with the difference is not small. In fact, roller conveyor line and chain conveyor line in the pallet conveying applications have their own advantages, how to choose depends on the user's specific needs, there is no absolute “who is better”. Choose the right not to choose expensive, in the end, what kind of situation should choose roller, what kind of situation to choose chain?

You can take a look at the following comparative analysis based on common application scenarios:

One,Two types of pallet conveyor lines, in the end therewhich ones?Not the same?

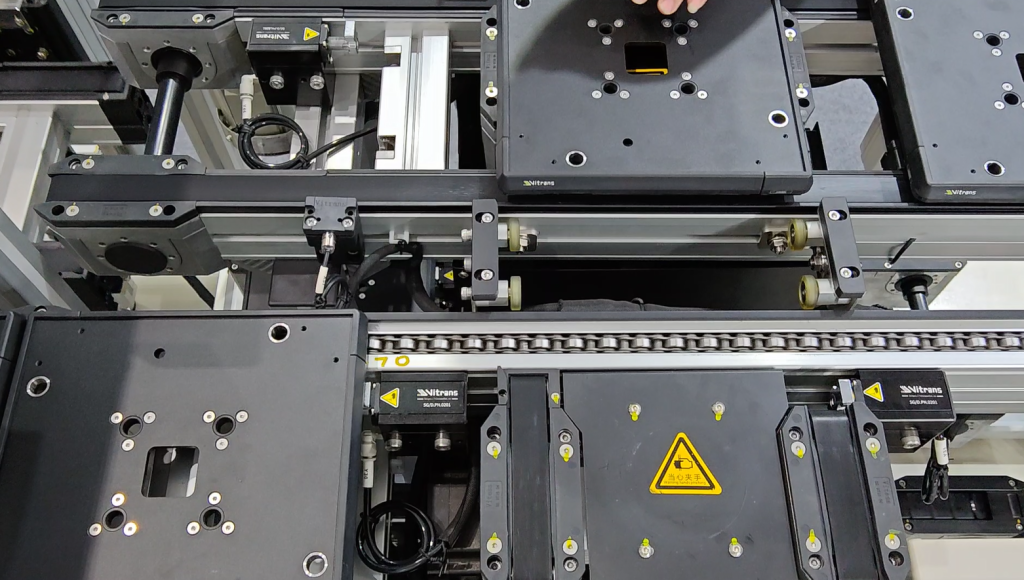

1,Roller conveyor line

As the name suggests.platen lineIs to rely on the rotation of the rows of rollers, carrying the pallet forward, especially suitable for those bottom surface regular, hard material pallets. It runs steadily, the noise is also small, usually maintenance is not a problem, the impact on the pallet is minimal. Generally speaking, light to medium-sized loads of short-distance transportation, with it right, especially in sorting, warehousing such scenes, the cost is often very high.

Advantageous features:The core advantage is definitely its flexibility and process adaptability. The modular design, put together like building blocks, can easily form a complex conveyor system. What's more, it (Accumulation roller conveyor line) The ability to pause, accumulate and release material directly on the conveyor line is just what is needed for production lines that require buffering operations or assembly operations. Of course, it prefers products with flat bottoms - whether it's pallets, crates or cartons - and conveys them smoothly.

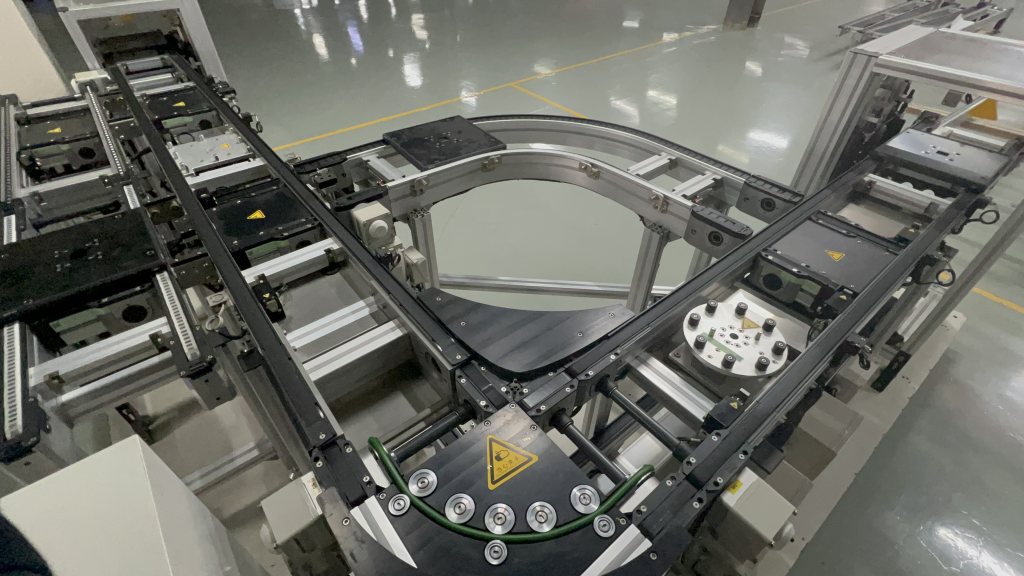

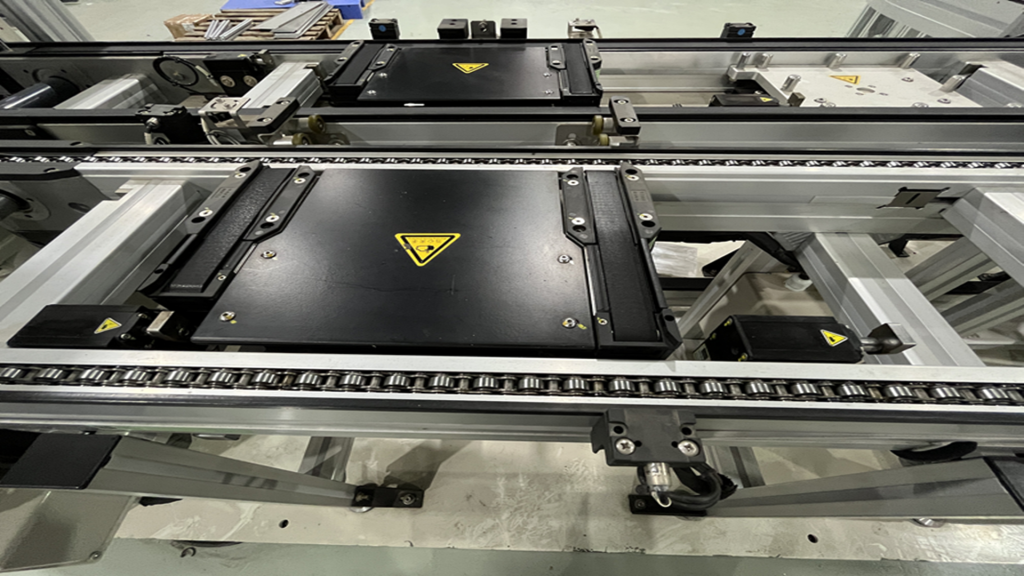

2,Chain conveyor line

Unlike the roller type, this kind of conveyor line relies on the chain as the core driving part, which is born with the gene of “load-bearing”, and its carrying capacity is not generally strong, so it can deal with heavy pallets or loads with irregular shapes, and can achieve stable conveying. It is especially suitable for those who need to start and stop frequently, accurate docking workstation operations, such as and jacking lift with the work of the scene, such as assembly lines or heavy industry workshop, you can often see its figure. However, there is a point to mention, it runs up the noise, maybe a little bigger than the roller type.

Advantageous features:Its core advantage lies in the simple structure, durable and stable. The driving method is straight, and there are not so many mechanical parts, so there are fewer failure points, and maintenance is also less worrying in the later stage. If you need a long distance, high strength, uninterrupted linear transportation, such as the pallet from the workshop this end, stable transportation to the other end, then its economy and stability, will make you feel that the right choice.

Two,How do I choose?弄These four questions are enough.

After understanding the performance characteristics of the two types of conveyor lines, it is time to practice the link. Put it this way, you want to quickly finalize the style, we just need to figure out the following four key questions, the answer is basically on the surface.

1,How much do your palletized goods really weigh?

If it is a medium-sized load, and you still want to pursue the experience of stable operation and low noise, then the drum type is most likely your choice; but if you want to transport heavy, large-volume goods, such as large machinery parts and piles of raw materials, then the chain type (doubled speed chainconveying line) of strong load bearing and sturdy performance to carry the job.

2,Is the pacing and control of the process demanding?

If your production line requires frequent starts and stops, precise positioning, or have to let the pallet queue accumulation - for example, assembly line, the pallet has to stop at different stations, etc., then the roller type (especially motorized pulley models) of the control precision, can make the whole process a lot of silky smooth; but if it is a continuous unidirectional, the beat of the steady high-intensity conveying, such as But if it is a continuous unidirectional, steady beat high-intensity transportation, for example, from this end of the workshop to the end of the uninterrupted transportation of pallets, the durability and reliability of the chain type, will be more people's heart.

3,The working environment isnothingWhat kind?

If you are in the food, medicine, electronics, such as the requirements of hygiene and cleanliness of the industry, or near the workstation for fear of noise disturbance, then choose the stainless steel roller line that meets the cleanliness standards, it is certainly right; but if it is dusty, humid, high temperature, or even full of oil in the heavy industrial workshop - such as casting, forging yards, the chain type of resistance to manufacturing performance, in this environment will be more suitable.

4,Is the transportation path complex?

For straight lines or layouts with a little bend, roller lines can be easily realized, and several lines can be put together to form a complex system; however, if you want to engage in frequent 90-degree turns, diversion and merging of such operations, the chain line may have to be coupled with a chain carousel and other specialized equipment to be able to do so. But then again, the chain line is not only straight line, like the speed chain design style, can be used in the assembly line of the metronomic operation, as well as to achieve the accumulation and release function.