Electronic components are piled up in the material area waiting to be put on line, heavy parts get stuck in the conveyor, and once the sorting line is congested, the entire line is forced to shut down. ......

In practice, thematerial handlingInconsistency is often a key factor in efficiency and cost. From precision parts weighing a few grams to hundreds of kilograms of mechanical parts; from standard cartons to workpieces of different shapes, every unstable link in material transportation is magnified into efficiency loss. For manufacturing companies, a stable and scalable conveying system is an important foundation to ensure continuous production operation. Wei Chuang'sPallet conveying systemsIt is designed as a systematic solution for material handling in industrial sites.

One,modular design–Adapting to changing production needs

The needs of a manufacturing site are not static. Conveyor routes may need to be lengthened and diverted, and the layout of workstations may change as the production line adjusts.

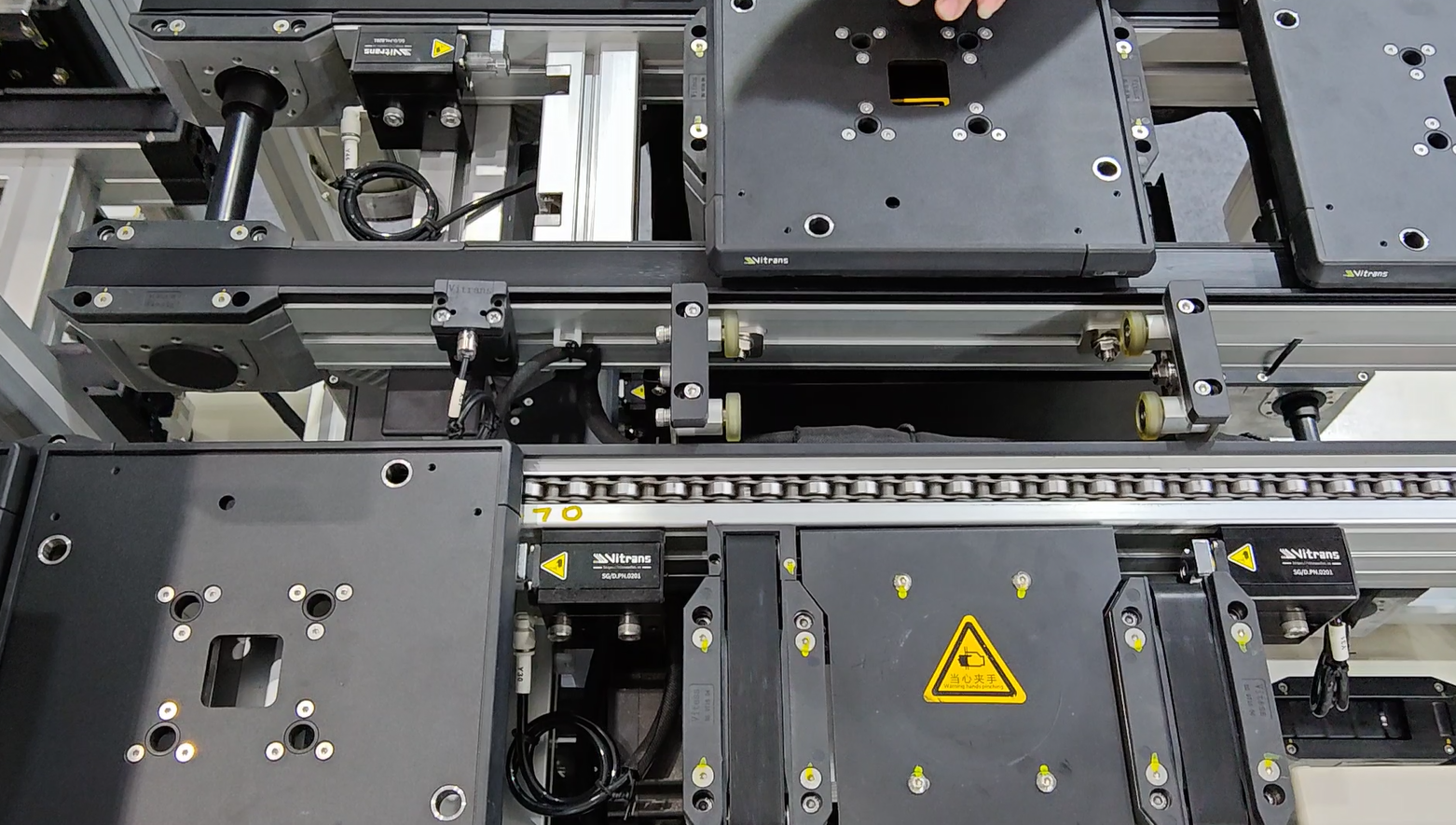

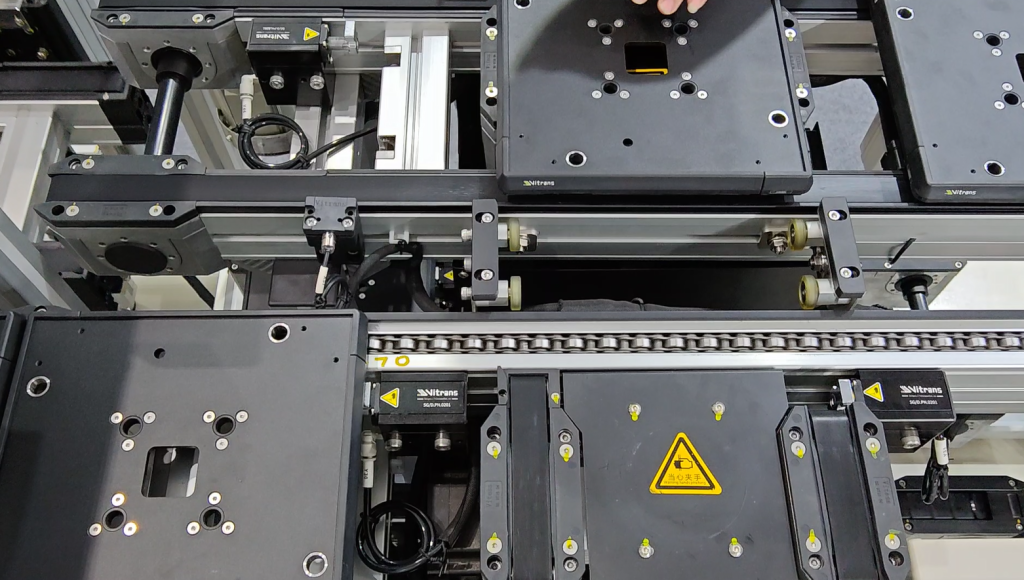

Pallet conveying lineAdopting modularized design, it can be flexibly configured according to the actual demand, avoiding the problem that a line is only suitable for one kind of use.

The system components can be freely combined and are compatible for use with pallet conveyor lines and related modular equipment. It can be operated either as a stand-alone conveyor line or integrated into existing production systems, and peripheral structures such as cabinets and shrouds can be extended as required.

This modular approach allows companies to adjust or expand production lines without the need to replace equipment as a whole, reducing duplication of investment and transformation costs, and is suitable for small and medium-sized production lines, as well as for large factories with complex structures.

Two,Stable operation - reduced maintenance and downtime costs

Maintenance costs and unplanned downtime are often hidden costs that are easily overlooked throughout the equipment lifecycle.

Pallet conveying lineThe use of wear-resistant materials and stabilizedstructural designIt operates reliably and has a low routine maintenance workload.

Stable operating conditions help reduce the risk of downtime caused by faults. At the same time, by replacing manual handling with automated conveying, it also reduces labor input, improves overall logistics efficiency, and creates a more controllable cost structure in actual production.

Three,Clear structure with core components in their respective roles

Pallet conveying lineThe structural design is simple and clear, and the key components work together to ensure a smooth and reliable conveying process:

■ Basic framework: as the system's load-bearing structure, to ensure overall rigidity and operational stability

■ Return pulleys: Arranged at both ends of the conveyor line, they are used to change the running direction of the belt and optimize the conveying path.

■ Sliding plates: provide a smooth and level running surface for the belt, reducing friction and wear.

■ Flat conveyor belts / synchronous conveyor belts: Selected according to different materials and working conditions to ensure a smooth conveying process.

■ Transmission components: provide stable power to the system, guaranteeing conveyor speed and beat consistency.

This standardized, configurable component system is easy to design, install and adjust later.

Four,Configuration is clear and the program is more relevant to the actual application

In response to the concerns about the long cycle of customized equipment and the difficulty in predicting the results, WeiChuang manufacturers provide mature configuration tools and technical support.

Enterprises only need to provide conveying length, width, material weight and other basic parameters.(reddish jade)The technician can then develop a suitable delivery solution for the specific application scenario.

Whether it is a single production line with compact space or a complex logistics system; whether it is the continuous conveying of light workpieces or the stable transfer of heavy components, Wei Chuang's pallet conveyor lines can be customized.

Through more stable transportation and more flexible expansion methods, it helps enterprises reduce logistics bottlenecks and make production beats more controllable.

In real-world industrial applications, customized pallet conveyor lines are a material handling solution that deserves long-term consideration.