In the industrial scene where heavy work piles up in automobile manufacturing, heavy equipment assembly, and large workpiece machining, thePallet conveying systemsJust like the silent power of the industrial artery - several tons of heavy workpiece pallets, relying on it to flow steadily, holding up the entire production rhythm. Unlike the belt conveyor for light and small parts, the core competitiveness of heavy-duty conveying is in fact modular design, no need to make a big effort to transform, can be combined through different modules to deal with the whole process from linear conveying to steering, positioning, shunting needs. Today to dismantle, a reliable heavy-duty conveying system, in fact, what key roles are hidden.

I. Core Conveyor Module: The Backbone of Heavy Duty Transportation

If the heavy-duty conveying system is compared to a complete transportation network, the core conveying module is the main road in the network, responsible for the most basic bearing and conveying, which is the bottom of the whole system.

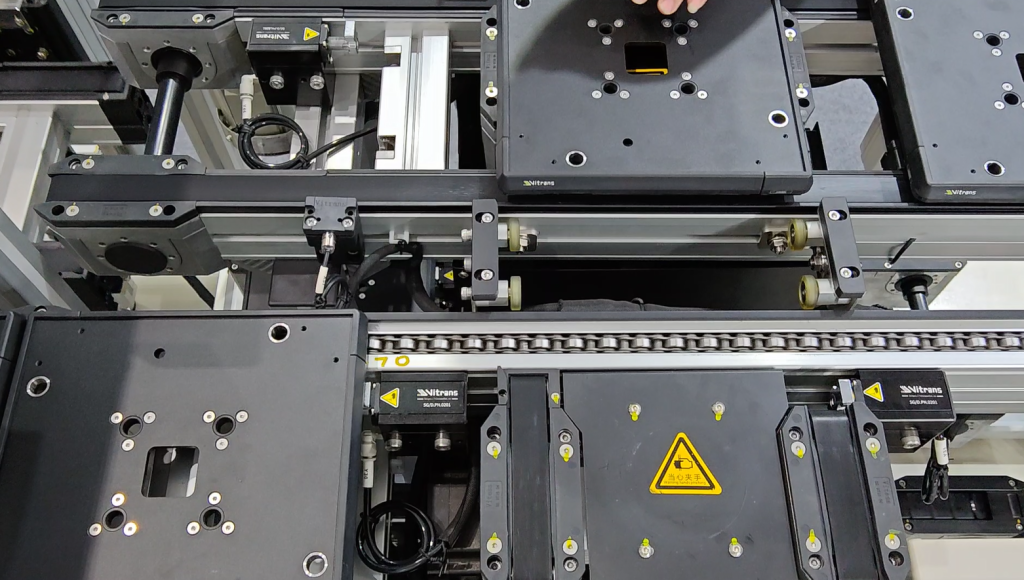

accumulativeroller conveyorIt is definitely the core backbone here, specializing in heavy-duty pallets of 4 tons and above. It uses stainless steel rollers as conveying medium, with bevel gear spindle drive - you may not believe it, running almost no noise, maintenance is also worry-free, but also manually adjust the friction adapted to different workpieces. Line body is made of high-strength aluminum profiles, the width can be selected between 300-1200mm, the length from 1000mm to 6000mm can be adapted to support forward and reverse not to mention, but also allows the workpiece stacking storage, the motor can also be selected according to the needs of Sumitomo, Seiken, these reliable brands, is a heavy-duty conveying the standard models.

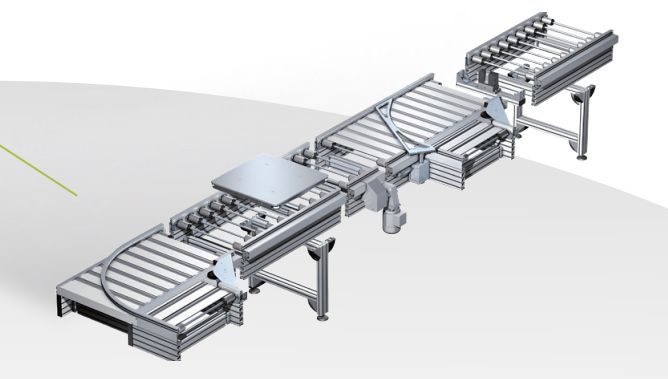

When you have two perpendicular conveyor lines, you can't let the pallets take the long way around, can you? This is where the Heavy Duty Traverse Module (ET2/H) comes in, which is equivalent to building a direct bridge between the two lines. It can move the pallet from one line to the other smoothly, realize 90° direction switching, can carry 1.5kg/cm load per unit length, and can adapt to a maximum of 1200*1200mm pallet. Directly driven by a three-phase motor, it also supports reverse operation, no matter the main line to branch line, or branch line back to the main line, it can be articulated smoothly.

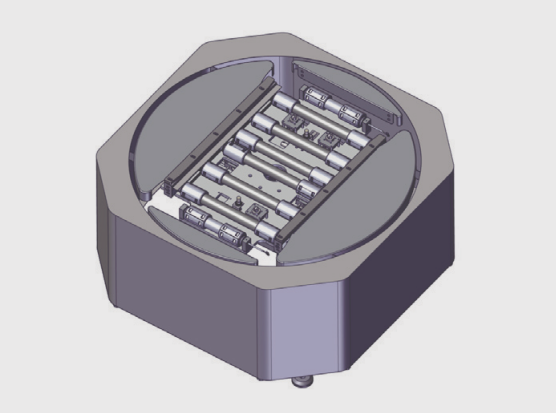

There is also the heavy duty rotary table (PR/H), which is the directional regulator in circular lines or layouts where there is no room for curves. Controlled by a servo drive, it can turn a pallet 90°, 180°, or even 270° without changing the front or rear orientation of the pallet, ensuring that the workpieces are always oriented correctly during the multi-process flow. It can carry a maximum load of 400 kg, turn 90 ° is only 4 seconds, compact structure does not take up space, for the flexible production line, it is just a module.

Second, auxiliary function module: the key step to deal with precise control

The core module is responsible for moving, the auxiliary function module focuses on accurate transportation, distribution, especially processing, assembly, testing, which requires accurate positioning of the workstation, can not do without them.

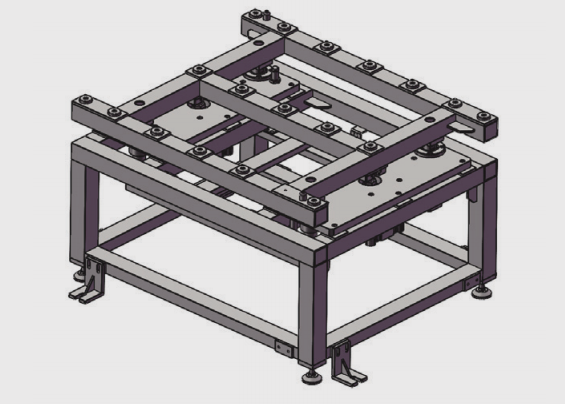

When the pallet to the processing or testing station, heavy-duty lifting positioning unit (PU / H) is the accurate centering pill - first stable blocking stop, and then rely on the double cylinders slowly lifting the pallet off the conveyor surface of 5 mm, repeatable positioning accuracy of ± 0.3 mm, simply more accurate than a ruler. It can carry a maximum load of 400kg, from 480mm to 1200mm pallet can be adapted, and horizontal blocker used in conjunction to ensure that the workpiece does not move when machining, the accuracy of this piece of the pinch to death.

In a multi-station flexible production line, the diverter (JU) acts as a traffic conductor, accurately distributing pallets from the main line to the different branch line stations. It is ready-to-usemodular componentIt can be installed directly on any side of the bevel gear spindle, controlled by pneumatic cylinder, and can divert up to 300kg of workpieces (conveying speed 9m/min), and can be adapted to the diverting needs of multiple work processes without complicated modifications.

There are also horizontal blockers, which are considered as safety gates in heavy-duty conveying, specialized in blocking and stopping the stacked pallets at the designated position. Driven by a cylinder with a bore of 50mm, it can block up to 550kg of heavy loads, can withstand a working pressure of 0.7MPa, and can work stably in environments ranging from -10°C to 60°C. When the pressure is released, it can be closed and stopped by a spring. When the pressure is released, the spring closes the stop, the structure is simple and reliable, often used in conjunction with the jacking and positioning unit to avoid misalignment of the pallet.

Third, the selection of small tips: according to the need to match the cost-effective

heavy load (on a truck)Modular Pallet ConveyorNo need to blindly chase high parameters, the core of the two words: fit. Let's put it this way, if the load exceeds 4 tons, bevel gear accumulation roller conveyor line is correct; pallet size is special, non-standard customization can also be dealt with; if the process requires accurate positioning, then the jacking positioning unit can be arranged; multi-branch line shunt, the shunt is the need; if the ring layout, the rotary table is indispensable.

In addition, the environment must also be taken into account - wet or corrosive places, give priority to stainless steel components; high-frequency use of the scene, you have to pick the maintenance of the drive motor is convenient. In the end, suitable for their own production rhythm, is the most cost-effective choice.

Modularized combination: flexible adaptation to the whole scene

From a single linear conveyor to a complete process of conveying-steering-positioning-diverting, the advantage of heavy-duty conveying is actually the flexible combination of modules. These modules are like a set of battle-tested industrial building blocks, which can be used individually to meet basic needs, and combined to adapt to complex processes - and can be followed up from planning, installation to maintenance in a one-stop manner, saving a lot of trouble.

In the end, reloadingModular Pallet ConveyorThe key is not to be able to carry heavy loads, but to carry them stably and use them effectively. The above modules cover the core requirements and key nodes of heavy-duty transportation, and it is their tacit cooperation that makes the heavy-duty flow in industrial production both efficient and reliable. If your production scenario has special needs, these modules can also be customized non-standard, the real on-demand configuration, so that heavy-duty transport to accurately match your production rhythm.