In the production workshops of electronic manufacturing, automotive parts, new energy and other industries, thePallet conveying systemsIt is the core equipment to ensure the efficient operation of the assembly line. Many enterprises in the selection of models, often by the load limit, conveying distance, the use of the environment and other issues are difficult - the space is narrow which to choose? What to pay attention to long-distance transportation? How to match the heavy load scene? As a source manufacturer focusing on modular pallet conveying system for 10 years, theWei Chuang AutomationSort out the 4 types of core pallet conveying line, with straightforward parameters and practical scenarios, to help you quickly choose the right adapted equipment!

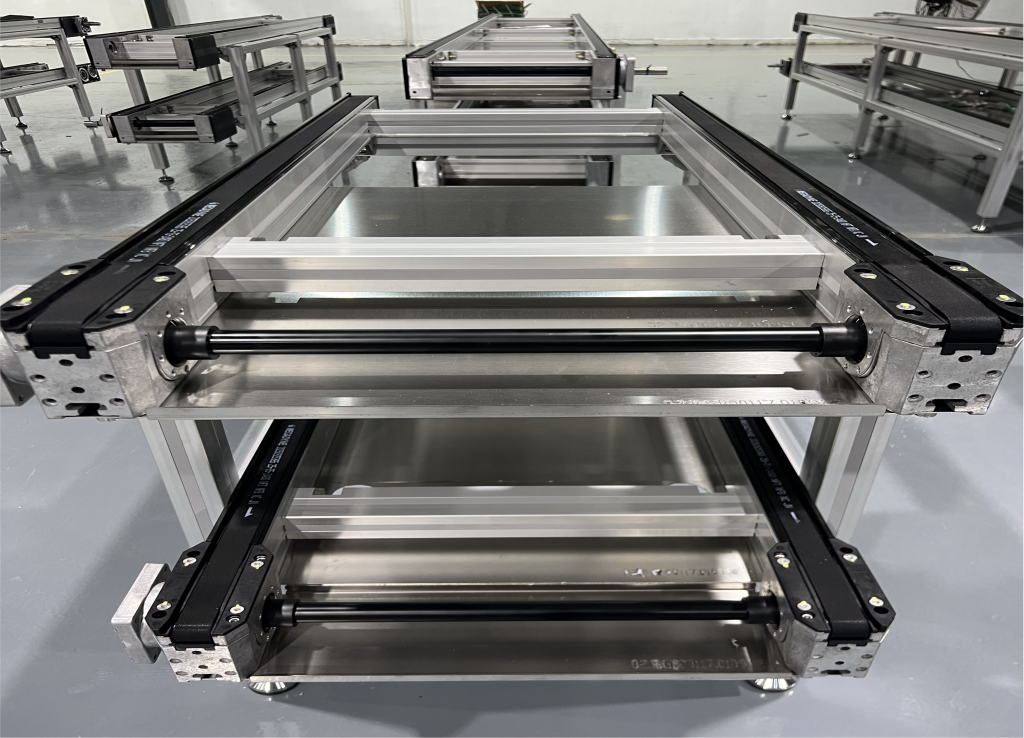

One,Synchronous belt conveyor line

As a flexitarian in a palletized conveyor system.Synchronous belt conveyor lineDesigned for space-constrained, light-duty conveying scenarios, the core advantages focus on compactness and stability.

- Core Parameters:The maximum load of single section is 60kg, and the longest conveying length of single section is not more than 6m. It is driven by servo motor and supports forward and reverse running and stacking operation;

- Applicable Scenarios:Light-load products such as automotive electronics, 3C electronics, etc. are conveyed, especially suitable for production lines with compact workshop layout and flexible route planning;

- Product Highlights:Modular design is easy to install and adjust, equipped with special polyamide wear pads to meet the requirements of anti-static, low running noise, positioning accuracy can assist in improving production stability.

Two,Flat Belt Conveyor Line

If the production requirements are for long distance, continuous transportation.Flat Belt Conveyor LineIt is undoubtedly a cost-effective choice, balancing efficiency and practicality.

- Core Parameters:The maximum load of a single section is 250kg, and the longest conveying length can be up to 30m. It is driven by an independent three-phase geared motor with a load limit of 1kg/cm per unit length;

- Applicable Scenarios:Long-distance light-load conveying in dry and clean environment, can be matched with workbench and light stand to form assembly line, suitable for electronic instrument assembly, food packaging and other processes;

- Product Highlights:Support stacking cache operation, modular components for easy post maintenance and route modification, the belt material can be selected from rubber, PVC, PU, etc. to meet the needs of different industries, and comply with anti-static standards.

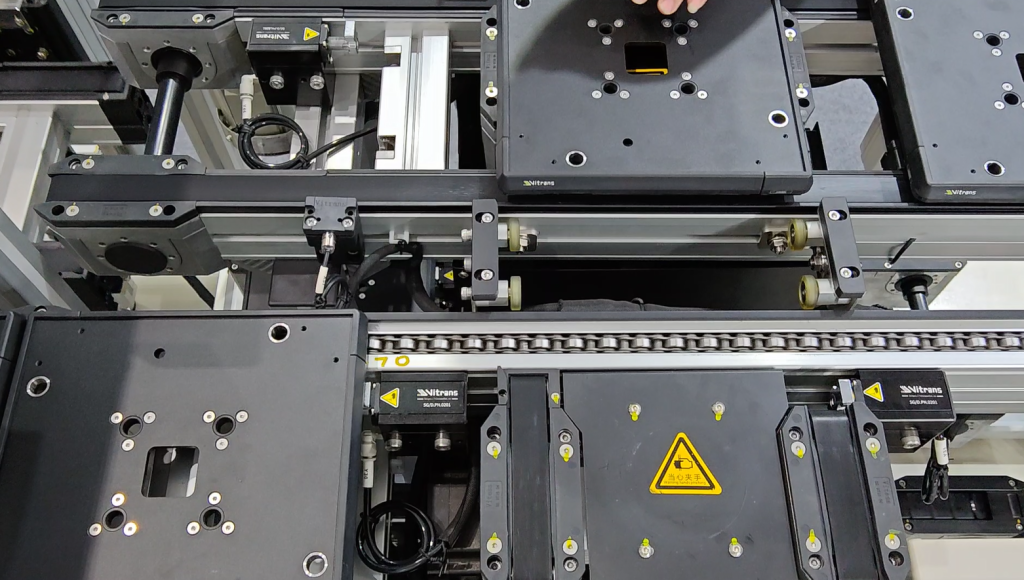

Three,doubled speed chainconveying line

Faced with the demands of heavy-duty, high-tempo production, theSpeed Chain Conveyor Lineleveragecarrying capacityBecome the core choice for industrial scenarios.

- Core Parameters:Maximum load is 2200kg under light load condition, and up to 4000kg under heavy load condition. Maximum conveying length of single section is 30m, and stacked roller chain (nylon or steel) is used as conveying medium;

- Applicable Scenarios:Automotive parts, new energy batteries and other heavy-duty product transportation, can adapt to a certain degree of harsh environments, especially suitable for the production of assembly lines with high requirements for the production beat;

- Product Highlights:Equipped with modular chain auto-tensioning device, it can compensate for the size change of chain wear and temperature, reduce noise and avoid tampering; it supports stacking operation and the modular design is convenient for non-standard customization to meet the articulation needs of different work stations.

Four,Overhead Chain Conveyor Line

For production environments with high cleanliness requirements, overhead chain conveyor lines can maximize the protection of products from contamination while maintaining conveying efficiency.

- Core Parameters:Maximum load of single section is 200kg, maximum conveying length is 8m, plastic overhead chain is used as conveying medium, load limit per unit length is 0.5kg/cm;

- Applicable Scenarios:Light-load product conveyance with high cleanliness requirements such as optoelectronic manufacturing, medical equipment, etc., suitable for dry and pollution-free production environments;

- Product Highlights:Self-configurable frequency converter speed regulation, support stacking operation and forward and reverse operation, modular design for easy installation and maintenance, high positioning accuracy, with standard pallet can realize accurate conveying, meet the anti-static requirements.

Five,Selection Tips: Match Your Needs Without Stepping on Pitfalls

In fact, the logic of pallet conveyor line selection is very simple, the core around 3 key points:

- Depends on the load: choose synchronous belt for light load (≤60kg), flat belt for medium load (≤250kg), and speed chain for heavy load (≥2200kg);

- Look at the distance: short distance (≤6m) priority synchronous belt, medium and long distance (230m) choose flat belt or double speed chain, 8m within the high clean demand choose overhead chain;

- Look at the environment: choose synchronous belt or overhead chain for clean environment, choose doubled speed chain for harsh environment or heavy load, choose flat belt for long distance clean scene.

VI. About Wei Chuang Automation

Wei Chuang AutomationAs a source manufacturer of pallet conveyor system for 10 years, all lines have been tested for 10,000 hours of full load life, and the service life can be more than 3 years. We support non-standard customization according to workshop layout and production conditions, compatible with jacking and positioning, elevator and other supporting equipment, fast delivery far exceeding the industry average, and national after-sales service network can respond to technical support in a timely manner.

If you still want to combine your own production needs, to get more accurate selection advice or customized solutions, welcome to contact Wei Chuang professional team, let theModular Pallet ConveyorThe system improves the quality and efficiency of your production line.