In the wave of modern industrial development, production equipmentAutomation upgradesHas become an inevitable trend. However, many companies in promoting this process, but generally encountered a “hot under the cold” embarrassing situation: management keen to introduce advanced equipment, the front-line staff are not interested. Behind this phenomenon, what problems are hidden? And how to crack it?

One,corporationspull intoAutomation Equipment Frequently Asked Questions

1,conflict of ideas

The enterprise's production model is mostly characterized by multi-species, small batch, which is a natural contradiction with the single product mass production that automation equipment is good at. Frequent adjustment of the machine is not only technically difficult, learning costs, deeper reasons, employees of automation equipment may cause unemployment concerns, making them in the early stages of the introduction of equipment will be negatively resisted, and even questioned the practicality of automation equipment.

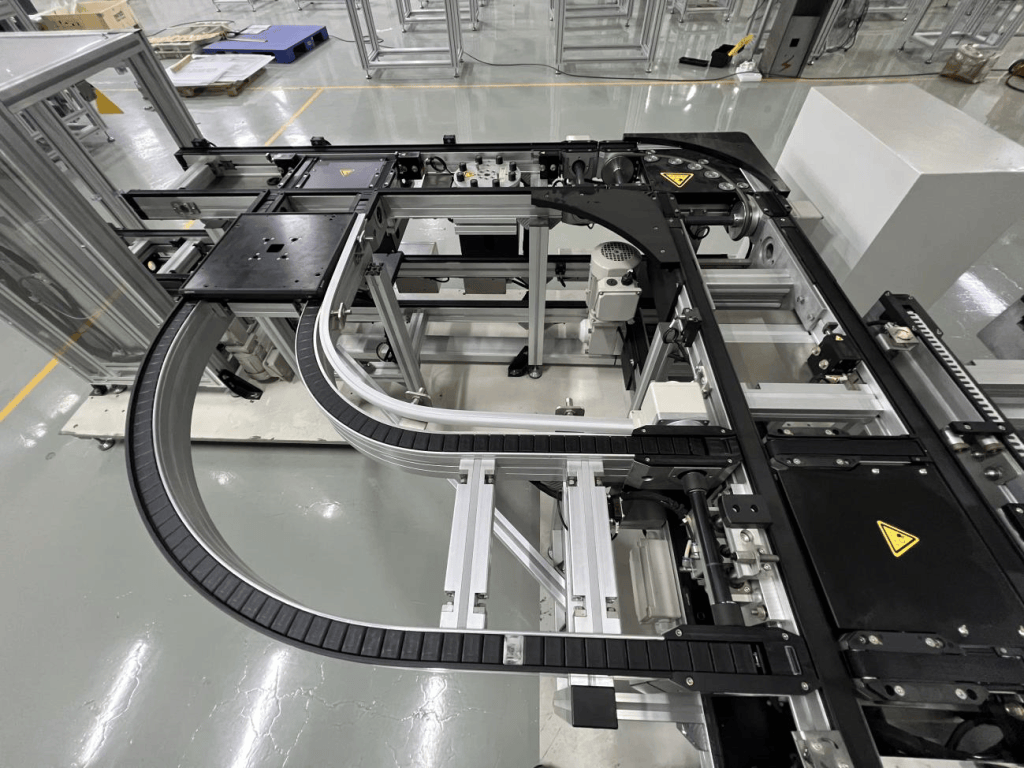

2,Lack of versatility

When introducing automation equipment, some companies lack systematic planning, focusing only on immediate production problems and ignoring market changes and future product characteristics. This leads to the lack of versatility and flexibility of the equipment, which can only be adapted to a small number of products. Once the order is reduced, idle equipment, waste of resources will be inevitable, the enterprise also has concerns about further investment in automation equipment.

3,Evasion of responsibility

The introduction of automation equipment is not a one-day process, the market has a limited number of mature solutions, and companies often need to communicate with suppliers in depth to customize. However, in the face of the frustration and pressure of this complex process, some of those responsible choose to give up easily, unwilling to take responsibility, resulting in halfway through the project.

4,Poor system fit

The efficient operation of automation equipment often relies on multi-departmental collaboration. For example, if the scheduling plan of the production department fails to match the demand for the use of the equipment, such as splitting the arrangement of products that could have been produced together, it will significantly increase the frequency of transferring the machine, further aggravate the resistance of employees, and jeopardize the consistency of the automation promotion.

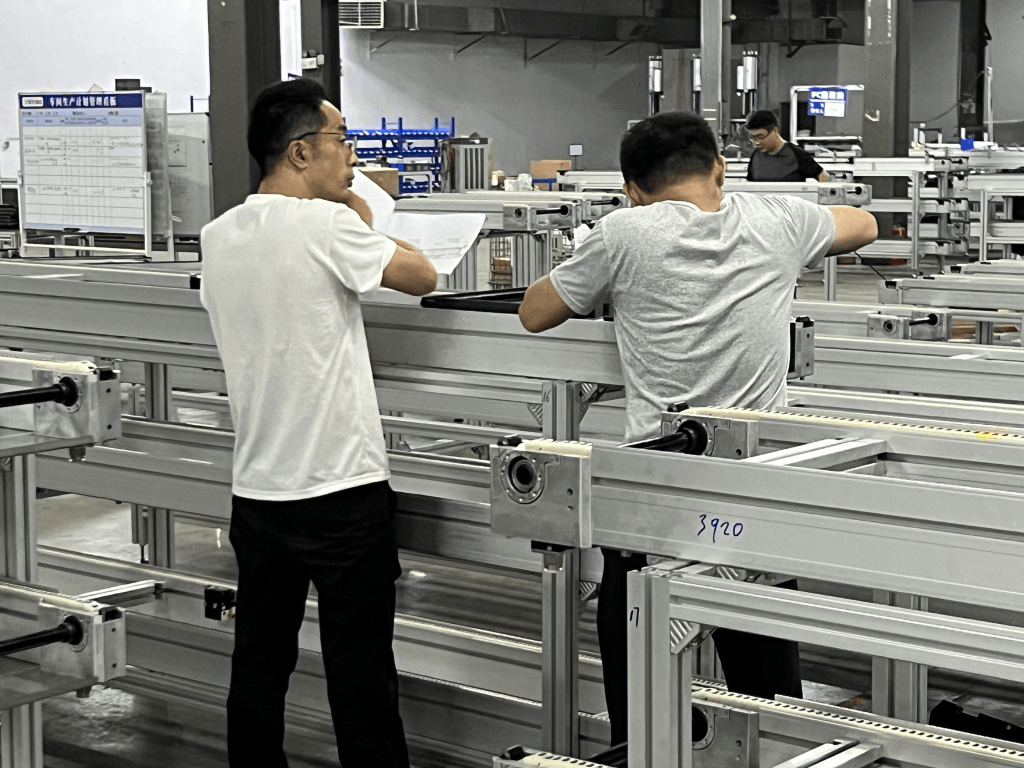

5,Communication and acceptance omissions

Enterprises in the equipment procurement process, if gullible suppliers publicity, without adequate communication on the order, and did not let the front-line staff to participate in the selection, easy to lead to equipment does not meet the needs. In addition, if the acceptance link is sloppy, not to ensure that employees are skilled in the operation and adjustment of the machine method, the subsequent production problems occur frequently, but also prone to suppliers to assist the possibility of ineffective.

Two,How do I automate the right import?

l Developing a “lazy” mindset

Managers need to change their mindset and proactively explore the parts of the production process that can be replaced by machines, or positions that make employees“ work easier. This ”lazy" wisdom is actually a keen eye for automation opportunities.

l be good at borrowing strengths

In the face of heavy resistance in the automation process, whether it is internal coordination problems or external technical bottlenecks, enterprises should actively leverage the power of leaders, organizational resources, and even external experts to break through the barrier.

l face up to failure

Project failure is not uncommon in automation. The key lies in whether the person in charge can face the setbacks with courage and commitment, and learn from the experience instead of choking on it. This spirit of trial and error is the driving force behind automation.

l choose wisely

Enterprises need to set automation goals based on their own actual situation, to avoid the blind pursuit of the whole. For small and medium-sized enterprises with limited resources, simple automation or semi-automated equipment may be a more pragmatic choice, because the core value of automation is to save people and energy, rather than the pursuit of high-end.

Three,Pinpointing: Identifying Automation Opportunities

Companies should focus on the following positions and processes to accurately identify opportunity points for automation introduction:

1. Bottleneck processes:Automation can be a powerful tool for breaking bottlenecks in those areas where productivity is severely constrained.

2. Cumbersome labor processes:Automation can significantly reduce labor costs for jobs that use a lot of labor and have repetitive and tedious work content.

3. Scrutinize posts:Large batch sizes, small specifications, and high visual inspection requirements, automated inspection can improve accuracy and efficiency.

4. Repeat the carrying action:Frequent lifting and carrying movements in the production process are ideal application scenarios for automation

5. Error-prone posts:Automation can dramatically improve product consistency and reliability in areas that are prone to human error.

6. Dangerous posts:Automation not only improves efficiency, but also protects the safety of employees in jobs that are dangerous and prone to workplace accidents.

IV. Staff support - introductionThe cornerstone of automation success

Why do organizations often lack employee support when introducing automation equipment?

The root of the problem is that employees are skeptical about the distribution of benefits that come with automation in the enterprise. They worry thatEfficiency gainsAfterward, the unit price of product processing is adjusted downward, which in turn affects personal income. Therefore, when promoting automation, enterprises must take the interests of employees into account and gradually eliminate their concerns. Automation should not be a cold technological replacement, but a deep integration of efficiency and humanity.

The road of automation upgrade is the key for enterprises to move towards efficient and intelligent production. Enterprises can't just automate for the sake of automation, but to import suitable equipment and reach coordinated conditions in order to truly realize the value of automation.