Description

Jacking Rotation.

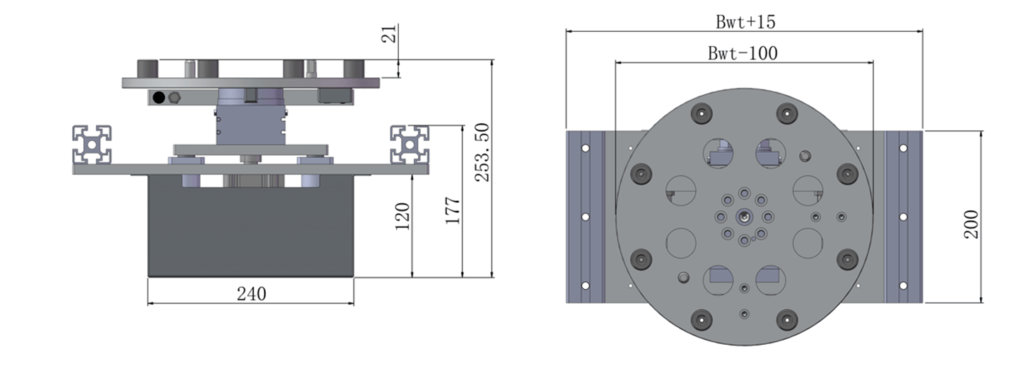

- Supported pallet width /mm. 160, 240, 320, 400, 480, 640 (160≤Bwt≤640)

- Supported tray length /mm. 160, 240, 320, 400, 480, 640 (160≤Bwt≤640)

- Support Angle. 90° or 180°

- Driving method :cylinder (engine)

- Maximum load /kg. 30 or customized

Key Benefits

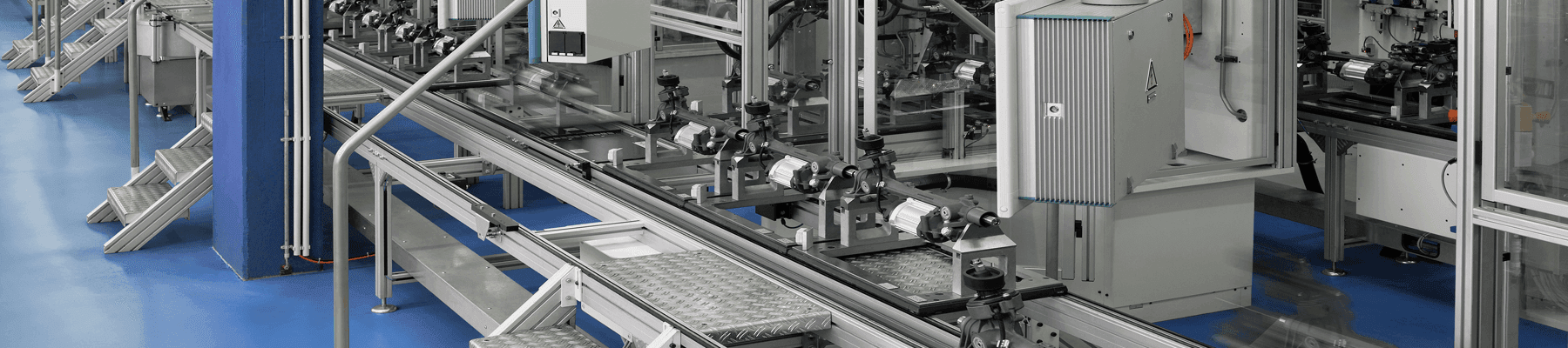

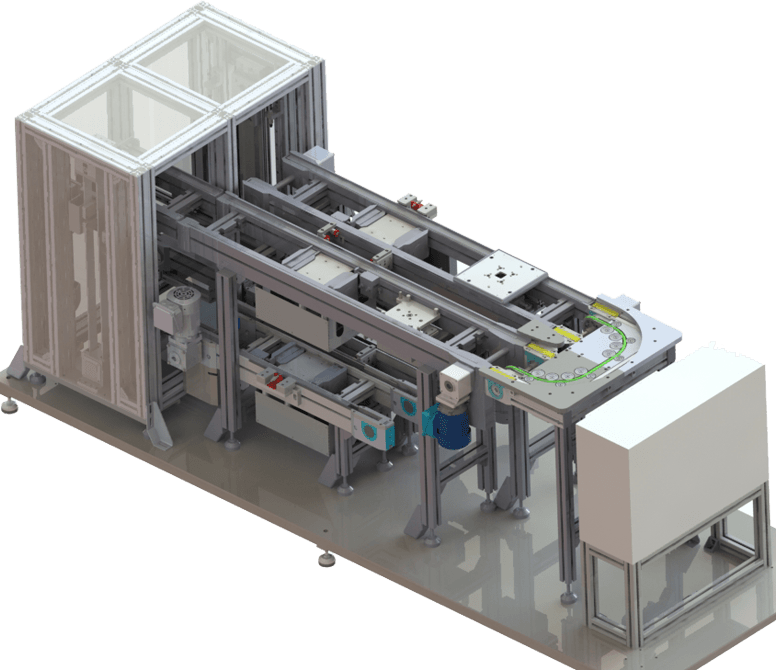

- Increased precision and flexibility: the jacking swivel is a pioneering mechanism that perfectly combines the functions of a lateral and a swivel device in a single multifunctional unit. The orientation of the pallet can be dynamically adjusted to ensure a smooth, uninterrupted flow.

- More functionality: The function of the jacking swivel is similar to that of a turning device, but it goes one step further by integrating lateral and swivel functions. This dual functionality not only enhances the adaptability of the conveyor system, but also opens up new possibilities for efficient material handling in a variety of production scenarios.

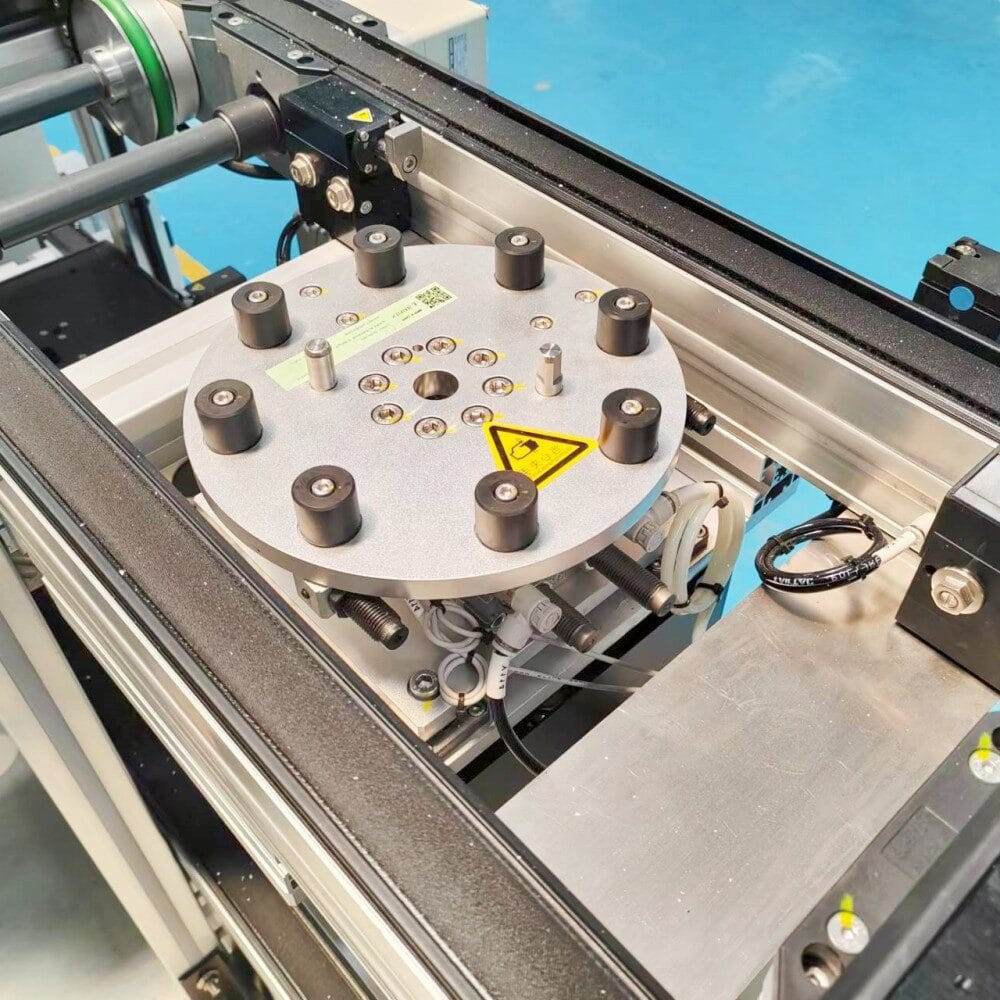

- Accuracy and synchronization: The jacking and rotating uses synchronous belts as the transfer medium and is driven by stepper motors. The lifting and rotating motions of the unit are coordinated by the lifting and rotating cylinders respectively, adding an extra layer of control and customization to the conveying process.

- Maximizing Space Utilization: Widely used in pallet conveyor systems, the jacking swivel has become a common and important component. It not only addresses the limitations of lateral units, but also provides a space-saving solution to the space challenges posed by curved units.

mileage

Seamless integration of landscape and rotary functions.

Mitigating the challenges of pallet forward movement.

Efficient use of space compared to conventional curved units.

Precision synchronized drive using timing belts.

Driven by stepper motors, lift cylinders and rotary cylinders.

More efficient solutions

As production processes continue to demand greater precision, adaptability and spatial efficiency, the jacking swivel stands out as a reliable, innovative solution. It seamlessly integrates lateral and rotary functions, marking a significant advance in the quest for more efficient and versatile conveyor systems.