In modern industrial automation, thePallet conveying lineAs an efficient and flexible material handling system, it has become an indispensable production tool for many manufacturing companies. How much do you know about it? Next, we can deepen our understanding of pallet conveying line through the following contents:

I. Brief definitions

A pallet conveyor line is a type of conveyor line that passesWorkpiece palletsAn automated conveyor system for transporting various products. Pallets are usually transported by conveyor media such as belts, roller chains, flat-top chains, or powered rollers, and are capable of precise positioning on the conveyor line. And pallets are in most cases manufactured in standard sizes, although many automation companies of course offer customised services.

The core components of a pallet conveyor line include:

Conveying medium:as ifTiming belts, flat belts, doubling chainsmaybeplaten, responsible for the physical transport of the pallets.

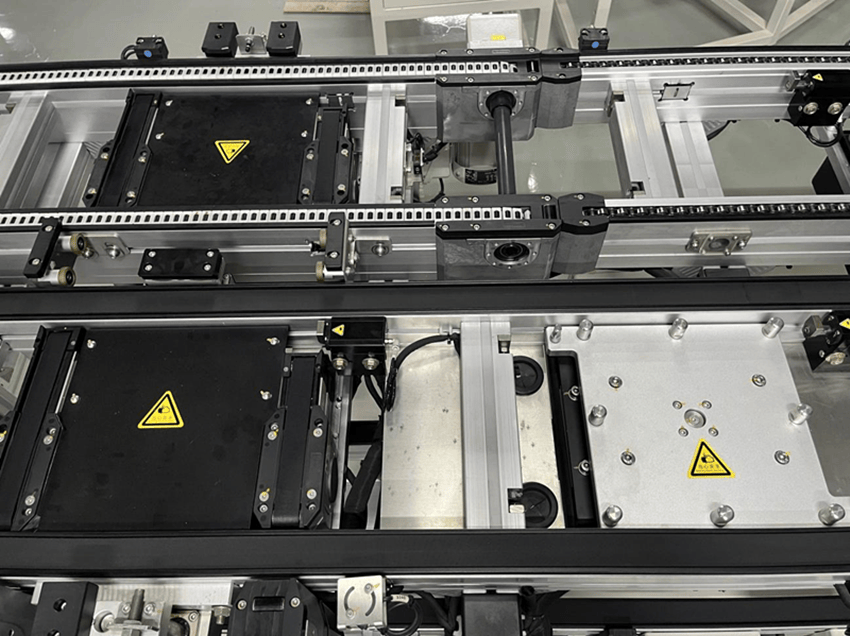

Tray:As a platform for carrying products, pallets usually have standardised dimensions and support customised designs to suit different product specifications.

Positioning device:Such as a stopper,jacking positionerThis ensures precise positioning of the pallet on the conveyor line.

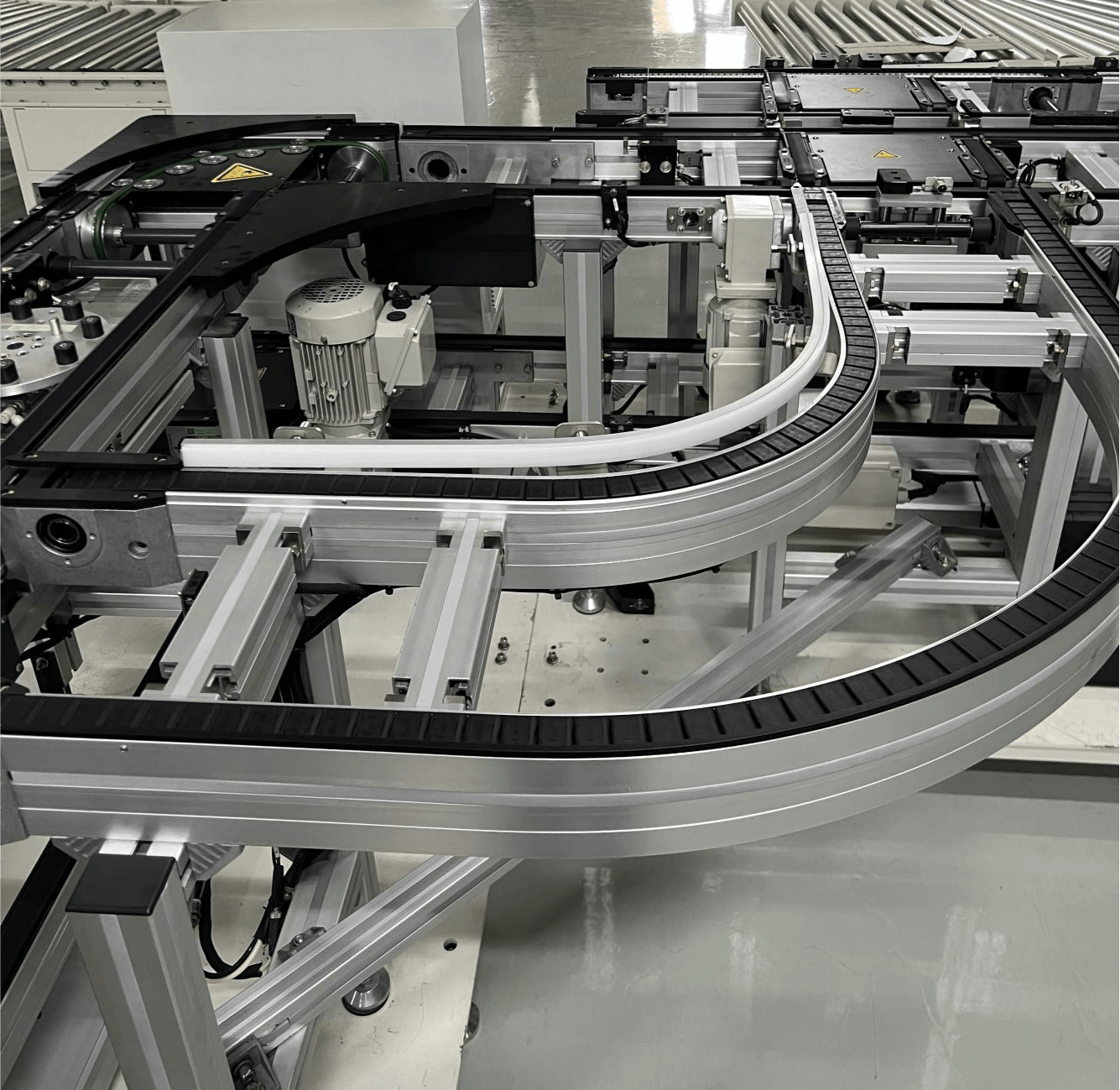

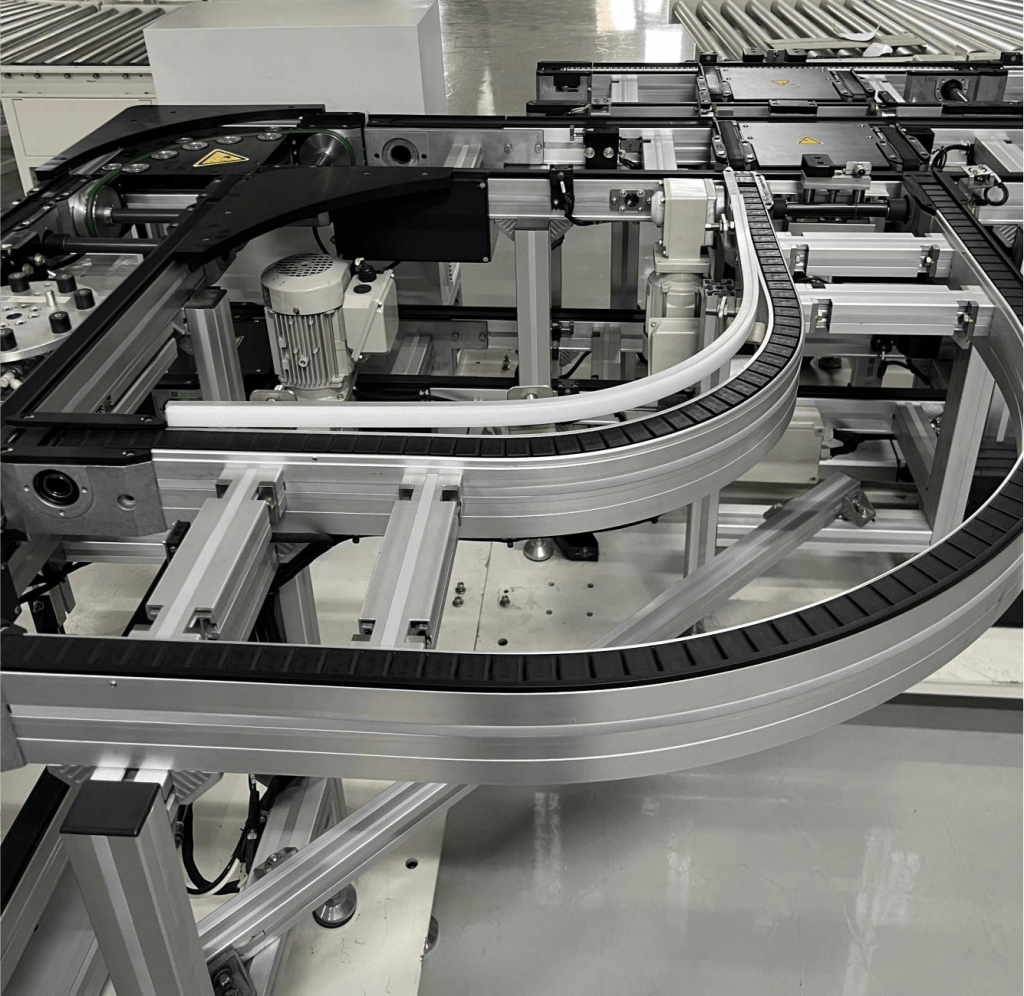

Turning Module:For example, flat-top chain curves or round belt curves for pallet steering and multi-path conveying.

Lifting and rotating units:Allows asynchronous movement of pallets at different heights and directions.

The combination of these modules allows the pallet conveyor line to be flexibly adapted to a variety of complex production scenarios, providing the ideal solution for high-precision assembly, machining, inspection and positioning tasks.

Second, the advantages of pallet conveying line

1,High precision positioning

Pallet conveying lineEnables precise positioning of pallets, often within ±0.5mm. This high accuracy positioning is critical for industries that require precise docking, such as automotive assembly, electronics assembly and semiconductor production.

2,Modular design

The Pallet Conveyor Line has a modular design for easy installation, maintenance and expansion. This design not only improves productivity, but also ensures the flexibility and expandability of the equipment to meet changing market demands.

3,High load capacity

Depending on the conveying medium, the load capacity of pallet conveyor lines ranges from tens of kilograms to several tonnes. For example, multiplier chain conveyor lines have a load capacity of up to 4,000kg in a single section, while timing belt conveyor lines are suitable for scenarios with light loads and high cleanliness requirements.

4,Cleanliness and Durability

Many palletised conveyor lines are made of anti-static materials and wear-resistant designs for industries that demand the highest levels of cleanliness, such as lithium-ion, 3C electronics and food processing.

Three,application scenario

The wide range of applications for palletised conveyor lines makes them the preferred solution for a number of industries:

New Energy and 3C Electronics:in the production of new energy batteries and 3C electronic products.Pallet conveying lineIt is able to meet the requirements of high cleanliness and high precision to ensure product quality and production efficiency.

Food & Drink:The food processing industry requires strict hygiene standards and the pallet conveyor line ensures the safety and hygiene of foodstuffs during conveying through its anti-static and wear-resistant design.

Medical and Pharmaceutical:In the production and packaging of pharmaceuticals, the high level of cleanliness and precision of palletised conveyor lines provides a reliable guarantee of the quality of pharmaceuticals.

Automotive Manufacturing:Pallet conveyor lines play an important role in the assembly and assembly of automotive components, ensuring accurate docking and efficient production of individual parts.

Wei Chuang Automation

Weichuang has more than 10 years ofPallet conveying systemsand related modular accessories R & D and manufacturing experience, long-term commitment to automated assembly line equipment production, processing, sales, to provide users with high-quality, professional automated conveyor systems and one-stop service, so that customers experience a professional, caring selection and procurement process.

The products are widely used in various fields such as new energy, 3C electronics, lithium-ion battery, food, beverage, medical and automobile manufacturing.