In modern industrial production, efficient material conveying equipment is the key link to realise automated production and logistics. As a widely used conveying equipment, chain conveyor line, with its unique performance and advantages, has become the right hand of many enterprises production. Today, let's get to know more details about chain conveyor line.

I. Chain conveyor line overview

Chain conveyor line is a kind of equipment that uses chain as traction, carrier or conveying medium for material conveying or turnover. It can be flexibly adjusted according to the actual application requirements, and there are various types of lines, including roller chain conveying lines, double pitchChain conveyor lineand other conveyor lines with accessory chains, etc.

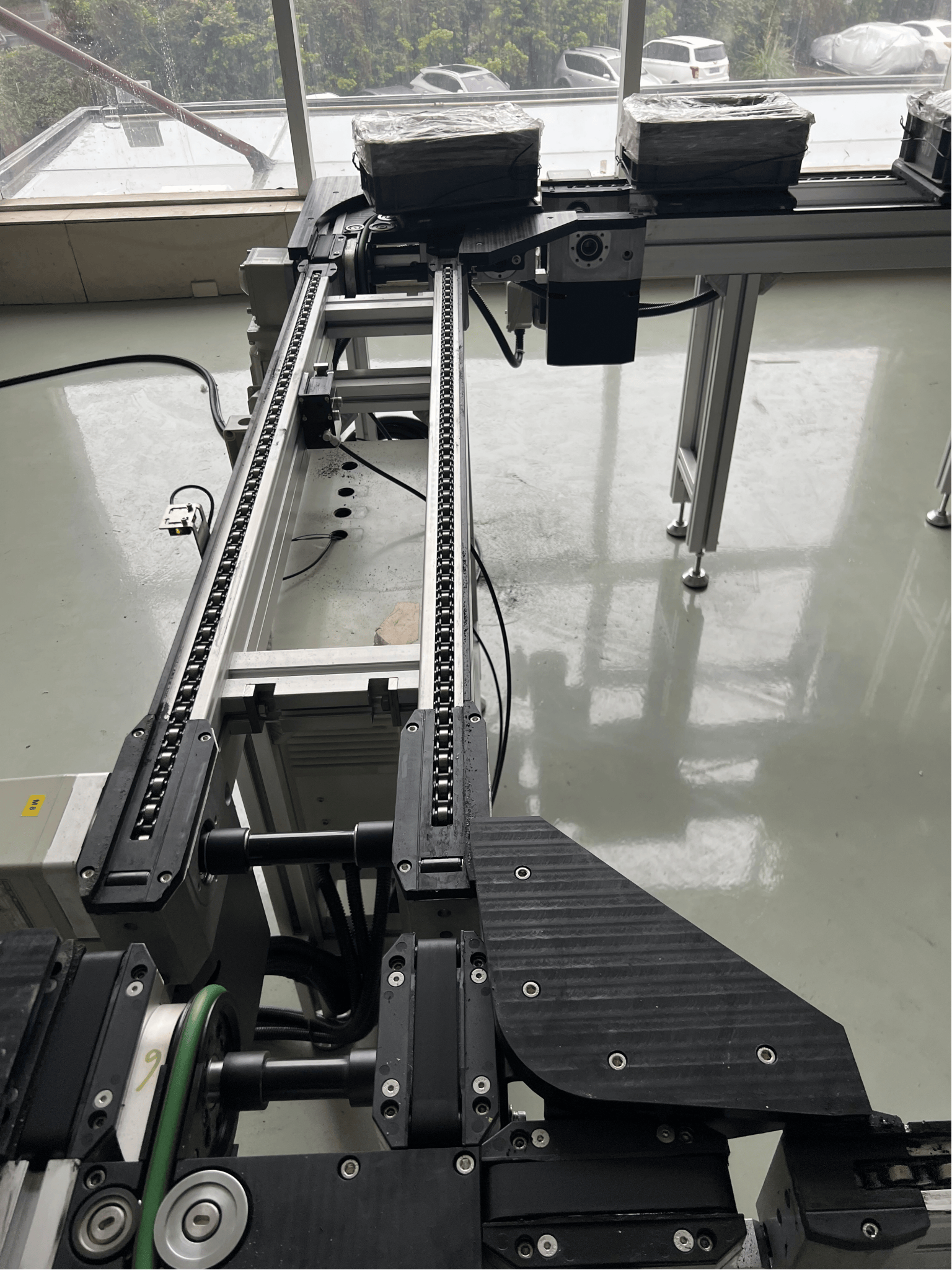

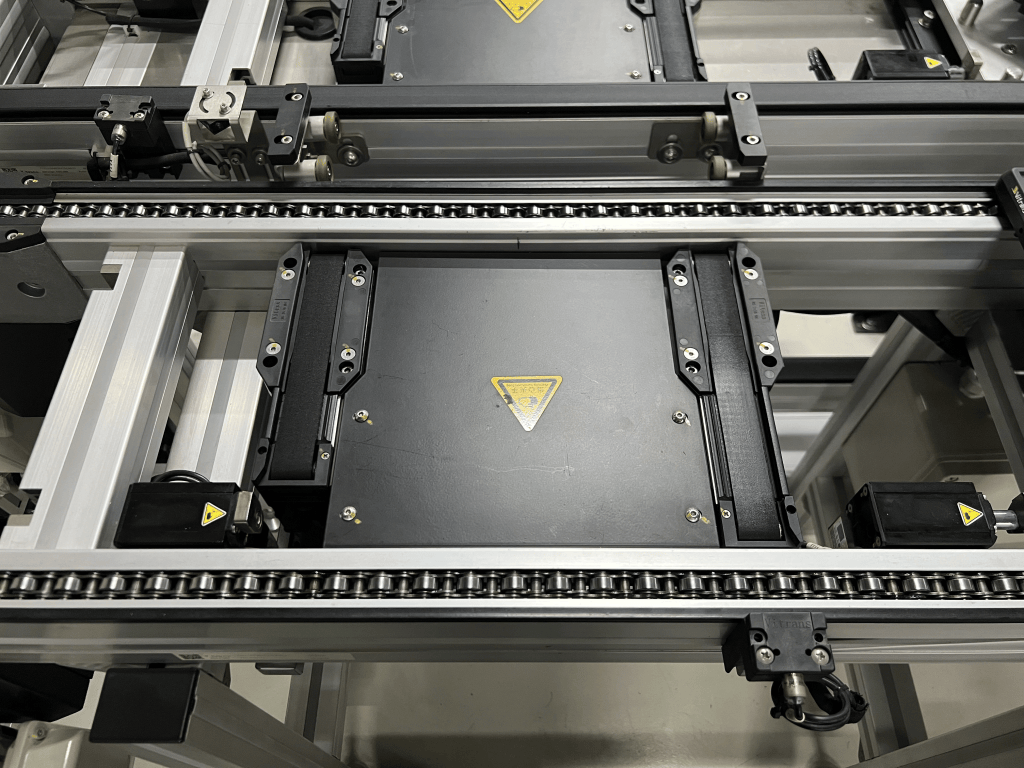

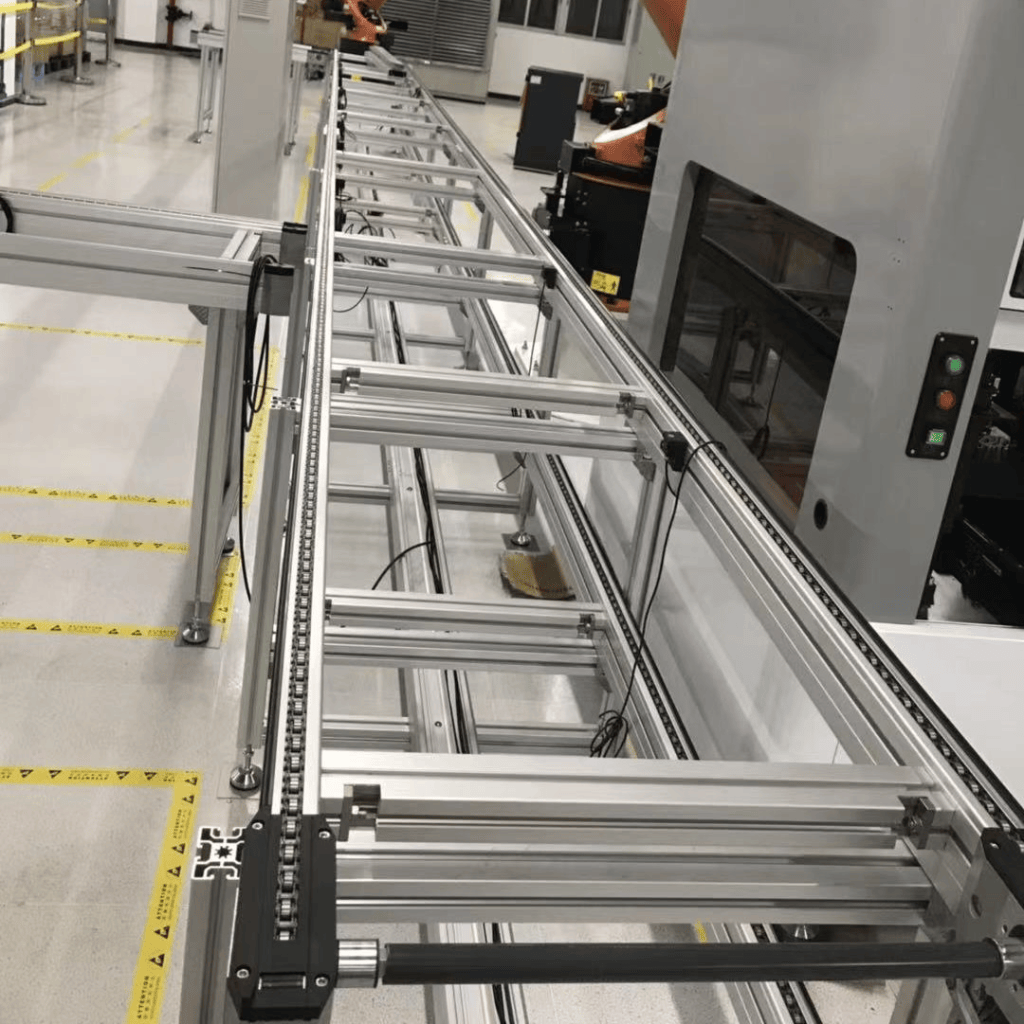

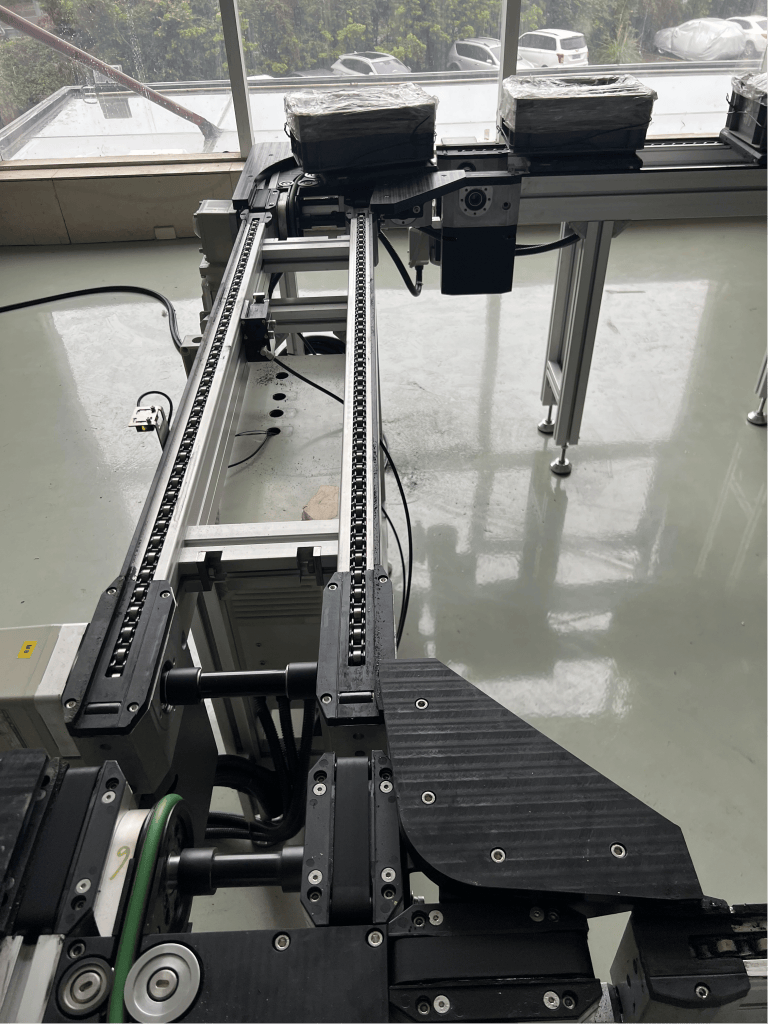

II. Structural composition of equipment

Chain conveyor lines are mainly composed of the following key components:

1. Driving force: Generally from the motor, to provide power support for the operation of the conveyor line.

2. Driving device: It consists of supporting parts, sprocket and driving motor, etc., and is responsible for converting the kinetic energy of the motor into the movement of the chain.

3. Conveying medium: It includes conveying chain, chain plate and related accessories, which are in direct contact with the materials to realise the bearing and conveying of materials.

4. Line frame: As a support structure, it provides stability and support for the entire conveyor line.

5. Drive control: Through the control system, the speed, start and stop of the conveyor line can be precisely controlled to meet the needs of different production scenarios.

Third, the advantages of chain conveyor line

Chain conveyor lines offer a number of significant advantages:

1. Avoiding the phenomenon of elastic sliding and skidding, ensuring the stability and accuracy of material conveying.

2. Precise transmission ratio, smooth running, effectively improve working efficiency, reduce material accumulation and waiting time in the production process.

3. Able to transmit large power, with strong overload capacity, suitable for heavy-duty material conveying.

4. Under the same working conditions, the design dimensions are more compact, requiring less tensioning force, reducing space occupation and equipment wear.

5. Strong adaptability, can work stably in high temperature, humidity, dusty, polluted and other harsh environments, not limited by environmental factors.

IV. Application scenarios

chain conveyorWidely used in many fields:

1. Automobile manufacturing:It is used in the production assembly line of automotive parts, such as the conveyance and assembly of engine, transmission and other parts, which can bear the weight of the parts and ensure the accuracy of assembly.

2. Electrical and electronic industry:In the production of electronic products, such as TV sets, computers and other assembly lines, chain conveyor lines can achieve efficient and stable material transport to meet the requirements of electronic production on the environment and precision.

3. Food and beverage industry:It can be used in the conveyor link of food processing and beverage production, such as canning and packaging, etc. Its high temperature and humidity resistance enables it to adapt to the special environment of food and beverage production.

V. Sample cases

With a parts assembly conveyor line (Speed Chain LineFor example, the assembly line adopts a horizontal ring layout, which is matched with the customer's specialised assembly equipment to form an automated assembly line. The single-speed chain line is stable in conveying and can withstand large loads, and it also has an accumulation function, which effectively reduces the wear and tear of the conveyor pallet. The whole line has a strong load capacity of 2000kg without any problem, and the conveying process is smooth and reliable.

Selecting the rightchain conveyorIt can not only improve the production efficiency, but also reduce the operation cost and create more value for the enterprise. If you are interested in chain conveyor line or have related needs, please feel free to consult us for more detailed information and customised solutions.