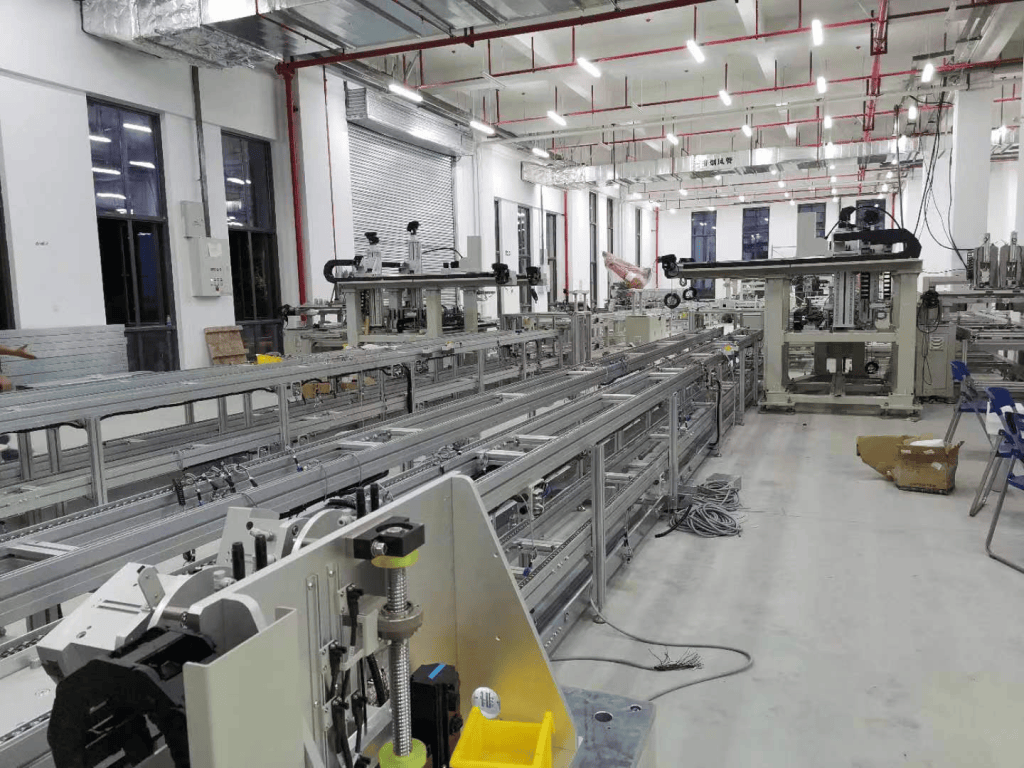

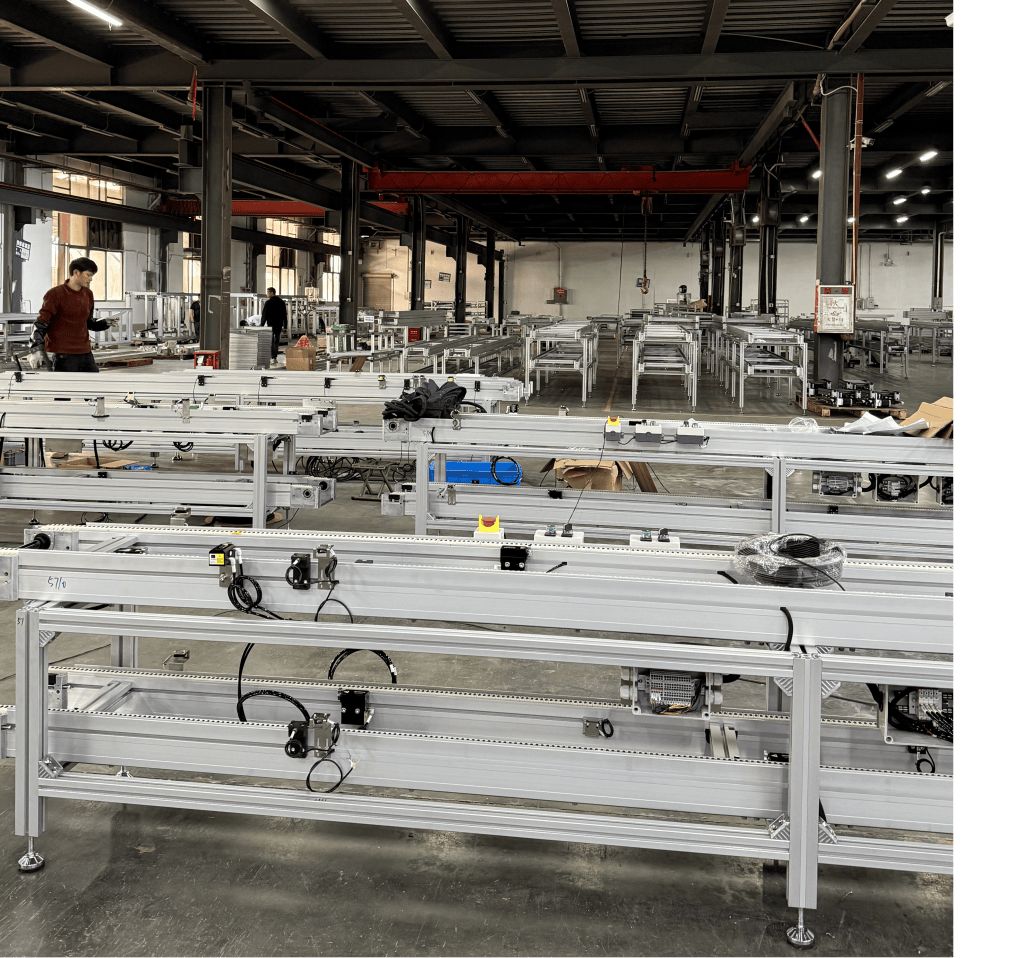

Wei Chuang Automation is a long-term production, processing and sales of automated assembly line equipment, is committed to providing users with high-quality, professionalPallet conveying systemsand customised services. Relying on the perfect combination of lean and flexible production mode, to meet the customer's multi-model, large-scale, small batch, personalised market demand.

(i)Customer Pain Points

Productivity is not high:Slow conveyor speed and long production line downtime in the original line

Frequent equipment breakdowns and repairs:Conveyor breakdowns and repairs often lead to line downtime, increasing maintenance costs and reducing line reliability and stability.

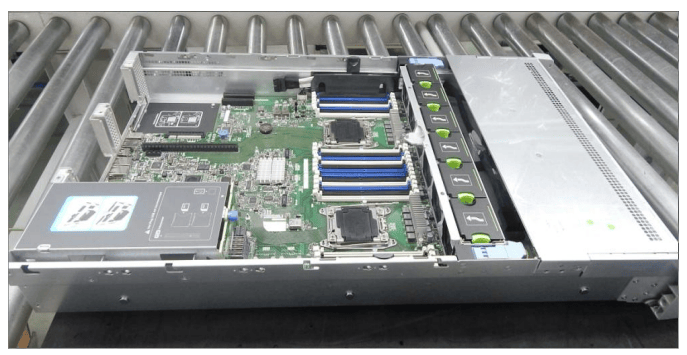

Production information is not fed back in a timely manner:Unable to know the defective rate of products in time, quality control is particularly difficult

Carrying waste:Time-consuming and labour-intensive assembly process

(ii)prescription

①Elevator

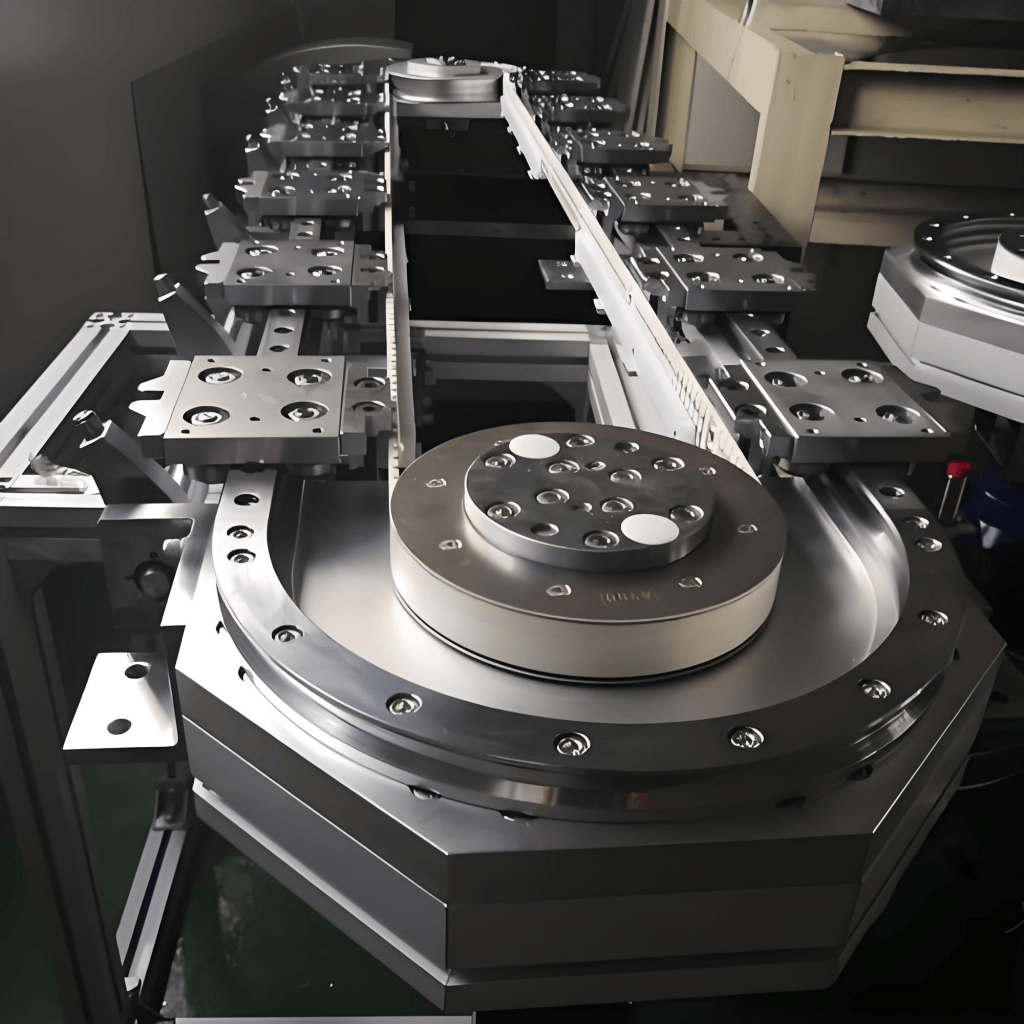

②Top lift traverse

③ 6 metre belt line

④ 10 metres of multiplier chain line

⑤Upper and lower floor design, small footprint

(iii)sports eventeffect

1,Increased productivity

The production line has significantly increased productivity through streamlined operations and a high degree of division of labour.

2,Reduction of production cycle time

The automated production line enables multiple processes to be carried out simultaneously, helping to increase production capacity.

3,Reducing waste and errors

The production line is designed so that each step of the process is delicate and independent, reducing waste and errors due to the human factor, thus reducing costs.

4,Stable product quality

Optimised and standardised production processes and monitoring by specialists ensure consistent product quality.

Wei Chuang Automation

Main products areBelt Conveyor Line, Speed Chain Line, Chain Plate Line, Roller LineThe automated assembly and logistics products are widely used in automotive parts, lithium-ion battery, photovoltaic, 3c electronics, medicine, lighting and other industries. The company has an independent technology research and development team, complete supply chain system, technical installation and after-sales service team with rich experience, adhering to the concept of customer-centred, committed to the manufacturing industry to reduce costs and increase efficiency, to provide enterprises with lean, automation and information technology one-stop overall solutions.

If you have further needs or questions about conveyor lines, please feel free to contact us, we will provide you with detailed technical advice and customised services.