in the field of industrial automation.Pallet conveying systemsAs a key logistics equipment, its stable operation directly affects the production efficiency. How to ensure a smooth production process, as far as possible without any accidents and incidents? Attaching great importance to the daily maintenance of the system is the key, the following arePallet conveying systemsThere are several areas to focus on during operation and maintenance:

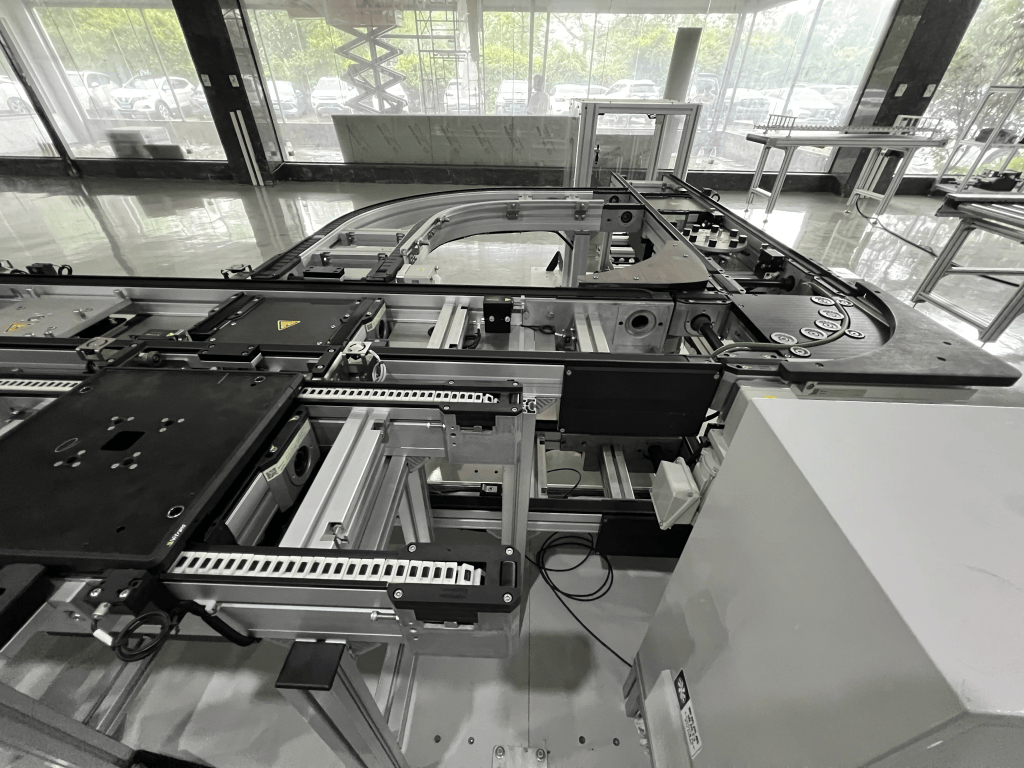

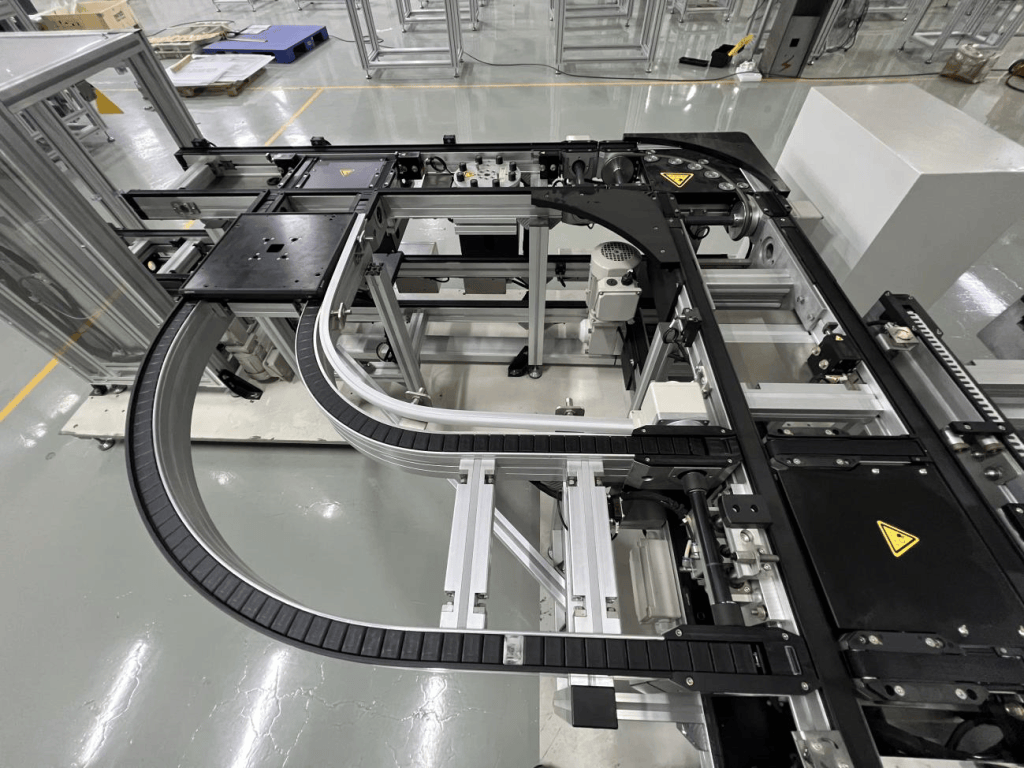

Pallet conveying systems

Pallet conveying systemsIt is an automated logistics equipment for efficient transfer of materials in the production process. It consists of pallet, conveying line, driving device, control element and various modular mechanisms. Through chain, belt and other transmission methods, the pallet can transport the parts to be processed from one station to another, realising the automated flow of materials, which is widely used in new energy, automotive parts, electronic and electrical appliances, motors and other industries.

There are four main points to focus on during the operation and maintenance of a pallet conveyor system:

I. Daily adherence to inspections

1. Check the conveyor chain or belt: check whether there is looseness, wear and tear and runaway phenomenon, and whether the tension is appropriate.

2. Focus on transmission components: check the motor for abnormal noise and vibration, and whether the temperature is normal.

3. Check the conveying track: make sure the surface of the track is flat and there is no accumulation of debris to hinder conveying.

4. Confirm the working status of the sensors: Ensure that the position sensors, weight sensors, etc. are sensitive and the data transmission is accurate.

Second, do a good job of cleaning and maintenance

1. Regular cleaning of conveying equipment: use special tools to remove dust, oil and other impurities from chains, rails, boxes and other parts.

2. Lubricate key moving parts: lubricate chains, bearings, etc. after cleaning to reduce wear and prolong equipment life.

III. Periodic calibration

1. Calibration of sensors: Calibration of various types of sensors to ensure that the measurement accuracy meets the requirements.

2. Precise calibration of conveying parameters: calibration of parameters such as conveying speed, start-stop position, etc., to match the actual production requirements.

3. Preventing conveying accidents: avoiding accidents such as collision and falling caused by excessive speed or improper starting and stopping, and ensuring the smooth conveying of goods.

IV. Timely troubleshooting

1. Rapidly determine the fault: maintenance personnel need to quickly determine the type and location of the fault phenomenon.

2. Standardise the maintenance operation: the maintenance must strictly follow the operation specification and not dismantle the equipment at will. For common faults, such as chain breakage, sensor malfunction, etc., spare parts should be prepared in advance for timely replacement.

3. Record the details of the fault: after handling the fault, record the details of the fault and the process of handling, analyse the causes and sum up the experience.

Five,Pallet conveyor systems forAdvantages and Applications

Pallet conveying systemsWith its modular design, it enables efficient installation and maintenance. It supports a variety of conveyor line bodies, such as synchronous belt, flat belt, doubled speed chain, roller line, etc., to meet the needs of different production scenarios. The system is widely used in new energy, automotive parts, electronic appliances, electric motors and other industries, which can significantly improve production efficiency, reduce labour costs, and enhance the cleanliness and safety of the production environment.

Pallet conveying systemsRigorous and meticulous maintenance is indispensable for the stable operation of the system. By adhering to daily inspections, good cleaning and maintenance, regular calibration and timely troubleshooting, we can ensure that the system continues to operate stably, which will strongly promote the smooth implementation of production activities.