In today's industrial Internet of Things era, intelligence and networking are becoming the core trend in the field of logistics and conveying. Material conveying system is becoming more intelligent and efficient, in which conveying equipment plays a key articulation role, which can not only complete the task of conveying items, but also has a buffer function to help enterprises to significantly shorten the transport time, improve the quality and efficiency of goods management.

With regard to logistics conveying lines, they can be divided into the following categories according to the different forms and devices of conveying:

I. Pallet conveying series

Pallet conveyingseries is a highly flexible and powerful conveyor system consisting of synchronous belts,Stacked roller chainsThe system is a combination of various modules, such as jacking and positioning, jacking and traversing, round belt turning, elevator, stopping and palletising. This combination gives the system a high degree of flexibility and enables it to be easily adapted to a variety of different application scenarios.

l Features:

- Manufactured with high strength materials to ensure stable operation even under long time and high intensity working conditions.

- Excellent abrasion resistance keeps them in good working condition under frequent use, reducing maintenance costs and equipment downtime.

l Applications:

Pallet conveyor series are widely used in various manufacturing and logistics industries. Whether it is the production of automotive parts, or the manufacture of electronic products, or the sorting and transport of goods in logistics warehouses, it can play an important role. It can realise the functions of automatic pallet conveying, stacking, storing and transferring, etc., and provide efficient and flexible logistics solutions for enterprises.

Second, roller conveyor series

roller conveyorIt is an important equipment to realise efficient material conveying, especially suitable for conveying crates from automatic three-dimensional warehouse to calibration system and other links. It adopts double-sided friction belt transmission mode, which ensures the stability and accuracy of materials in the conveying process.

Features:

- The outer edge of the conveyor frame is covered with stainless steel guard plate, and the outer side is equipped with guiding device, which not only can effectively protect the equipment and prolong its service life, but also can precisely control the width of the channel to ensure the smooth transmission of the crate and avoid the occurrence of jamming phenomenon.

- Roller conveyor lines are able to easily transport materials with large single piece weights or withstand large shock loads.

III. Belt Conveyor Series

belt conveyorIt is a kind of continuous conveying equipment using conveyor belt as material bearing and traction member. It plays an important role in the sorting operation of the logistics and express delivery industry, and can realise continuous and large-volume sorting of goods.

Features:

- Belt conveyor can be used for conveying and sorting of packaged goods such as boxes and bags, and its continuous and stable running characteristics make the goods sorting process efficient and low error rate.

- It can realise continuous conveying of materials with low operating cost and high reliability.

- Simple structure, easy maintenance, suitable for long time stable operation.

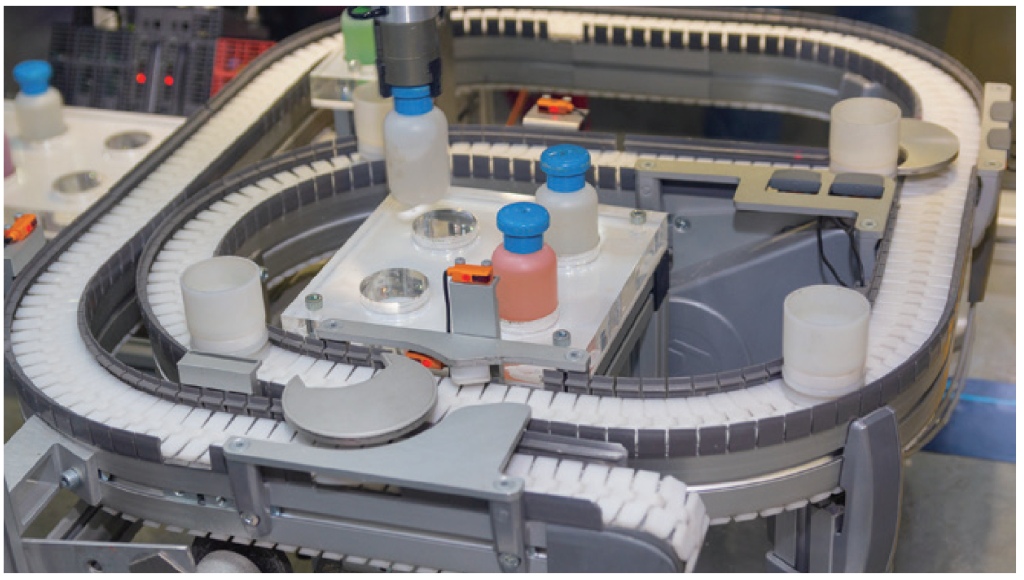

Fourth, flexible chain plate series

Flexible chain conveyor lineIt provides a stable and reliable horizontal bearing surface for material conveying, and its chain plate width can be customised according to the specific requirements of the conveyed materials.

Features:

- The conveying surface is designed to be flat and smooth with low friction to ensure smooth and smooth transition of materials between different conveying lines.

- It is suitable for conveying all kinds of irregularly shaped items, such as glass bottles, PET bottles, cans, etc., and can also easily handle all kinds of luggage conveying tasks.

Applications:

Flexible chain conveyor lineWith its unique flexibility and adaptability, it is widely used in food, beverage, daily chemical and other industries. Whether it is material transfer on the production line or product conveying on the packaging line, it can ensure the smooth movement of the items, reduce the loss, and bring significant economic benefits for the enterprise.

V. Conclusion

The logistics conveyor line is the core of logistics automation, from pallet conveying to theroller conveyor, and then to the belt conveyor and flexible chain plate conveyor, each kind of conveyor equipment plays an important role in the logistics chain. Choose the right logistics conveying equipment, so that every piece of material in the flow of the conveyor line, the enterprise from the real digital transformation, may not be far away.