roller conveyorIt refers to the machinery that can convey materials with large weight of single piece or bear large impact load. It is suitable for conveying all kinds of boxes, bags, pallets and other pieces of goods, bulk materials, small items or irregular items need to be placed on the pallet or in the turnover box conveyor. In industrial automationroller conveyorAs an efficient and reliable conveying equipment, it is widely used in all kinds of production scenarios. So, what do we need to pay attention to when choosing roller conveyor line?

One,platen(used form a nominal expression)formbe all right

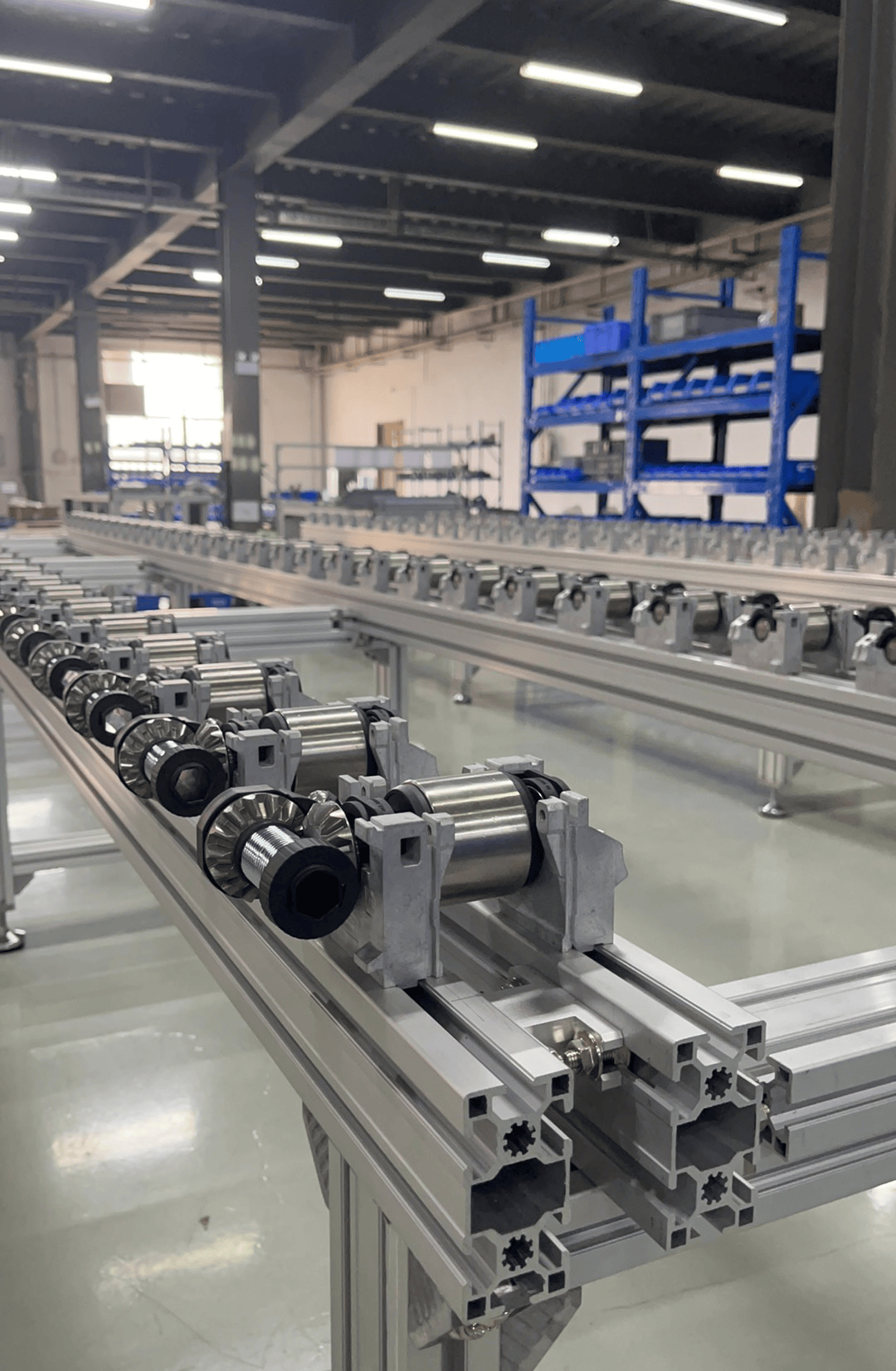

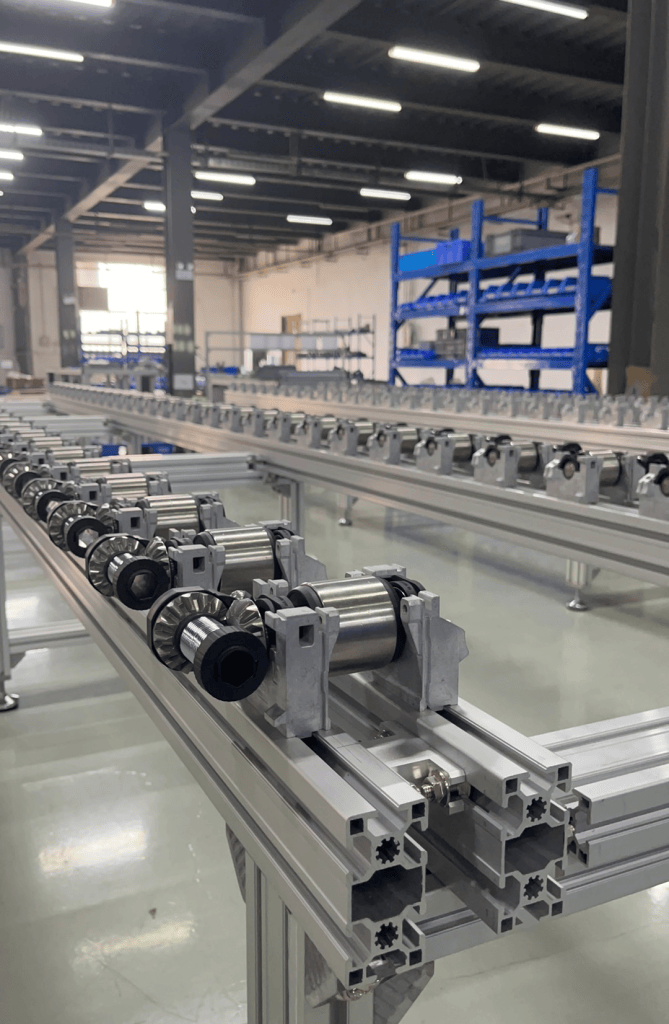

roller conveyorIt is mainly composed of roller, bracket, transmission device and other parts. Both sides of the drum are usually fixed with bent sheet metal, and the connection between the drum and the sheet metal is divided into two types: internal thread and external thread. The surface of the drum is also treated in various ways, such as rubber-coated to increase friction and prevent scratching of the workpiece, while galvanised or stainless steel is suitable for wet or corrosive environments.

For example, as you can see in the roller line below, the roller conveyor line is directly made of stainless steel rollers.

Two,Customised roller conveyor linesAcknowledgement requiredTechnical parameters:

The size of the object to be conveyed:This includes length, width and height to ensure that the roller pitch and diameter match the cargo.

Weight of the conveyor unit:Select the appropriate roller material and transmission method according to the load.

Condition of the bottom of the conveyor:The bottom of the cargo needs to be flat and rigid to avoid point or line contact that can cause damage to the drum.

Work environment requirements:If humidity, high temperatures or chemicals affect the roller, you need to choose a corrosion-resistant or high-temperature-resistant roller material.

Power forms:Unpowered rollers are suitable for manual push or inclined free fall, while powered rollers require a choice of sprockets, timing belts or drum motors depending on the transmission method.

III. RollingSelection of cylinder type

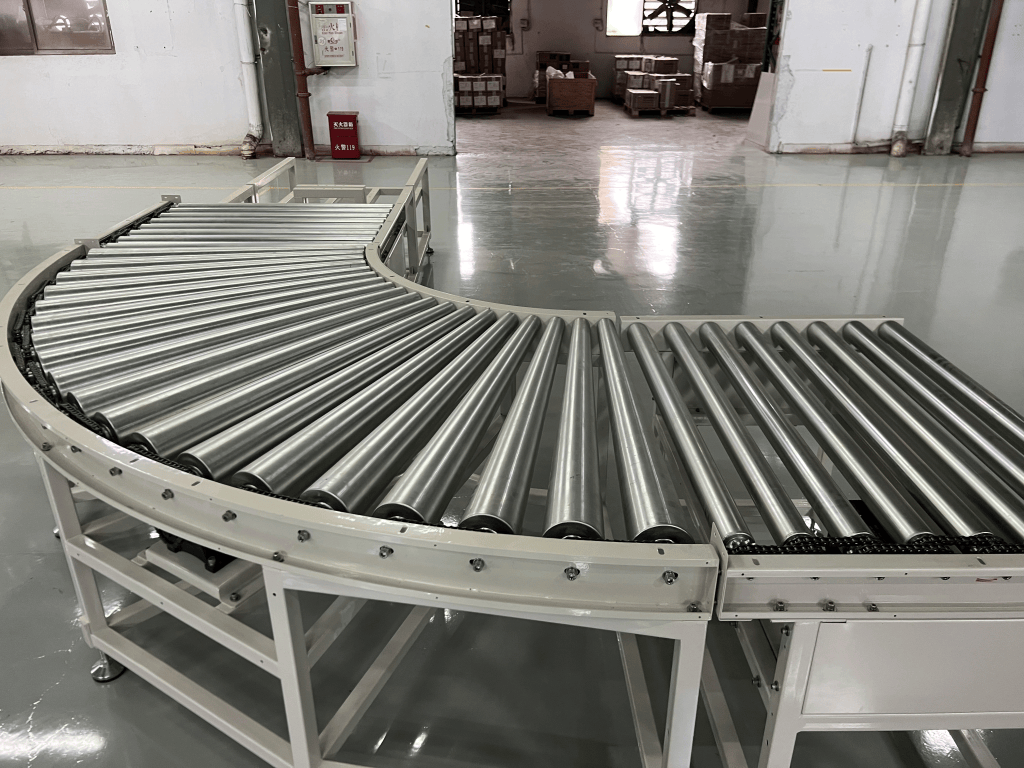

roller conveyorThere are various types of them, and it is vital to choose the right type of roller for your actual needs:

Unpowered roller:

Suitable for light load, short distance conveying, relying on manual push or inclined free slide.

Power Conveyor Roller:

Suitable for medium or high load scenarios, transmission methods include sprocket drive, synchronous belt drive, multi-wedge belt drive and so on.

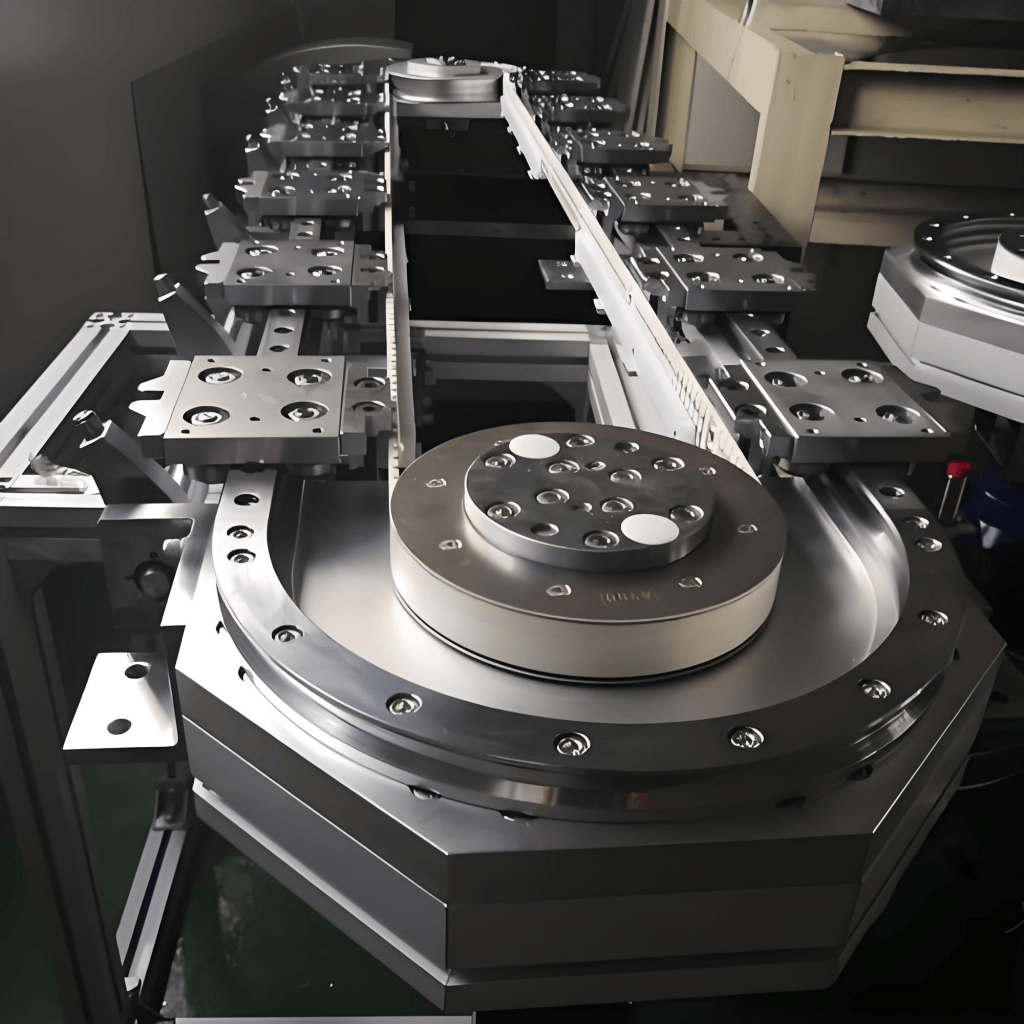

Motorised pulley:

Built-in motor for long distance and heavy duty conveying, easy to install and space saving.

Accumulation roller:

When goods need to be accumulated on the conveyor line, the sleeve accumulation type or adjustable accumulation roller can be selected.

Four,Application Industries

roller conveyorDue to its high efficiency and flexibility, it is widely used in the following industries:

Express Logistics:For crossbelt sorters with sorting efficiencies up to 10,000 pieces/hour.

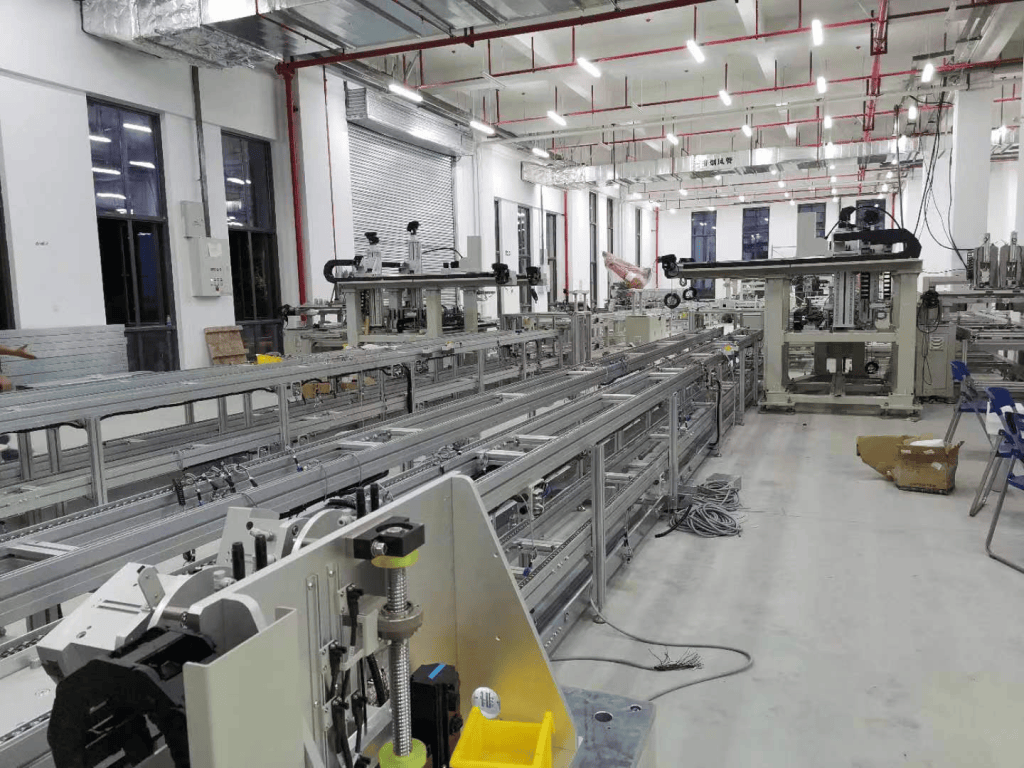

Automotive Manufacturing:Heavy-duty roller line conveying the car body with robotic welding.

Food and Drink:Stainless steel rollers are suitable for wet and chemically corrosive environments.

E-commerce warehousing:Dynamic weighing and automatic labelling stations are integrated to improve logistics efficiency.

Cold chain logistics:Stainless steel drum with anti-condensation design for low temperatures up to -25°C.

As an important part of industrial automation, the design and selection of roller conveyor lines need to take into account the characteristics of the material, conveying requirements and the working environment. Through a reasonable choice of roller type and transmission mode, can effectively improve production efficiency and equipment life. Standing in the mechanical engineer's point of view, it is recommended to pay attention to the material of the roller, load capacity and matching of the transmission system when selecting the type, in order to ensure the stability and reliability of the equipment in the actual application.