In modern logistics warehousing and production lines, roller conveyor line has become the preferred solution for material conveying by virtue of its flexibility, high efficiency and low cost. Whether it is courier sorting, factory assembly, or warehousing logistics, it can greatly improve the operational efficiency with the advantages of modular design + stable operation, so it has been one of the most commonly used equipment on the automated production line. So for the roller line, how much do you know?

I. Types of roller conveyor lines

roller conveyorIt can be categorised according to different characteristics, and if it is categorised according to the driving method, it can be classified into the following 3 types:

1. Unpowered roller lines

- Working principle: rely on gravity or manpower to promote the goods along the surface of the roller sliding

- Characteristics: simple structure, no energy supply, easy installation, low cost

- Applicable scenes: suitable for light load, short distance conveying, such as packaging workshop, loading and unloading area, etc.

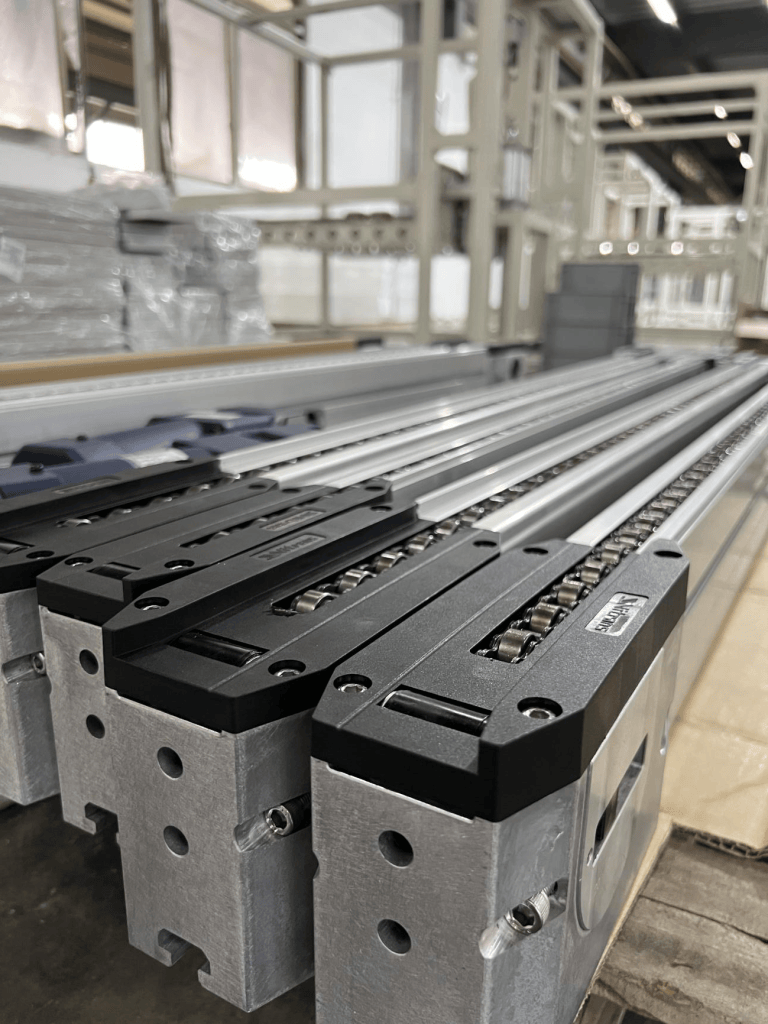

2. Power drum lines

- Working principle: driven by the motor drum rotation, through the friction to drive the goods to move, support frequency conversion speed control

- Characteristics: stable and controllable conveying speed, strong load capacity, can achieve automatic continuous conveying

- Scenario: suitable for automated assembly lines, such as courier sorting centres, automotive parts assembly lines, etc.

3. Stacking drum line

- Principle of work: add blocker and accumulation function on the basis of power roller line, which can store goods temporarily and realise beat control.

- Features: Buffer function to support stacked storage of goods

- Scenario: for production lines that need to balance the production beat, such as electronic assembly lines, food packaging lines

Second, the core advantages of roller conveyor line

1. Efficient and flexible transport capacity

- Wide range of speed adjustment: the conveying speed can be adjusted steplessly within the range of 0.5~30 metres/minute, accurately matching different production rhythms.

- Modular design and layout freedom: the standardised modules support a variety of layout modes such as straight line, turning and climbing (maximum slope ≤15°).

2. Low-cost maintenance and operations

- Simple and reliable structure: the drum line has a simple structure, fewer failure points and less routine maintenance.

- Convenient replacement of spare parts: Individual drums can be replaced individually, the maintenance process does not require large tools, and the maintenance time is short.

3. Broad compatibility

- Multiple carrier adaptability: Can convey boxes, trays, turnover baskets and other forms of carriers.

- Wide load range: single roller load range is 5~200kg, which meets the diversified conveying needs from light parts to heavy equipment.

4. Outstanding energy-saving and environmental performance

- Unpowered type with zero energy consumption: completely dependent on gravity or human power, no energy consumption.

- Powerful low-power design: the motor power is usually between 0.2 and 2.2kW, which, together with the high-efficiency transmission system, results in low energy consumption.

III. Typical application scenarios

1. Express logistics sorting centres

- E-commerce warehouses: for parcel sorting, packet conveying, efficiently handling large quantities of orders

- Express outlets: loading and unloading roller platforms for rapid loading and unloading of goods and temporary storage.

2. Manufacturing lines

- Automotive manufacturing plants: parts are transported to assembly stations and accurately aligned to production line beats.

- Home appliance manufacturing: Finished product packaging assembly line, stable delivery of home appliances, reducing manual intervention

3. Warehouse handling systems

- Three-dimensional warehouse: connecting shelves and workstations to automate goods in and out of the warehouse.

- Cold chain logistics: Stainless steel roller line for conveying frozen products, resistant to low temperatures and humid environments.

4. Customised applications for specific industries

- Food processing: food-grade 304 stainless steel rollers, in line with food hygiene and safety standards

- Electronic workshop: anti-static roller conveying PCB boards, effectively preventing static electricity damage

Fourth, roller conveyor line selection guide

1. Clarify load requirements

- Evaluation of the weight of a single piece: Selection of the appropriate size roller according to the weight of the single piece of the conveyed item.

- Planning of the total conveying capacity: combining the production beat with the conveying efficiency, determine theplatenThe total load capacity and conveying speed of the

2. Determining the transport environment

- Consideration of environmental factors: analyse the humidity, temperature, cleanliness and other environmental conditions at the conveying site, and select roller materials with special properties such as corrosion resistance, high temperature resistance or dust resistance.

3. Selection of drive type

- Unpowered solutions: for light loads, short distances and cost-sensitive scenarios.

- Power drive: Suitable for automated conveying scenarios with medium to long distances, high loads and stable speeds.

- Accumulation type selection: for production lines that require buffer and temporary storage functions.

4. Planning layout details

- Route planning: Determine whether the drum line requires functional modules such as straight lines, turns and climbs.

- Supporting equipment integration: Consider the docking requirements with other automation equipment to ensure the feasibility of system integration.

roller conveyorAs the "invisible backbone" of the automated production line, it is continuously empowering industrial upgrading with the advantages of flexibility, durability and low cost. It not only plays an important role in the traditional workshop, but also becomes more and more intelligent and efficient with the upgrading of automation and the application of intelligent technology. In the future, the roller conveyor line will develop in the direction of higher precision, higher speed and stronger intelligence, providing better logistics and conveying solutions for various industries. If you are looking for suitable conveying equipment for your production line or logistics system, roller conveyor line is undoubtedly a choice worth considering.