In modern industrial productionRing guideConveyor systems have become the choice of many automated production lines due to their high efficiency and precision. However, in the face of the market each has its own characteristics of the ring line, how to pick the most suitable one? Today we will bring you an in-depth understanding:

I. Classification of ring guide conveyor system

Ring guide conveyor systems can be divided into different categories based on a number of factors.

According to the shape of the line body, there are rectangular guide and elliptical guide; according to the installation mode, it is divided into horizontal and vertical installation; according to the transmission mode, chain drive, belt drive and linkage drive are common. In addition, according to the load characteristics and applications, it can also be divided into three types: high load / large pitch / long range type (≤ 50kg), light load / dust-free environment type (≤ 15kg), small pitch / vertical installation type (≤ 10kg). Different classifications are suitable for different production scenarios to meet diversified industrial needs.

Second, the ring guide rail conveying system selection points

Selection is the key to ensuring efficient operation of the conveyor system. The following is a detailed selection guide:

l Load Type

Define the load situation in production, including vertical load, radial load, bias torque, pressure loading force and so on. Different types of loads have different requirements for the design and material of the guide rail, accurately determine the type of load in order to ensure the stability of the system to carry.

l Number and spacing of workstations

The number of workstations directly determines the number of slides. At the same time, the centre distance between adjacent workstations needs to be accurately matched to the production beat, in order to achieve a smooth production process and avoid production congestion or idle conditions.

l transmission method

-Timing belt drive: suitable for light load and high speed scenarios, low cost and easy maintenance, but with limited load capacity. Its advantage is that it can achieve fast transmission under light load and improve productivity.

-Chain drive: suitable for heavy-duty, long lineal bodies, impact-resistant but with high maintenance costs. It can provide reliable transmission security in high load and long distance conveying tasks.

-Connecting rod drive: Suitable for high-speed medium load scenarios, with fixed distance between work stations and high precision. It can ensure the synchronisation between workstations and satisfy the production process which requires high precision.

l environmental adaptation

Consider the production environment of dust, humidity, corrosive media and other harsh factors to choose the right type of material. For example, in high humidity environments, corrosion-resistant materials are required to extend the service life of the guide.

l Supplier Screening

Priority is given to well-established manufacturers with independent production capacity and technical teams, such as Weitron. Avoid the trap of low price, you can verify their production equipment and quality inspection process through on-site inspection, and refer to their past cases, such as applications in semiconductor and new energy fields, to ensure the quality of the supplier's products and after-sales support.

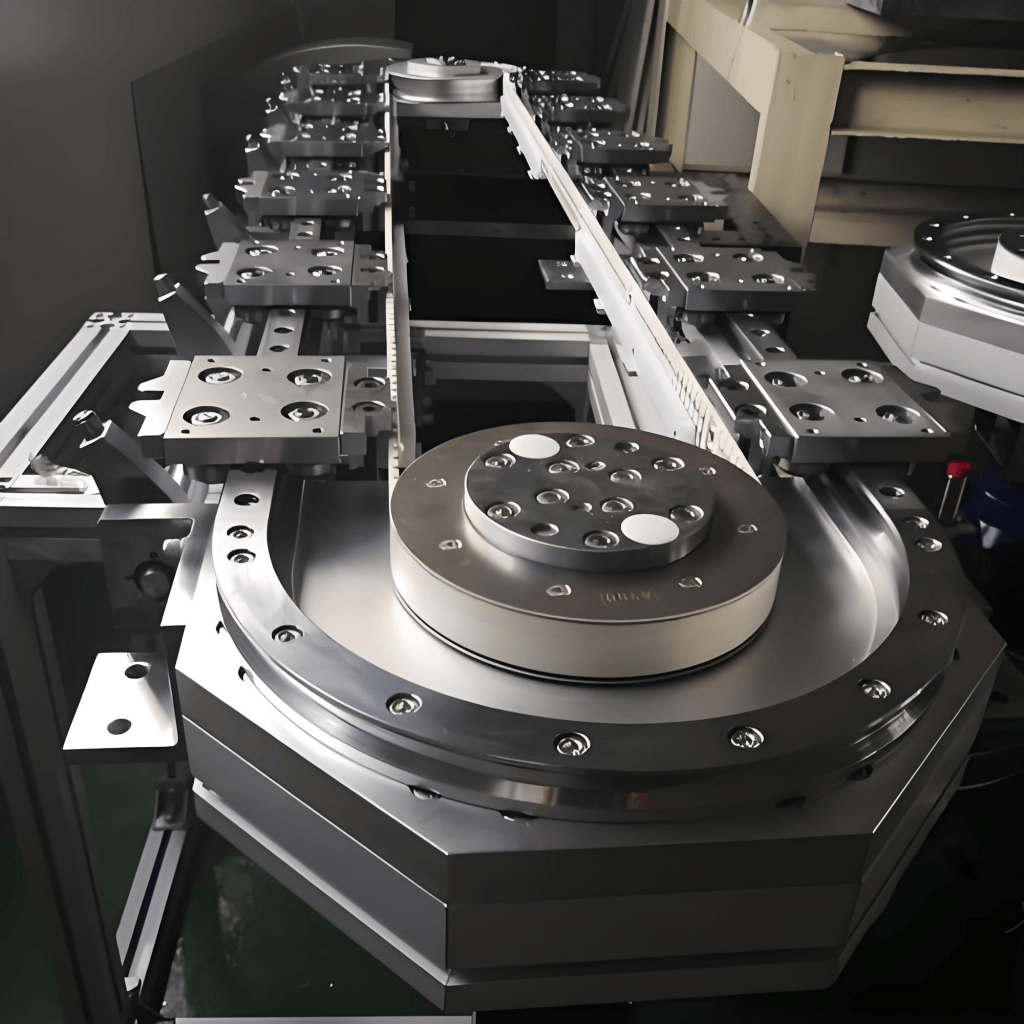

Advantages of Wei Chuang Ring Guide Conveyor System

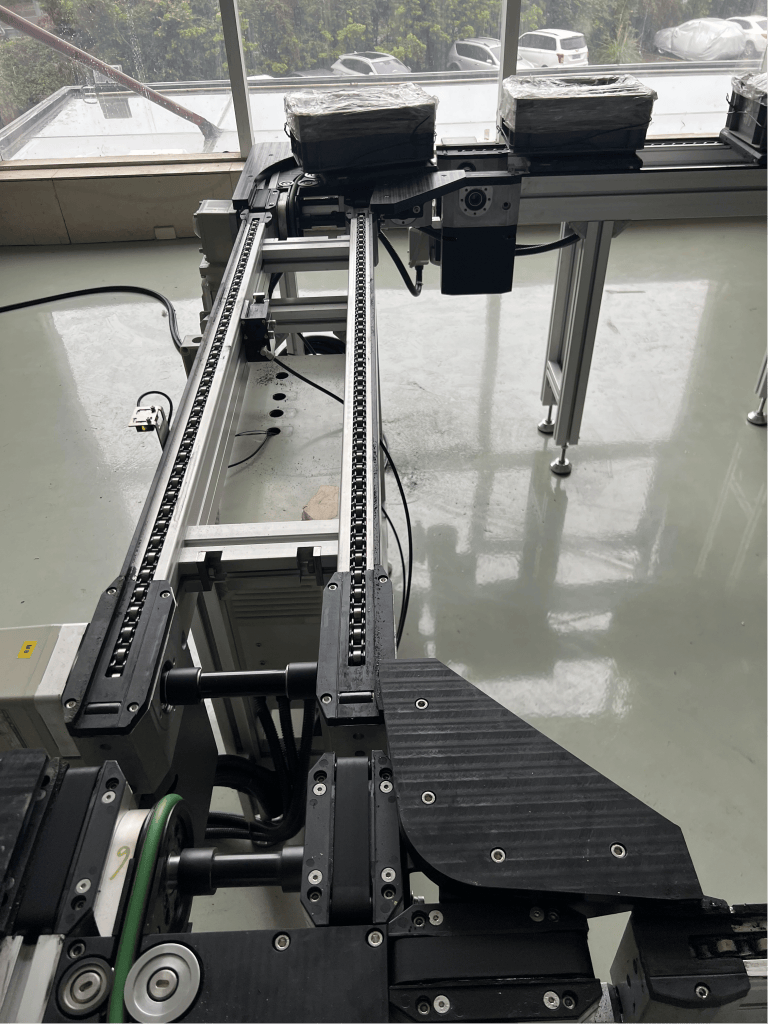

l [Belt-type - ring-guide conveyor system]

adoptiona leather drive beltIn terms of speed, the slider travelling time can reach ≥0.1s to ≥0.8s in light load scenarios, and the workstation switching time can be customised to ≤2s (including cylinder positioning time).

This system is suitable for light load (≤15kg), dust-free environment demand scenarios, such as 3C electronics, food and pharmaceutical industries, as well as scenarios that require low noise and flexible transmission, like precision instrument assembly lines. It has a high degree of automation, supports modular control, and can be integrated with electronic control systems and dust-proof mechanisms to provide efficient and clean transmission solutions for production.

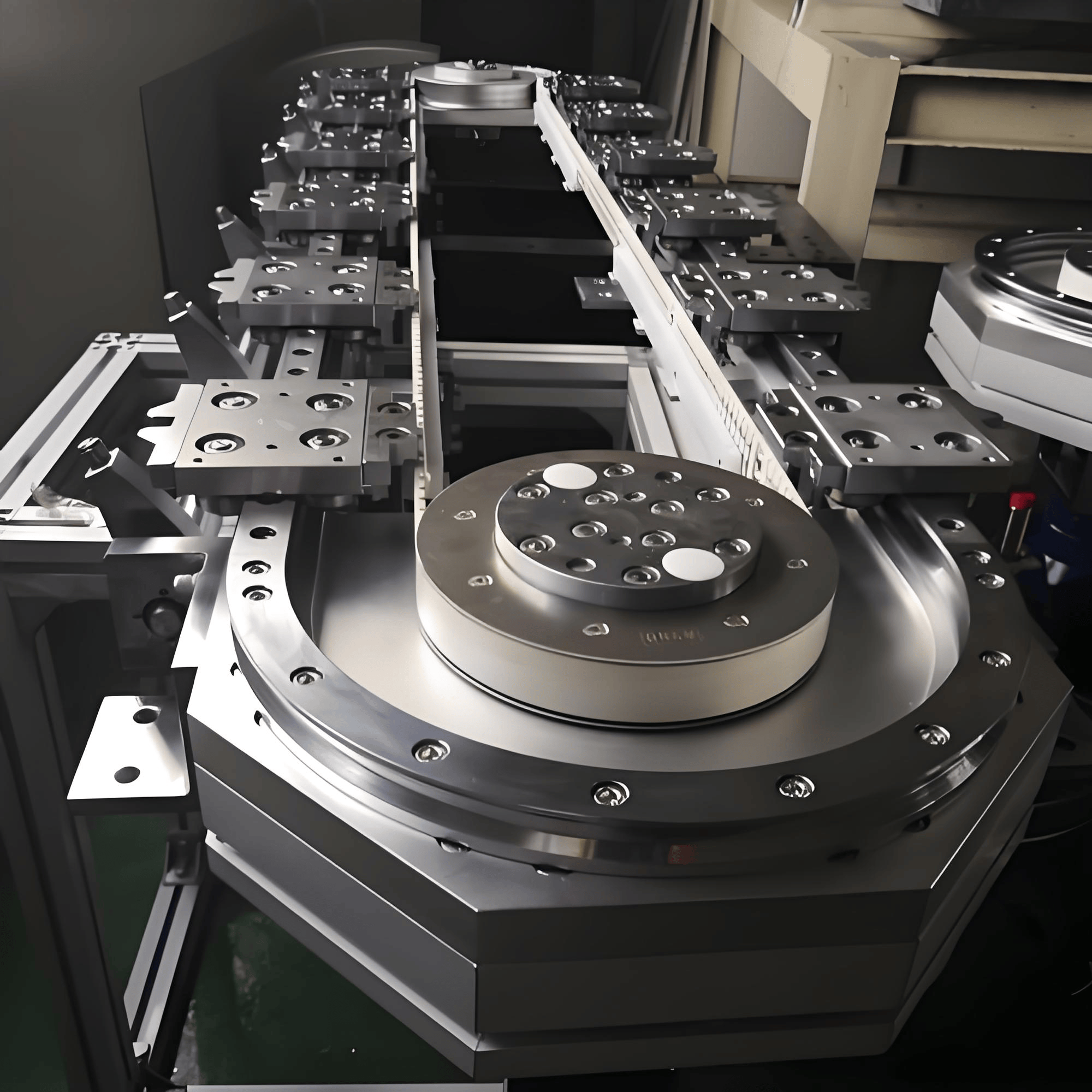

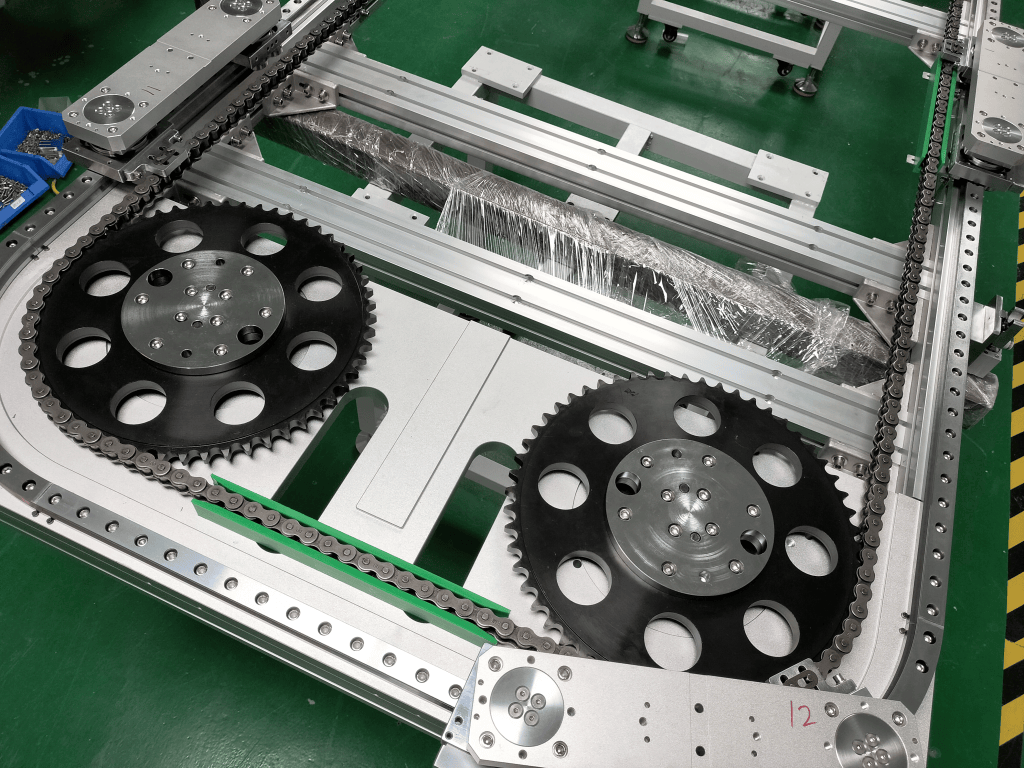

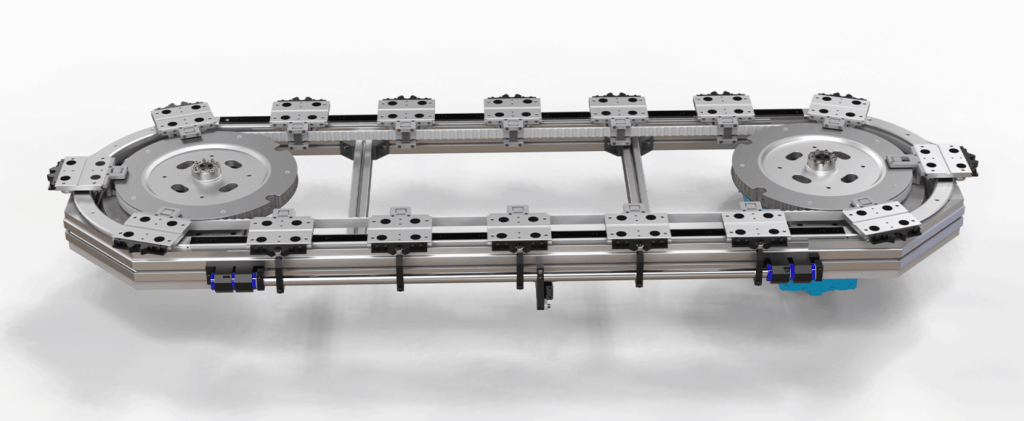

l [Chain type - ring guide conveyor system]

according tochain driveFor the driving mode, the slider moving time is generally in the range of ≥0.3s to ≥0.8s according to the load size, and the workstation switching time is ≤2s (including mechanical positioning time).

It is suitable for high load (≤50kg), long distance working stations, such as automotive engine parts conveying, as well as scenarios with high requirements for stability and high load capacity, such as home appliance spraying lines and heavy equipment assembly. The system supports multi-station synchronous control and can be equipped with positioning cylinders to ensure the accuracy and stability of the production process.

l [Connecting rod type - ring guide conveyor system]

utiliserod driveThe movement time of the slider is ≥0.5s to ≥0.8s, suitable for low and medium speed scenes, and the workstation switching time is ≤2s (including mechanical synchronisation time).

Suitable for medium loads (≤30kg), scenarios requiring high-precision synchronised positioning, such as battery component assembly, and scenarios requiring high mechanical rigidity and repeatable positioning accuracy, such as photovoltaic equipment assembly. It can be integrated with servo control system to realise multi-station high-precision synchronisation to meet the demand of precision production.

In conclusion.Ring guideThe selection of conveyor system needs to be considered by a combination of factors. Among many manufacturers, Weitron, with its rich product line and excellent quality, provides customised and efficient conveying solutions for customers in different industries, helping to improve production efficiency and quality, and promoting the development of industrial automation.