In modern industrial production, belt conveyor is an indispensable material conveying equipment. Belt conveyor can be divided into belt conveyor and synchronous belt conveyor according to the form of conveyor belt, in which the belt conveyor is relatively more widely used. The following is an article to introduce the two conveyors, so that you have a more in-depth understanding:

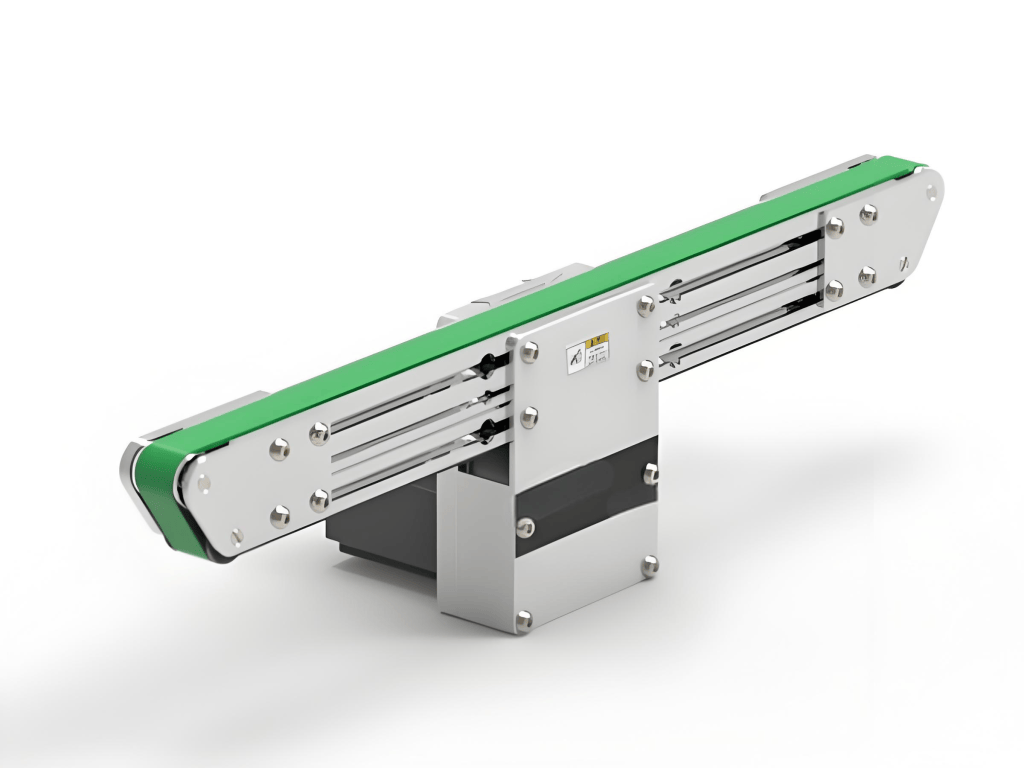

I. Belt Conveyor

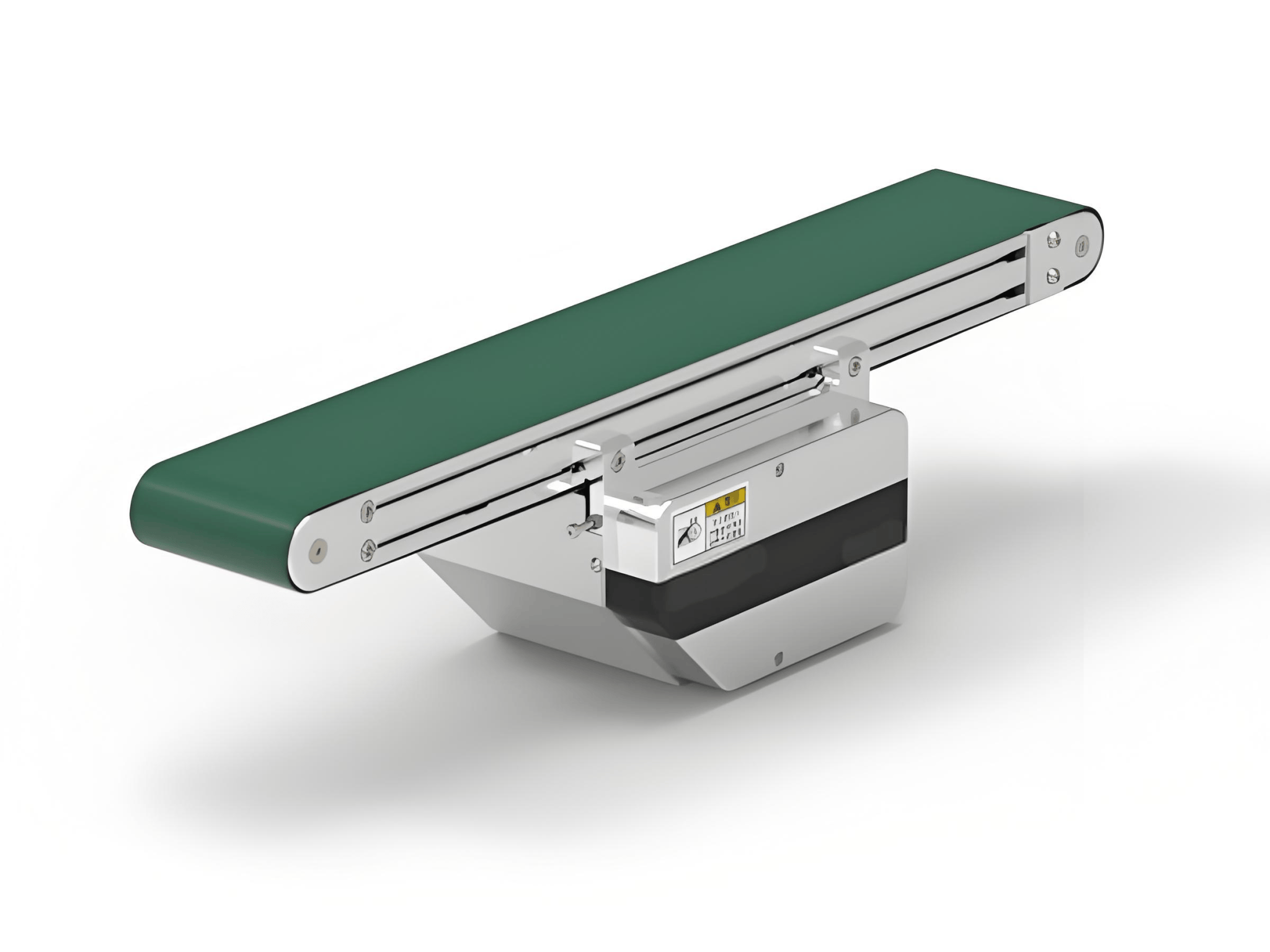

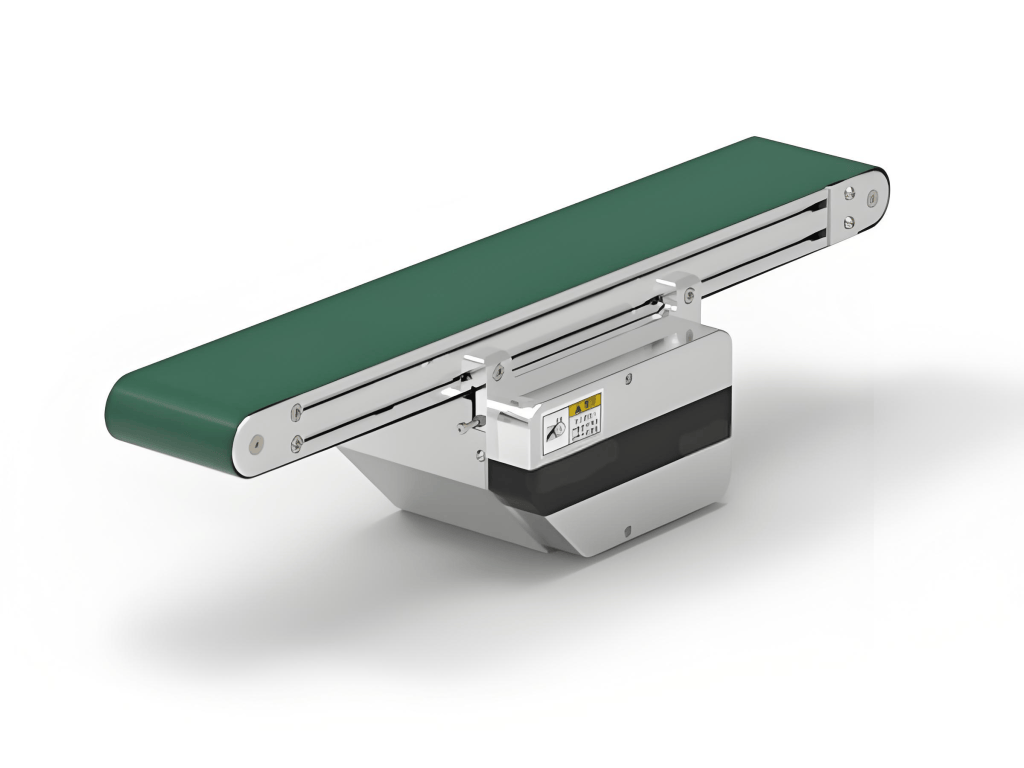

belt conveyorIt is a kind of commonly used material conveying equipment, which drives the conveyor belt movement through the transmission roller, so as to convey materials from one location to another. With its simple structure and easy maintenance, it is widely used in various industries such as home appliances, electronics, electrical appliances, machinery, plastic injection moulding, printing, food, etc., for the assembly, testing, debugging, packaging and transport of objects.

1、Working Principle

belt conveyorAccording to the principle of friction transmission, the driving roller drives the ring conveyor belt to run, and the friction between the conveyor belt and the material achieves the continuous conveying of the material.

2,Belt Conveyor'scentreStructure composition

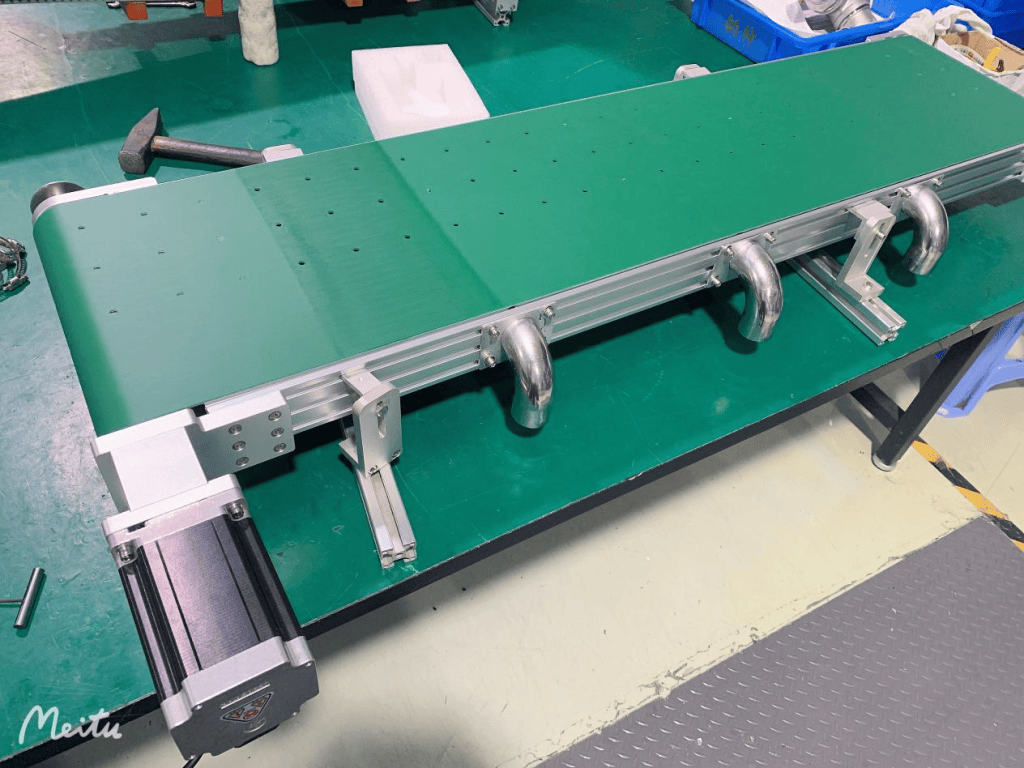

Main structural components: conveyor belt, rollers, drums, pallets, rollers, driving device, tensioning device, frame, etc.

(Using Wei Chuang products as an example)

-Conveyor belts: PU (abrasion and oil resistant), PVC (corrosion resistant), food grade PE (FDA compliant) and other options are available.

-Drive system: Standard with Taito/JSCC motors, support servo motor upgrade.

-Tensioning device: automatic tensioning device monitors the belt tension in real time, reducing the frequency of manual maintenance.

-Auxiliary components: polymer wear strips on the edges to reduce belt deflection loss.

-Guardrail and baffle: optional small C guardrail, jacking traverse mechanism, to achieve material diversion, positioning and other complex functions.

3,Belt Conveyor Features

-Simple structure: composed of conveyor belt, rollers, driving device, tensioning device and other parts.

-Wide range of applications: can be used in a variety of production environments

-Easy maintenance: only the rollers need to be repaired frequently, and the belts need to be replaced.

-Saving manpower: simple operation, easy maintenance, saving operating costs

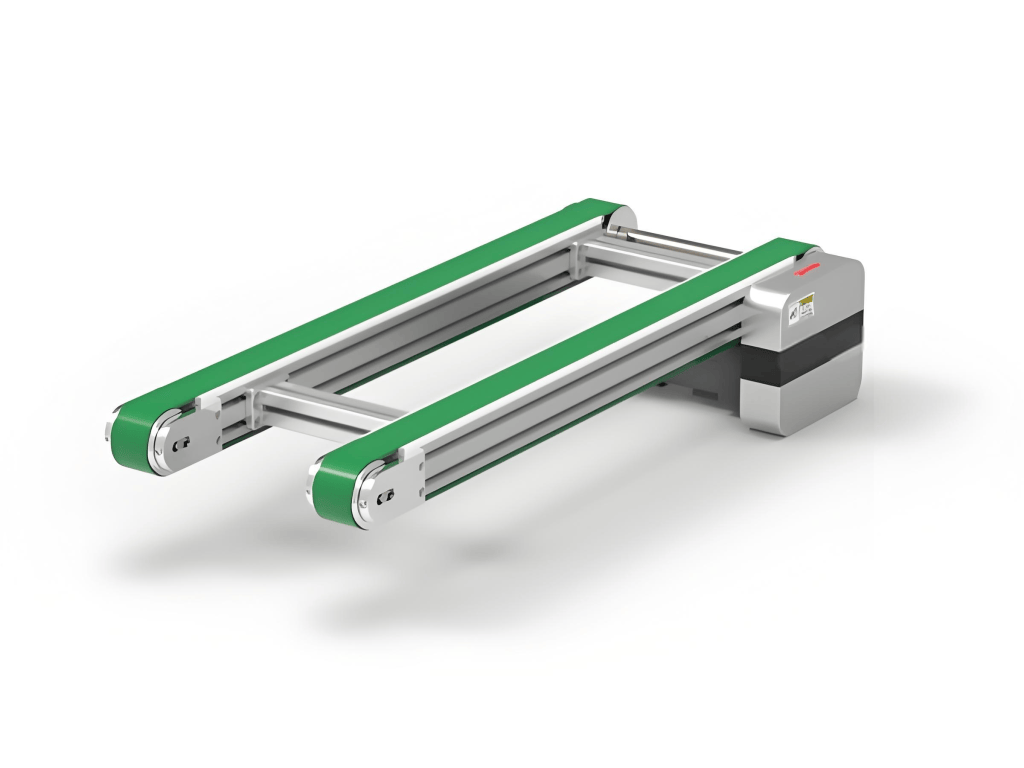

Two,Synchronous belt conveyor

Synchronous belt conveyorIt belongs to a new type of synchronous belt conveyor drive system. It is mainly used for positioning conveying, fixed distance conveying and transferring motion machinery. It is widely used in medical equipment transport, paper industry, tobacco manufacturing transport and automatic doors.

1、Working Principle

The teeth of the timing belt and the teeth of the timing belt pulley mesh with each other to transfer motion and power to achieve the conveyor function.

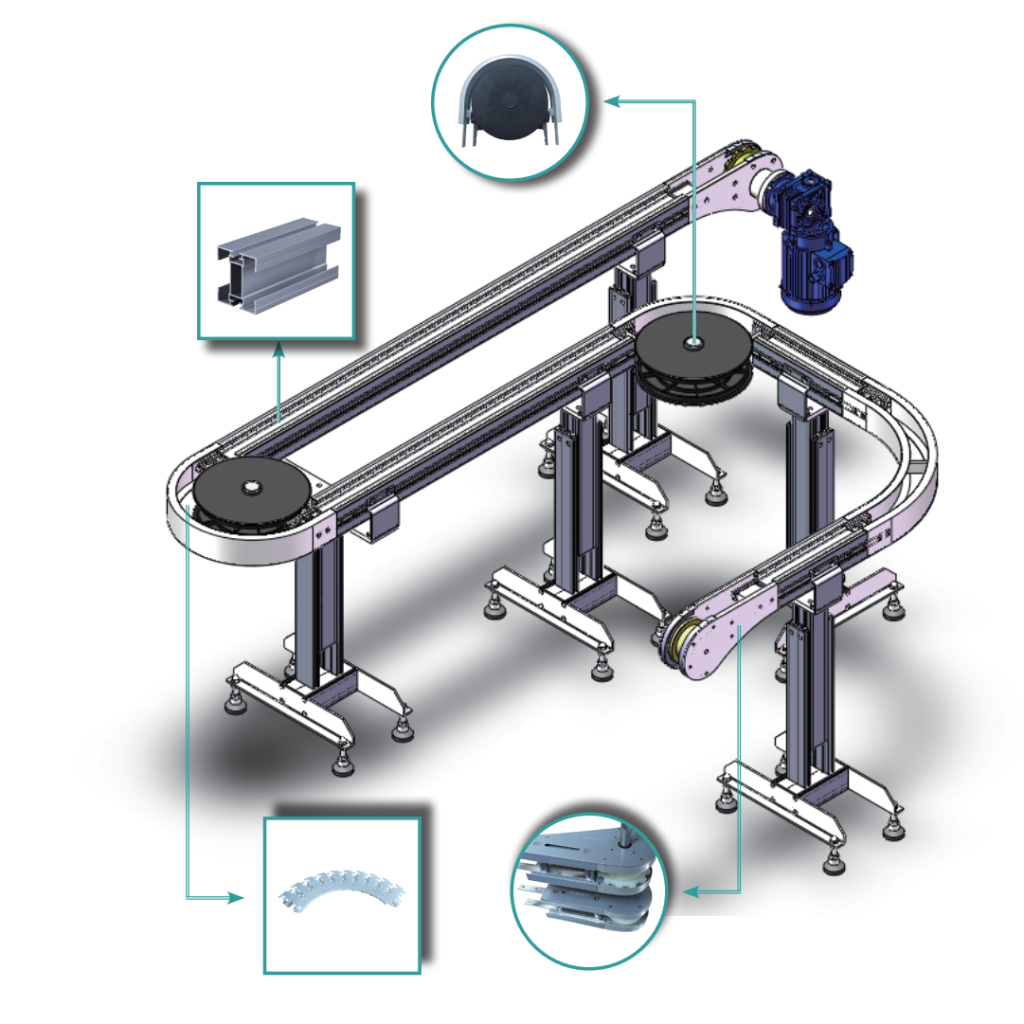

2、Timing beltStructural components of the conveyor

The structure consists of an annular synchronous belt with equidistant teeth on the inner peripheral surface and a synchronous pulley with the same teeth.

3、Timing beltConveyor Features

-Accurate conveyance: due to the meshing drive of the synchronous belt, it ensures precise conveyance without slipping.

-Good adaptability: according to the characteristics of the conveyor to adjust the synchronous belt width, pulley diameter and other parameters, to adapt to the complex layout of multiple lines side by side or connected.

-Strong customisation: can be customised according to the needs of different industries to meet diversified application requirements

belt conveyorand synchronous belt conveyor have their own advantages in industrial production. With the continuous progress of technology, these two types of conveyors will continue to be optimised and upgraded, injecting new vitality into the field of industrial conveying and helping the production process to be smoother. Whether your industry is the traditional manufacturing industry or the emerging automation field, choose the right conveyor equipment can effectively improve production efficiency and material flow speed. I hope this article can help you better understand the belt conveyor and synchronous belt conveyor, for your production process optimisation to provide reference.