In modern industrial production, the demand for flexible production is growing, and how to achieve flexible adjustment and efficient operation of the production line has become the focus of attention of enterprises. As a modular conveyor designed for heavy-duty scenarios, the accumulating roller conveyor line is becoming the preferred solution for many industries, such as automotive manufacturing, e-commerce logistics, food and beverage, etc., by virtue of its unique performance advantages. Follow along with(reddish jade)The pace of the world's most important conveyor, to understand exactly where the core value of the accumulation of roller conveyor equipment.

One,Modular design

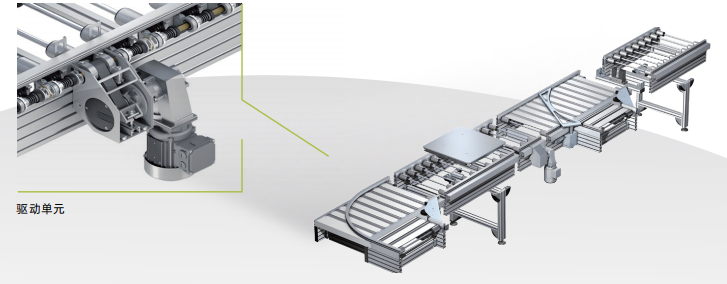

Accumulation roller conveyor lineAdopting highly integrated modular design, the core components include drive module, drum section, rotating unit, lifting unit, positioning unit, etc.. All components are pre-assembled and can be quickly combined through standardised interfaces, supporting complex layouts such as bi-directional shunting and multi-station docking.

- Rapid deployment::The system can be set up in as little as 1 day without complex commissioning, saving 70% of installation time compared to traditional conveyor lines.

- On-demand expansion:Modules can be added or subtracted flexibly according to production needs, for example, adding a new diverter to achieve multi-line sorting, or adding a rotary table to change the direction of the pallet, so as to easily adapt to the adjustment of the product line.

- Spatial optimisation:The drive unit is integrated underneath the conveyor surface, saving the 30% floor space and making it particularly suitable for plant environments with restricted floor heights.

Two,Heavy Duty Performance

For the heavy load requirements in industrial scenarios, WeiChuangAccumulation roller conveyor lineDemonstrates excellent carrying capacity:

- Strong carrying capacity:The maximum load of a single set of rollers is 200kg, and the whole line can convey up to 4000kg of heavy objects (such as car chassis and large equipment racks), which is suitable for heavy industry scenarios.

- Accurate accumulation and release control:Adopting bevel gear spindle drive technology, when the pallet is stacked, the roller and sprocket can be separated and idling, avoiding the goods extrusion damage. Accumulation force can be manually adjusted, and the repetition positioning accuracy reaches ±0.3mm, which ensures the safety of transporting precision components.

- Low Maintenance Advantage:Bevel gear drives eliminate the need for frequent lubrication and reduce maintenance costs by 50% compared to traditional chain drives, and operate at less than 60dB, improving the workshop environment.

Three,functional integration--Creating Intelligent Production Lines

Accumulation roller conveyor lineIt does not operate independently, but builds a full process automation system by linking with peripheral equipment:

- Ejector positioning unit:When the pallet reaches the designated work station, the double cylinder lifting device will lift the pallet 5mm away from the conveying surface, with the horizontal stopper to achieve accurate positioning, supporting a maximum of 1200 x 1200mm pallet, suitable for assembly, testing and other processes.

- Heavy duty traverse unit:With three-phase motor drive, it can pan the pallet transversely to the vertical conveying line, change the conveying direction, support the maximum load of 1.5kg/cm, and realise multi-line linkage.

- Rotary table unit:Servo-driven 90°/180° swivelling, with 270° range adjustment in stages and a minimum swivelling time of 4 seconds, ensures that the pallet is always orientated in the same way and adapts to the layout of the cycle line.

Four,Application Scenario: Multi-industry Adaptation

(reddish jade)Accumulation roller conveyor lineScale applications have been realised in a number of areas:

Automotive Manufacturing:It carries the body chassis on the assembly line and completes 90° steering with the rotary table, supporting the production of multi-vehicle mixed lines; the accumulation function avoids the congestion of assembly stations and improves the flexibility of the production line.

E-commerce logistics:Sorting link through the splitter to achieve automatic parcel lane, handling more than 200 pieces per minute, accumulation function supports dynamic cache, reducing manual intervention.

Food and Drink:In the glass bottle filling line, the roller runs smoothly at low speed to avoid collision of bottles when accumulating and placing; the jacking and positioning unit accurately connects with the labelling and cartoning equipment to improve the efficiency by 40%.

Five,Accumulation roller lineSelection Guide for

Weitron offers standardised products and personalised services with the following core parameters:

- Roller parameters:The material is stainless steel, the pitch is optional 130/195/260mm, the conveying width 300-1200mm, the length of the line 1000-6000mm.

- Drive Configuration:Support 220V/380V voltage, motor can choose Sumitomo, Seiken, Siemens and other brands, power 750W, conveying speed up to 15m/min.

- Customised services:Provide non-standard dimensions, special materials (such as corrosion-resistant coatings), explosion-proof design and other customised solutions to meet the needs of special scenarios such as chemical and pharmaceutical industries.

Order example: TS7-BG1-B500-L4000-P130-V12-JY075-380 (Double track roller line, width 500mm, length 4000mm, pitch 130mm, speed 12m/min, Seiken motor, 380V)

About Us

Focusing on the research, development, manufacturing and sales of intelligent conveying equipment, WeiChuang Automation is committed to providing efficient, safe and reliable conveying solutions for the automation market. And we provide a full range of pre-sales consulting and after-sales support to provide users with the best experience.