In modern logistics and production environments, efficient and energy-saving conveying equipment has become a key factor for enterprises to improve production efficiency and reduce operating costs. The logistics equipment we show you today is one of the most commonly used conveyor lines in the conveying industry - theroller conveyorThe machine is a very powerful logistics equipment, which can be used in a wide range of applications. Through in-depth analysis of its working principle, features, advantages and use scenarios, we can more fully understand the superior performance of this logistics equipment.

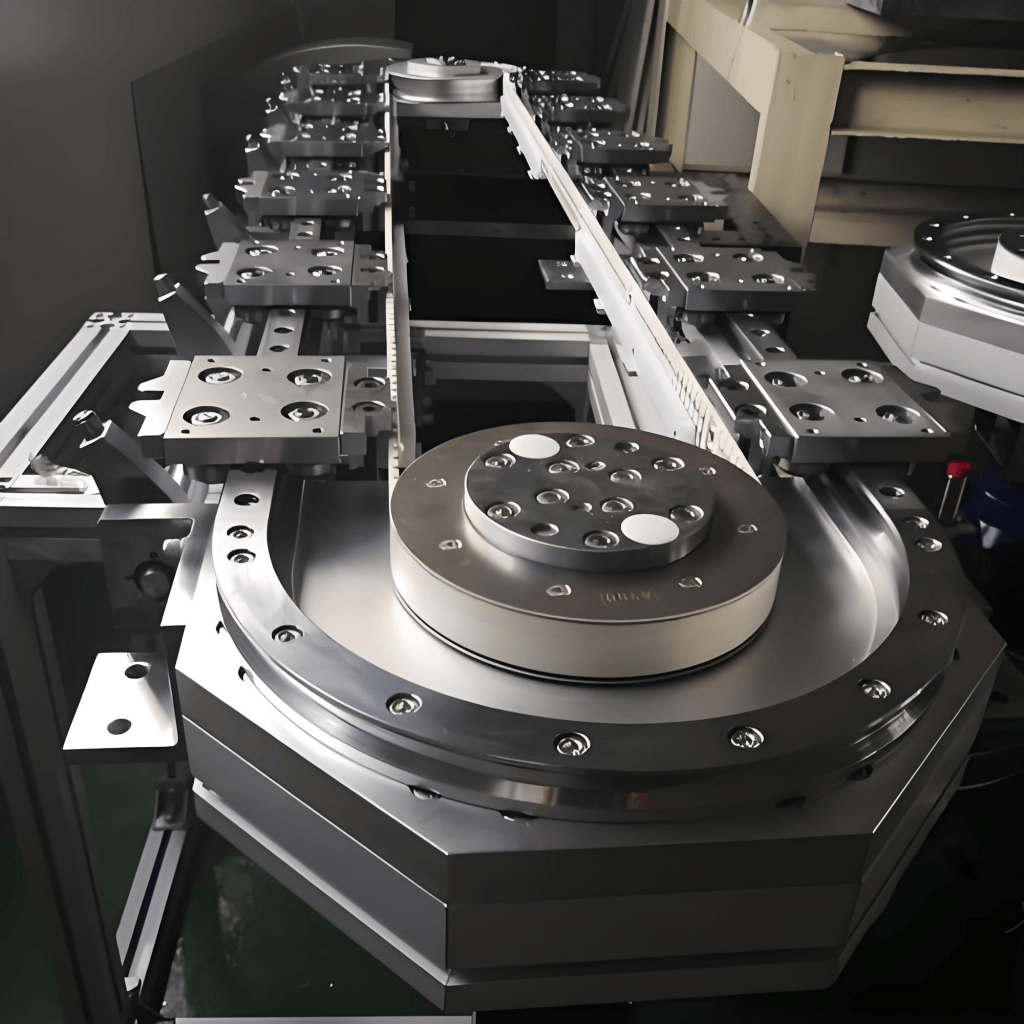

I. Types and Configurations of Roller Conveyor Lines

Roller conveyor lines cover a wide range of types to meet the needs of different customers:

- Conveyor line type: non-power roller conveyor line, power roller conveyor line, accumulation roller conveyor line

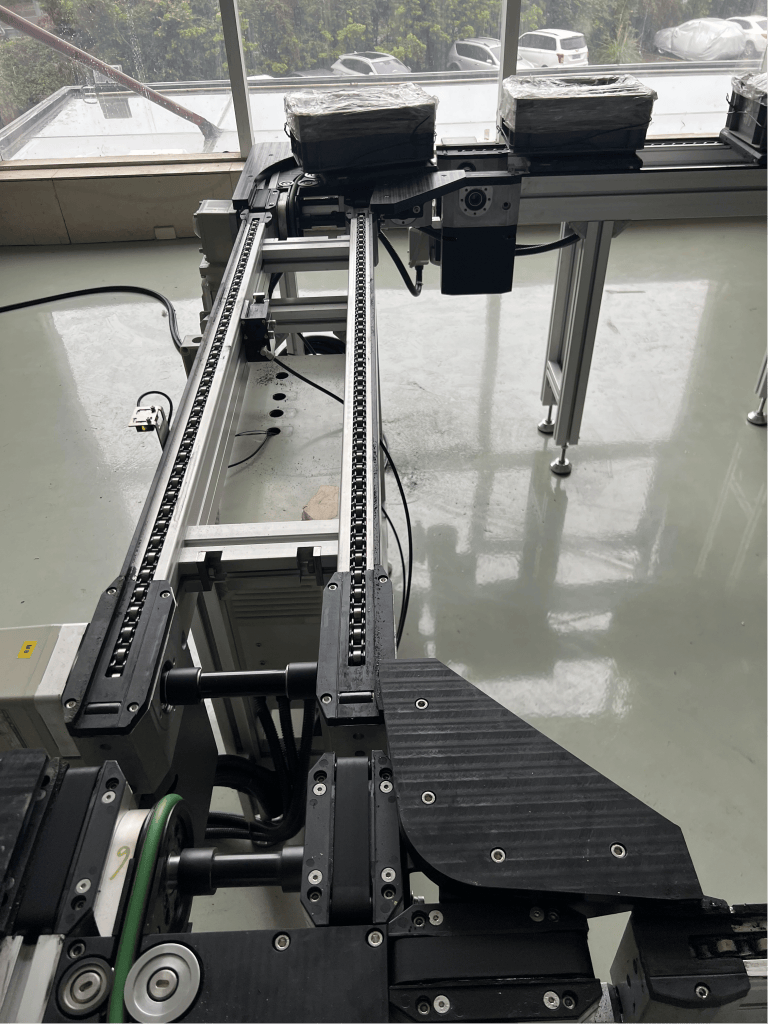

- Drive mode: drum motor drive and motor reducer drive

- Conveying speed: fixed speed and speed control (electronic speed control, frequency control and mechanical speed control) two kinds of

- Line form: straight, curved, slope, three-dimensional, telescopic and multi-fork road, etc.

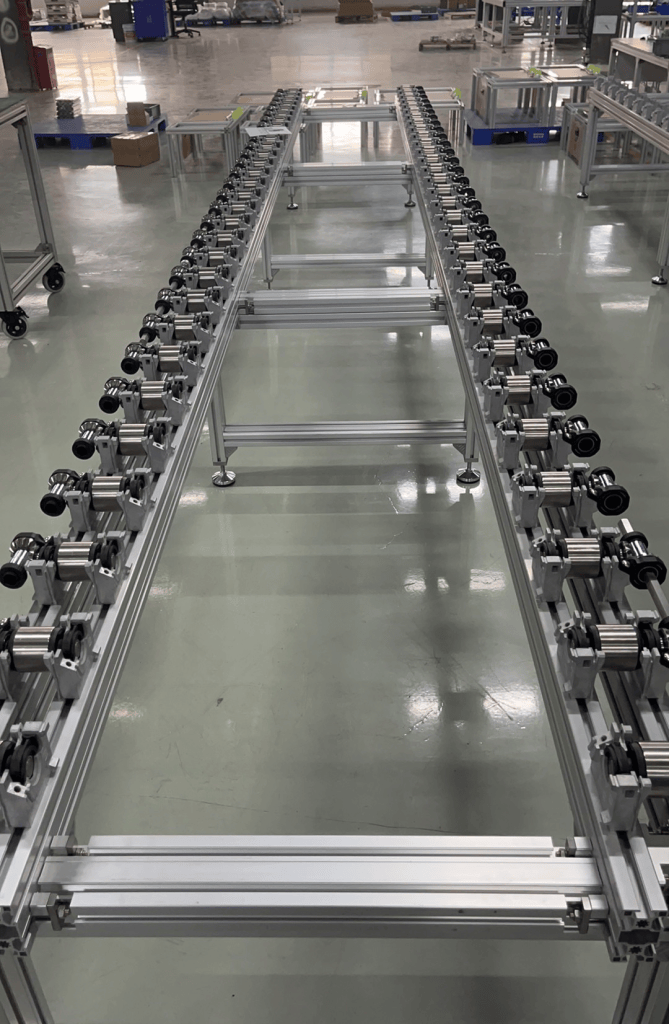

- Roller material: stainless steel, engineering plastics, aluminium alloy, carbon steel

- Surface treatment of rollers: galvanised, chrome-plated, cast rubber, thermoplastic, polyurethane.

- Rack material: stainless steel, aluminium profile, carbon steel (general surface plastic spraying, painting, baking paint treatment)

- Accessories and supporting auxiliary devices: optional according to the customer's actual application

Second, the working principle of roller conveyor line

The working principle of roller conveyor line is simple and efficient, it consists of a series of parallel arranged rollers to form a continuous conveyor system, through the rotary movement of the rollers, so as to achieve efficient and stable transfer of goods.

Third, the characteristics of roller conveyor line

roller conveyorIt has the characteristics of simple and reliable, easy to use and maintain. It can not only meet the needs of the system of object detection, diversion, packaging, etc., and complete many aspects of the process requirements, but also can use the accumulation roller to achieve the stacking of materials conveyance, which greatly improves the flexibility and efficiency of the production line.

Fourth, the 4 advantages of roller conveyor line

-Efficiency gains:Roller conveyor lines are capable of achieving continuous and stable transfer of items, significantly increasing production efficiency.

-Cost reduction:Effective reduction of operating costs through optimisation of production line layout and reduction of manual operations.

-Flexible in use:Supports a wide range of types, configurations and speed options for flexible response to various production needs.

-Wide range of applications:It is suitable for conveying all kinds of cartons, bags, pallets and other pieces of goods, as well as electronics, home appliances, new energy and many other industries.

Fifth, the use of roller conveyor line scene

Weichuang Automation's roller conveyor lines are widely used in all kinds of logistics and production scenarios.

In the courier sorting centre, the roller conveyor line can quickly and accurately distribute parcels; in the e-commerce warehouse, it helps the efficient operation of the order picking line; in the cold chain logistics, it ensures the stability and safety of the pallet transport. In addition, in the field of electronic manufacturing, home appliance finished product packaging, new energy battery module automation production line, roller conveyor line also plays an irreplaceable role.

concluding remarks

From traditional manufacturing to smart factories.roller conveyorAlways plays a key role. With Industry 4.0, all types of conveying equipment are continuing to evolve towards greater intelligence and efficiency. Choosing the right roller conveyor solution will bring significant efficiency gains and cost optimisation to your business.

Wei Chuang Automation Conveyor

Wei Chuang has more than 10 years of experience in the research and development of conveyor equipment manufacturing and customised conveyor production line, long-term commitment to the production and processing of automated assembly line equipment, sales, to provide users with high-quality, professional material handling systems and standardised one-stop purchasing services, so that customers can experience a professional and caring selection and procurement process.

Our products include conveyor equipment and conveyor accessories, which are widely used in various fields such as new energy, 3C electronics, shoe-making and automobile manufacturing.