I. Introduction

hoist(Elevator Conveyor)It's through the hopper,leather beltmaybesprocketsIt is the equipment that continuously lifts materials from a low place to a high place by the load-bearing mechanism. It can stably convey bulk materials, boxed goods, etc. on vertical or inclined paths, and is widely used in factories, warehouses, mines and other scenarios to solve the problems of low space utilisation and vertical conveying bottlenecks.

Second, the type of hoist

There are 3 main types of hoists if you divide them according to the principle of operation:

1.Bucket elevator

Features: Vertical lifting by hopper loading materials, suitable for coal, cement, grain and other bulk materials (temperature ≤ 250 ℃).

Advantage: compact structure, high conveying efficiency, especially suitable for continuous vertical transport of granular/powder materials, used in mining, building materials and other industries.

2.Belt elevator

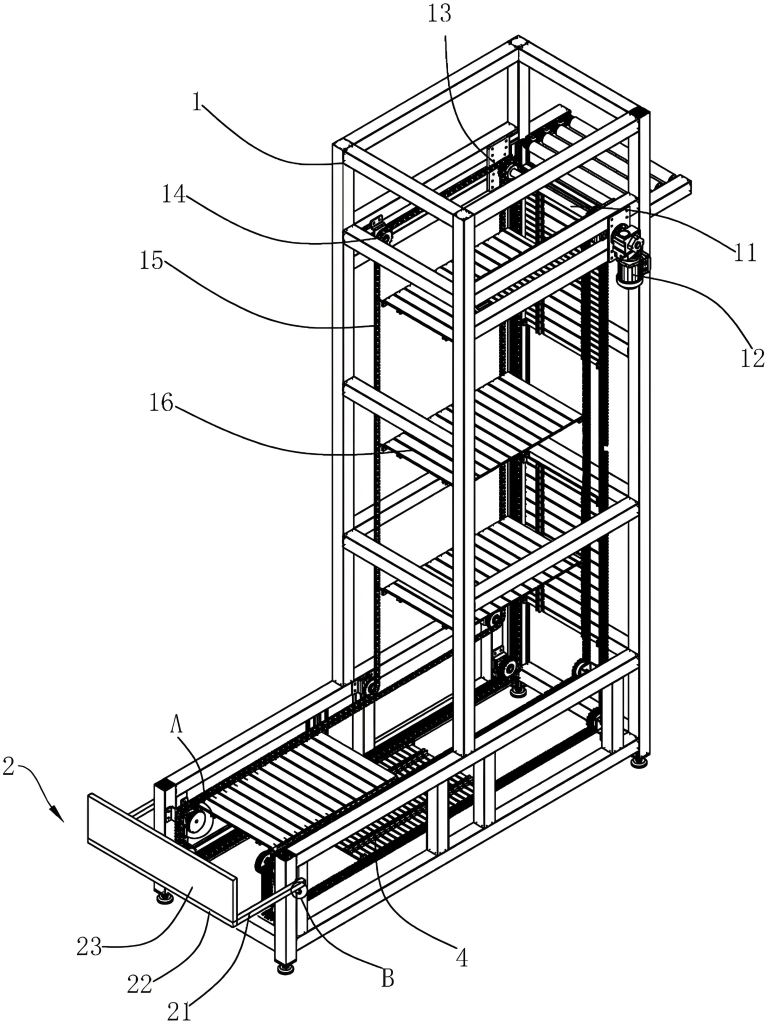

Characteristics: Lifting of the material by means of the movement of the rubber belt / wire rope belt.synchronous beltType can be combined with pallets to formRing conveyor systems.

Advantage: large conveying capacity, smooth operation, simple structure, commonly used in automated production lines, to achieve the material in the multi-layer space of the cycle of conveying.

3.Chain Elevator

Features: With high strength chain as the traction member, it is suitable for conveying heavy materials such as ores and mechanical parts.

Advantage: Strong abrasion resistance and high bearing capacity, indispensable in mining, heavy machinery manufacturing and other scenes that require high strength.

Three, six core advantages, redefine the vertical transport

- Small footprint: Only a few square metres of floor space is required, making vertical space more efficient and saving over 70% of floor space compared to ramp conveying.

- High efficiency: continuous operation without stopping, far more than manual handling.

- Strong adaptability: resistant to dust, high temperature and humidity, stable operation in harsh environments such as mine shafts and open-air construction sites.

- Intelligent: Equipped with control system, it can accurately adjust the speed and position the unloading to avoid material loss.

- More energy-saving: Vertical lifting reduces friction loss compared with slope transport, and some models are equipped with frequency conversion technology, which reduces energy consumption.

- Easy Integration: Seamlessly connecting production lines, AGVs, and warehousing systems, it becomes an important piece of the puzzle in the logistics chain of smart factories.

IV. Which scenarios are most neededhoist?

Factory floor:Connecting multiple levels of production lines for rapid transfer of components, such as cross-level transport of engines in automotive plants.

Building materials construction site: lifting cement, gravel and other heavy materials, solving the problem of transporting materials in high-rise buildings.

Mining:Vertical transport of ore from underground to surface to cope with large loads and harsh environmental demands.

Logistics warehousing:Realise automatic inter-floor transfer of parcels and boxes to improve the efficiency of warehousing and sorting.

V. Future upgrades::technology-enabled

1. Digital twins

By simulating the operation of the equipment through 3D modelling, installation problems can be detected in advance, reducing the time for commissioning the 80% on site and lowering project costs.

2. Green energy efficiency

The innovative design converts the kinetic energy of falling materials into electrical energy, which is fed back to the grid or used by the equipment for its own purposes, further reducing energy consumption and practising low-carbon production.

3. AI Synergy

Linkage with AGV and robotic arm, automatic planning of conveyor path according to real-time data, to achieve the whole process from sorting, lifting to storage unmanned, to create an intelligent three-dimensional logistics system.

Six,summaries

hoistIt is the equipment that is just needed for the tight space and high traffic scene. However, care needs to be taken to choose the right scene in order to give full play to the maximum value of the lifting machine. When choosing, the priority is based onMaterial characteristics (bulk / heavy / light), environmental requirements (temperature / dust / humidity) and automation needsMatch the bucket,Belt or chainMachine type. In the future, with the digital twin, AI and other technologies landing, the lifting machine will be upgraded from a "mechanical porter" to an "intelligent logistics hub", bringing more efficient vertical conveying solutions for industrial production and warehousing logistics.

Is your factory still worried about conveying materials up and down? Maybe a hoist might be the "space saver" you need!