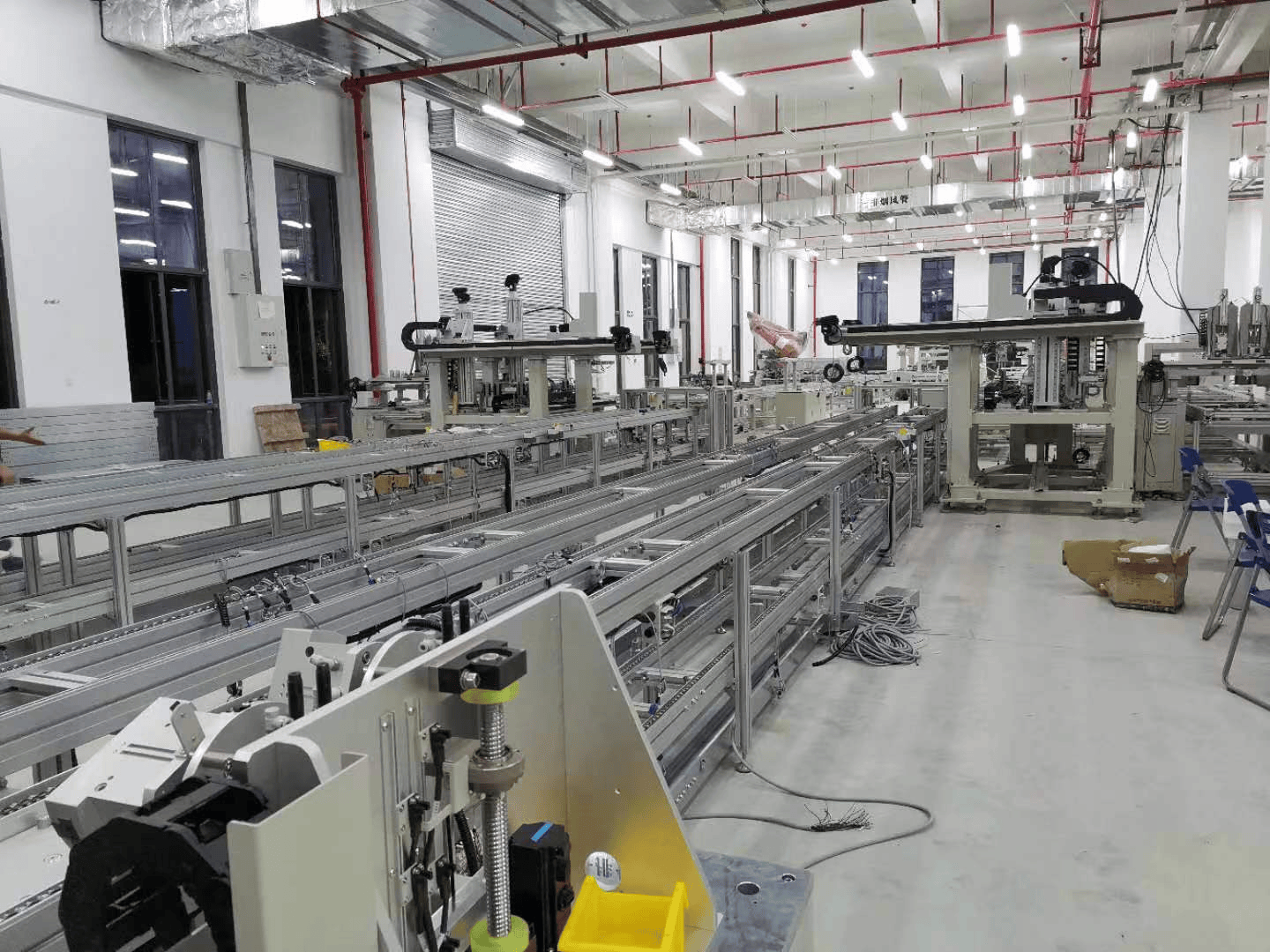

In the production layout of modern factories, an efficient material conveying system is like the blood circulation of human body, which is the "lifeline" to maintain efficient production. Today, let's focus on the speed multiplier chain conveyor line, especially the single speed multiplier chain series, to see how it injects strong power for enterprise production.

One,What is a Speed Chain Conveyor Line?

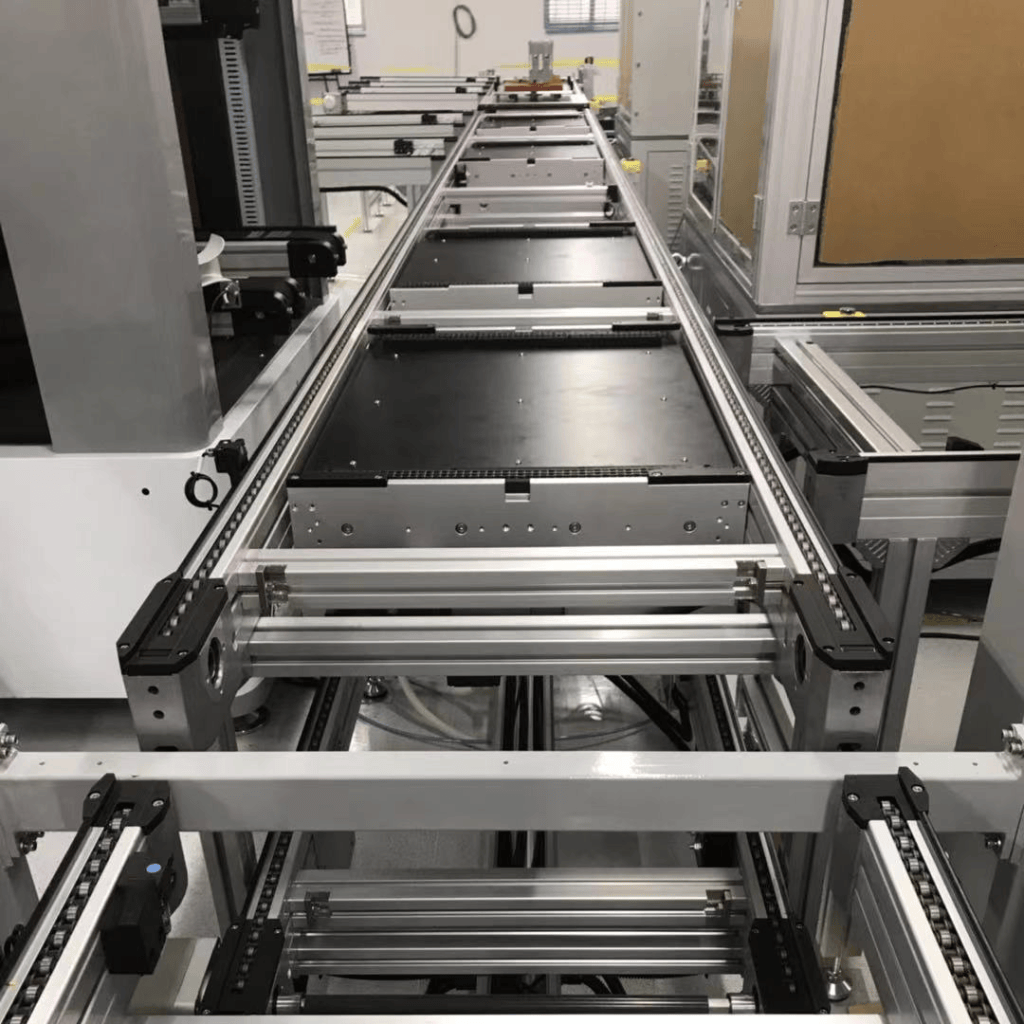

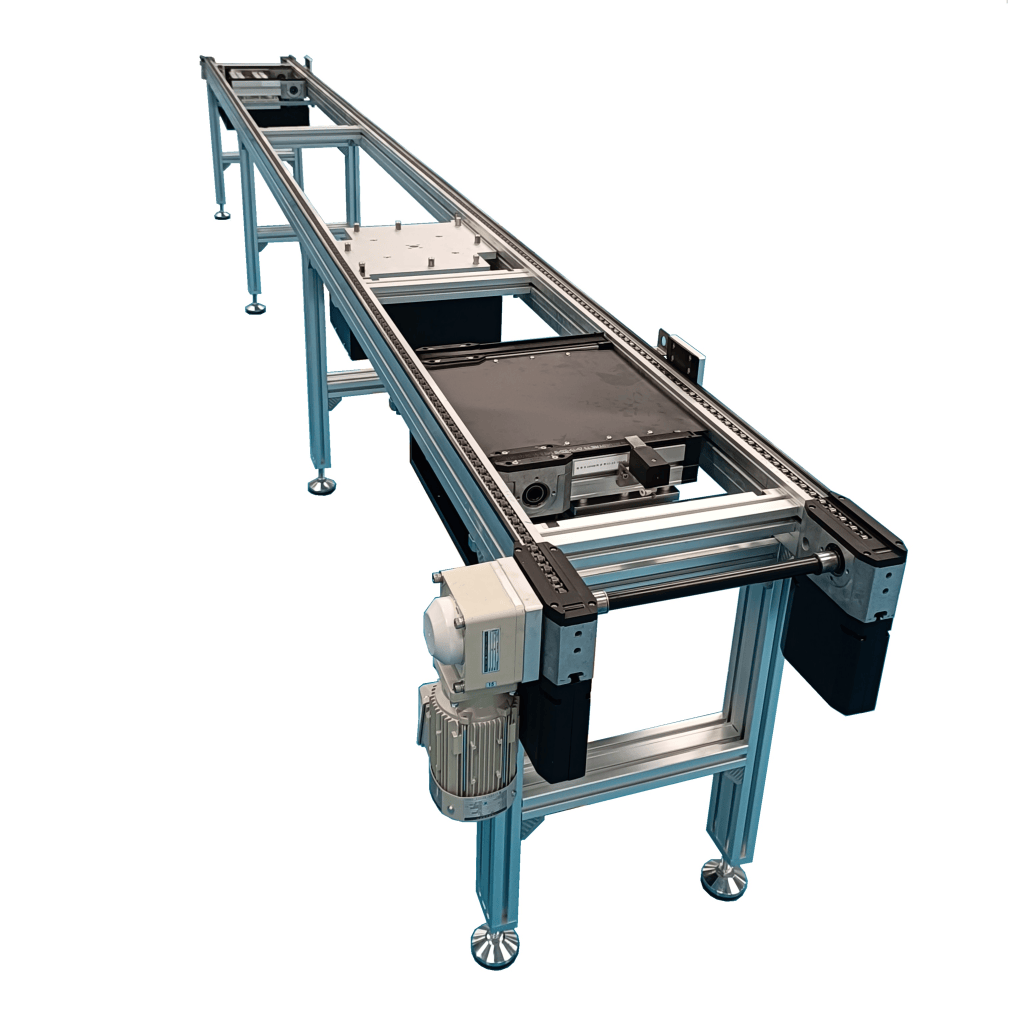

Speed Chain Conveyor LineThe conveyor line, also known as speed chain conveyor, is a kind of automated equipment widely used in assembly halls, covering a variety of types such as triple speed, 2.5 times speed and single speed. This kind of conveyor line is often called assembly line or assembly line, which plays a vital role in industrial production. The chain conveyor line takes the work plate as the carrier, and through the up and down, left and right reciprocating motion of the chain, it drives the products to be conveyed efficiently between different work stations, so as to realise the automation and beatification of the production process.

Two,Configuration parameters

| Line width | Can be flexibly customised to suit different sizes of products and tooling boards. |

| Line Height | Typically set at 750mm, the overall height ranges from 500-1000mm and can be adjusted to suit the layout. |

| Line length | Single-stage drive up to 25m (optional) |

| Conveying speed | 2-20 metres/minute |

| Chain form | Adoption of single speed multiplier chain, through the design of incremental speed increase, to achieve the speed difference between the chain and the workpiece plate |

| Types of Workplates | According to the product characteristics and process requirements, such as anti-static, high strength, etc., the workpiece can be divided into a variety of types |

| Frame Material | High-quality steel as frame material |

| Using the power supply | 220V/50HZ or 380V /50HZ |

Three,core component

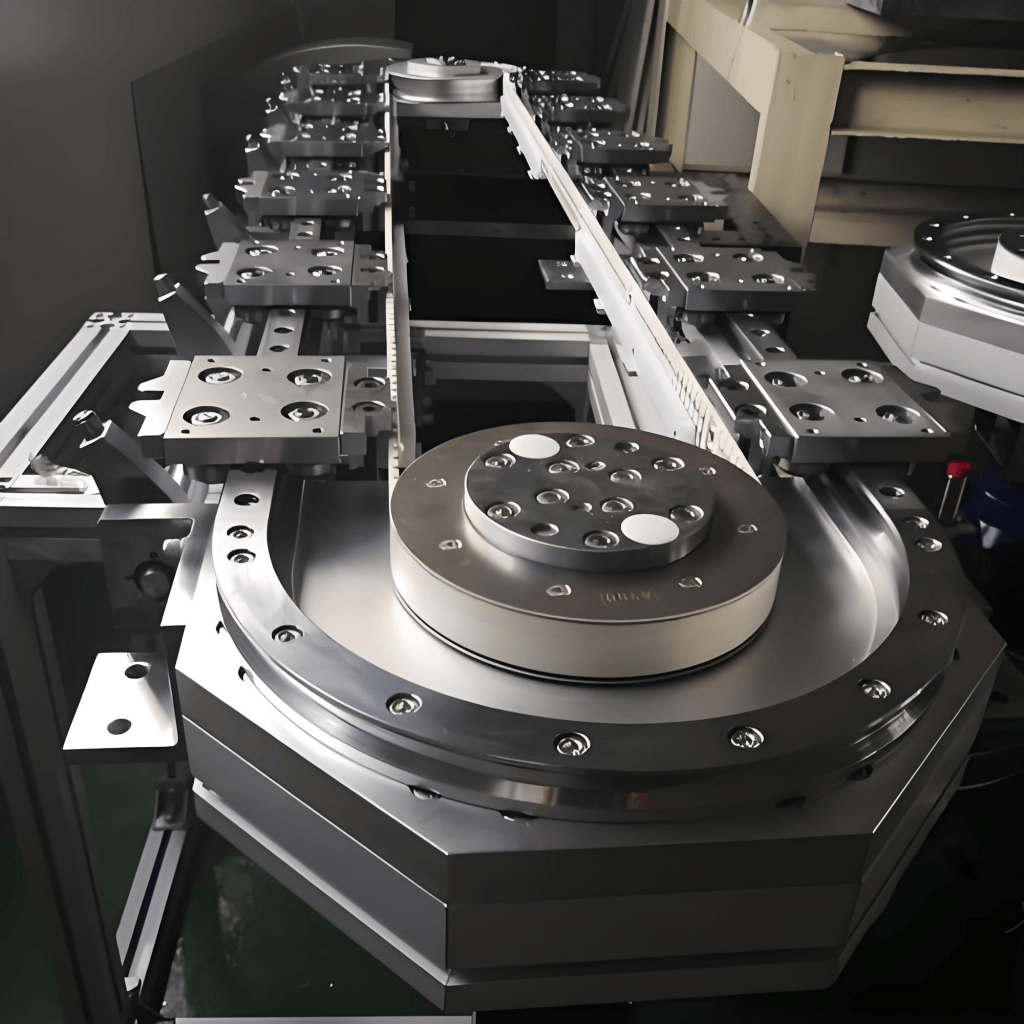

- Multiplier chain: core speed increasing component, adopts high strength steel, the surface is treated with wear-resistant, ensuring long-term operation without jamming, with precision guide rail, to achieve smooth and high-speed conveying of workpiece plate.

- Blocker: Pneumatic/electrical dual optional, supports precise positioning and flexible blocking, can be linked with PLC system to achieve automatic stop and release of workpiece at the designated station, with error control within ±0.5mm.

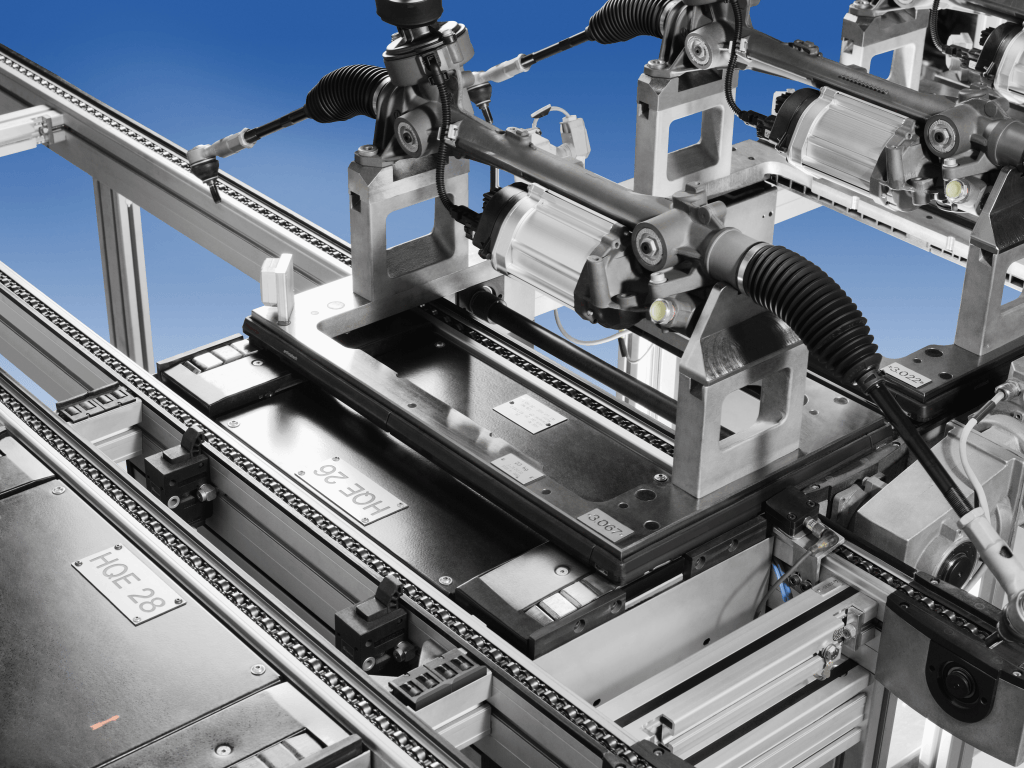

- Workpiece pallets: WA2/WE2 high-strength pallets are fitted as standard, with customised PA/PE abrasion-resistant pads and maximum loads of up to 240kg per pallet.

- Drive system: independent three-phase geared motor drive, support 220/380V AC power supply, can be configured with frequency converter to achieve stepless speed regulation, motor protection level IP65, to adapt to dusty, humid and other complex environments.

- Support unit: 4560 light duty outriggers or 4590 heavy duty outriggers with base brackets to ensure line stability, with a maximum spacing of 2000mm to save floor space.

Four,Core benefits

1. Replacement of manpower: 24 hours continuous operation, single hour conveying capacity of up to 5-10 times the traditional manpower, and bid farewell to the "manpower handling slow, errors and omissions" of the pain point.

2. Heavy load: Maximum load for a single section of wire is 2200kg.Stacked roller chains(medium), engines, gearboxes and other heavy parts can also be transported smoothly, breaking through the limits of human handling.

3. Precise positioning: the stopper and positioning pin sleeve can achieve ±0.05mm precision positioning, reduce manual alignment errors, and improve assembly precision and yield rate.

4. Reliable operation: automatic chain tension adjustment, motor overload protection, anti-static design, with wear-resistant strips and self-lubricating kit to reduce maintenance frequency.

5. Wide range of applications: from new energy battery PACK line, 3C electronics assembly to hardware parts inspection, supporting horizontal circulation, vertical lifting and other layouts, compatible with multi-station synchronous operation.

6. Flexible customisation: the size of the work plate, the height of the line, and the electrified settings (e.g. lighting, sockets) can all be customised as required, and modules such as jacking rotation and bend switching can also be integrated.

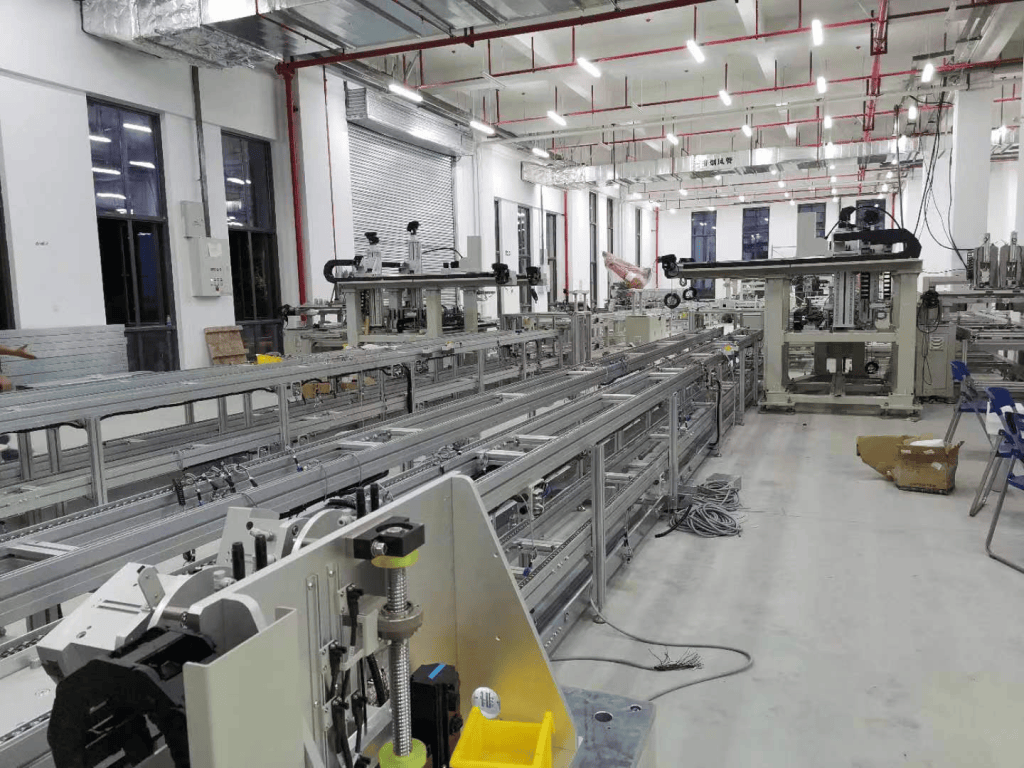

Five,application scenario

Wei Chuang'sSpeed Chain Conveyor LineIt has successfully empowered multiple industries:

New Energy / Lithium-ion:Battery module assembly and PACK line inspection, supporting anti-static trays and high-precision positioning to meet the stringent requirements of battery cell assembly.

3C Electronics:Mobile phone / computer machine assembly, parts inspection, flexible to adapt to the rapid flow of small-sized workpieces and multi-station co-ordination.

Auto Parts:Engine and gearbox assembly, heavy-duty design to easily cope with hundred kilograms of parts, with the hoist to achieve multi-layer line body linkage.

Instrumentation:Precision device assembly, anti-static, low vibration design, guarding the stability of sensitive components.

(reddish jade)Customised servicesThe choice is "Smart" for the future.

The style, length, height and width of the chain conveyor line, as well as the parameters and components such as work plates, can be customised according to the customer's actual production requirements. Whether it is a large-scale automated production line or a small assembly bench, we can provide the perfect solution. In addition, we can also add lamps, shelves, workstations and other auxiliary devices to the multiplier chain according to the customer's special needs, creating an integrated production work platform to meet the diverse needs of different production scenarios.

In today's world of escalating labour costs and fierce competition for production capacity, an efficient conveyor line is the "invisible production line" of an enterprise. With the core advantages of "high loading, high precision and high flexibility", Wei Chuang's pallet conveying system helps every customer to achieve efficient production and layout.