One,conveying line(used form a nominal expression)customisationusualThe following steps are included:

01

firstlydemand analysis

According to the production process, material characteristics (such as shape, weight, etc.), the production environment (space, temperature, humidity, etc.) to determine the type of conveyor line, size, load-bearing and functional requirements.

02

Design and Drawing

Analyse the effect that the customer wants to achieve according to the demand, and then design the drawings in detail, including the overall layout, structural dimensions, the way of assembling parts and the connection method, and clarify the driving method, the beat and the special function (e.g. turning, climbing, etc.).

03

makingsselection

Confirm with customers the profile specifications, types of fittings, connection methods, etc., to ensure the feasibility and economy of the design scheme.

04

working (of machinery)fit together

Machining and manufacturing according to the drawing pattern, the assembled parts must pass the quality inspection.

05

Transport and Installation

Send the conveyor line to the shipping area for packing, mostly using bulk shipment to reduce cost. Prepare the list and drawings, installation needs to be strictly in accordance with the drawings and specifications to ensure that the components are firmly connected and run smoothly.

06

Commissioning and acceptance

After the conveyor line arrives at the customer's site, the technicians will carry out no-load and load debugging after the installation is completed, mainly checking the running speed, stability, noise, vibration and other indicators to ensure that the conveyor line meets the design requirements. It will be put into use after acceptance.

The customisation process should be communicated with the supplier at all times to facilitate timely adjustment of the programme and ensure that the conveyor line is perfectly matched to the production process.

II. Case sharing

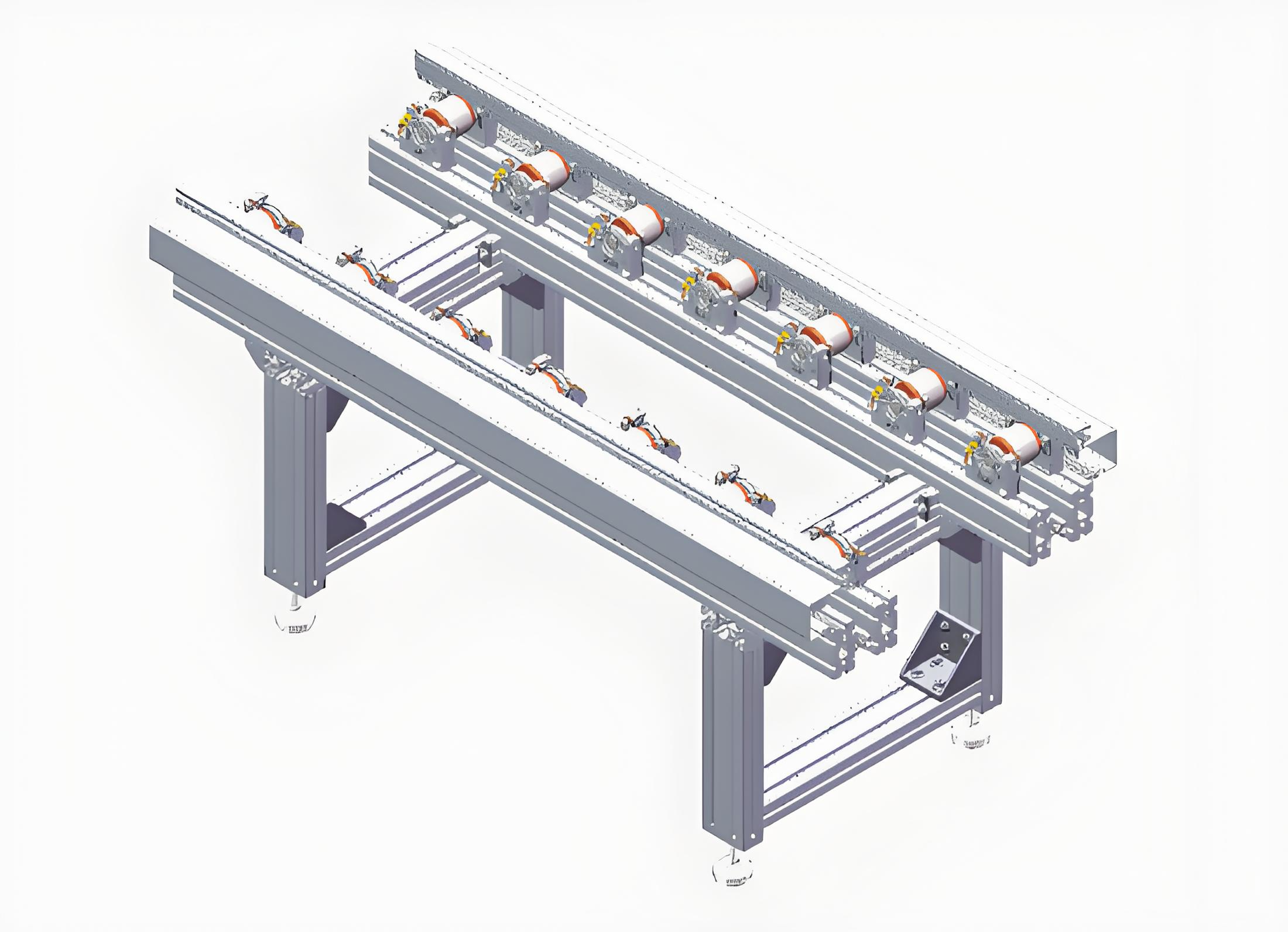

customisationpalletsdoubled speed chainconveying line.

Independent three-phase geared motor drive, supports forward and reverse operation, meets anti-static requirements. After full load performance test, 24 hours normal operation without wear and tear. Chain adopts steel stackingroller chainThe pallet is a WE2 conveyor pallet with a load capacity of up to 240kg, special PA wear pads with universal steel load plates and excellent load capacity. Under full load, a single section can be loaded with up to 2200kg without any problem. Pallet stacking and caching is also possible, and pallet widths of 60, 240, 320, 400, 480, 640 and 800 mm are available, and various specifications support non-standard customisation.

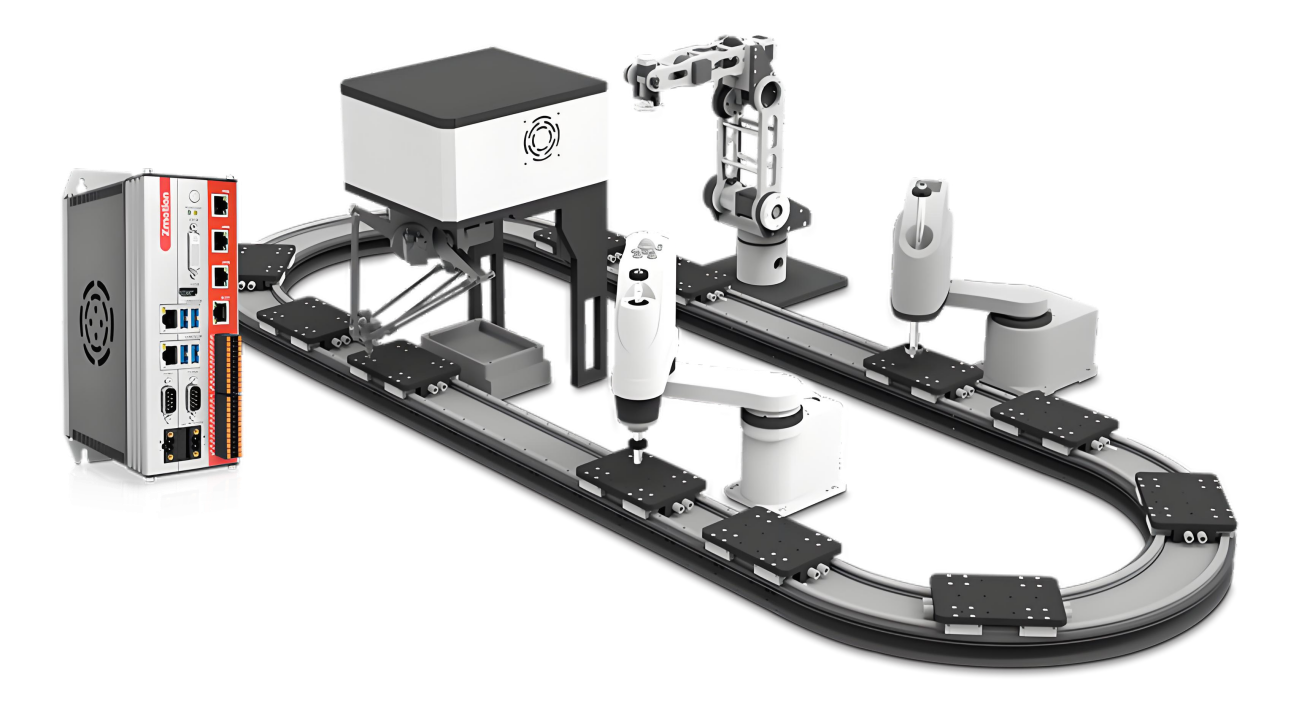

III. OnWei Chuang Automation

Wei Chuang isconveying lineExperts in customised equipment solutions, one-stop shop for the whole process.

The completion of a bespoke solution consists of three aspects: pre-sales, sales and post-sales.

- Before sale, we will firstly design the scheme according to your needs and quote in time, after finalising the customised scheme, we will arrange the production plan.

- There are strict standards from material selection, processing to assembly. Various configurations are also selected from domestic and international reputable brands with guaranteed quality. When the commissioning of our equipment is completed, we will uniformly arrange for delivery to the door. At the same time, we will also arrange technicians to provide technical support according to the actual situation.

- After sales, as we have nationwideafter-sales service pointTherefore, Wei Chuang is specially equipped with corresponding after-sales service, only you have the need, we are always on the doorstep. Completely solve the problem of untimely maintenance and procrastination. From pre-sale to sale to after-sale, all-round gatekeeper for you.