What are you afraid of when choosing conveyor equipment? I'm afraid of choosing the wrong buy back not good. Conveyor line to choose the right, first of all, their classification to have a certain understanding of the following introduction of Wei Chuang's five types of conveyor line, see if there is what you need:

1,Speed Chain Conveyor Line::

Divided into a variety of models, characterised by a strong load-bearing capacity, load 2000kg easily. Chain tensioning device is also installed to adjust the chain tension at any time to make the line run more stable, which can well solve the problem of chain durability that customers worry about. It is very suitable for new energy batteries, auto parts and other industries with heavy-duty conveying needs.

Our belt lines are divided into two main types: one is synchronous belt line and the other is flat belt line. The core advantage of these two types of lines is that they can provide a smooth, dry, clean and low-noise conveying environment than ordinary belt lines, and they can achieve high-precision positioning and conveying. And the cleanliness is also high, able to meet the requirements of the dust-free class of more than 10,000 levels.

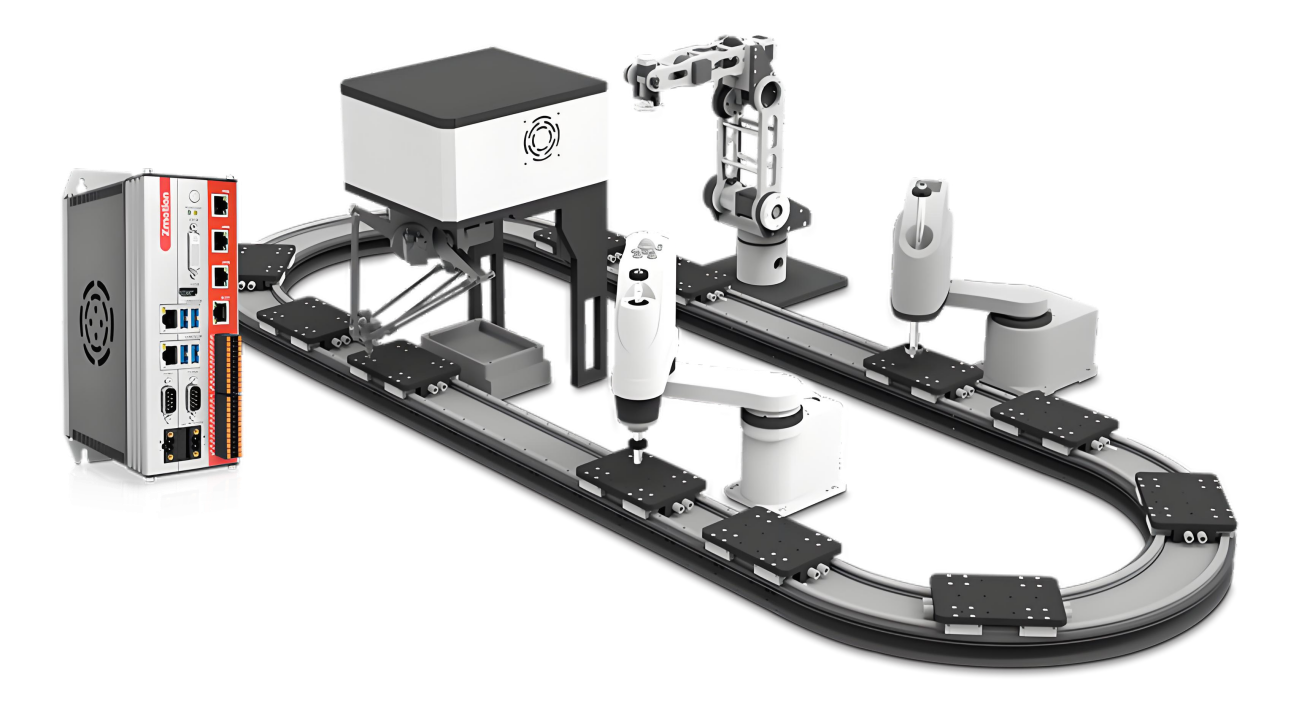

2,Synchronous belt conveyor line::

Synchronous belt can also be called toothed belt, composite material, the longest single section of our conveyor line can be done 6 metres, the maximum load of a single section can be done 60KG, support for forward and reverse operation. Abrasion resistance and stability to withstand the long-term test, and its beat speed can be flexibly adjusted to easily adapt to different working conditions. Whether it is mobile phone and computer assembly, lithium module processing, or auto parts production, a line can handle.

3,Flat Belt Conveyor Line::

flat beltIt can also be called sheet base belt, mainly made of nylon material, with high abrasion resistance, able to withstand greater friction and wear, very suitable for long-term contact with the pallet use. The longest single section can be 25 metres, the maximum load of a single section can be 250KG, unlike ordinary belts, it also has anti-static function and strong tensile resistance, can be in the case of high-speed stable transport. It can be used for automated transport and sorting line, and can be seen in automotive electronics, logistics, warehousing, manufacturing and other fields.

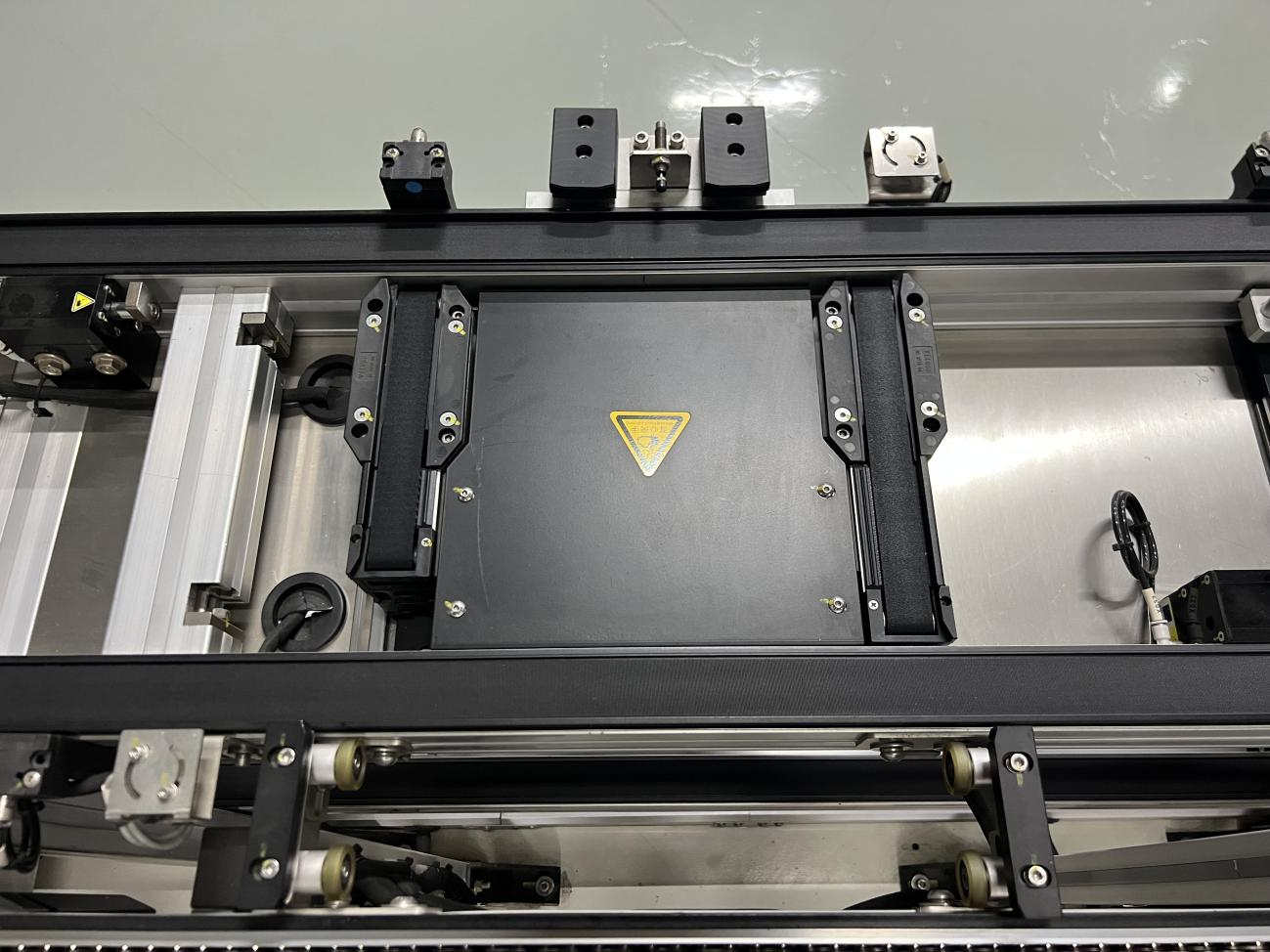

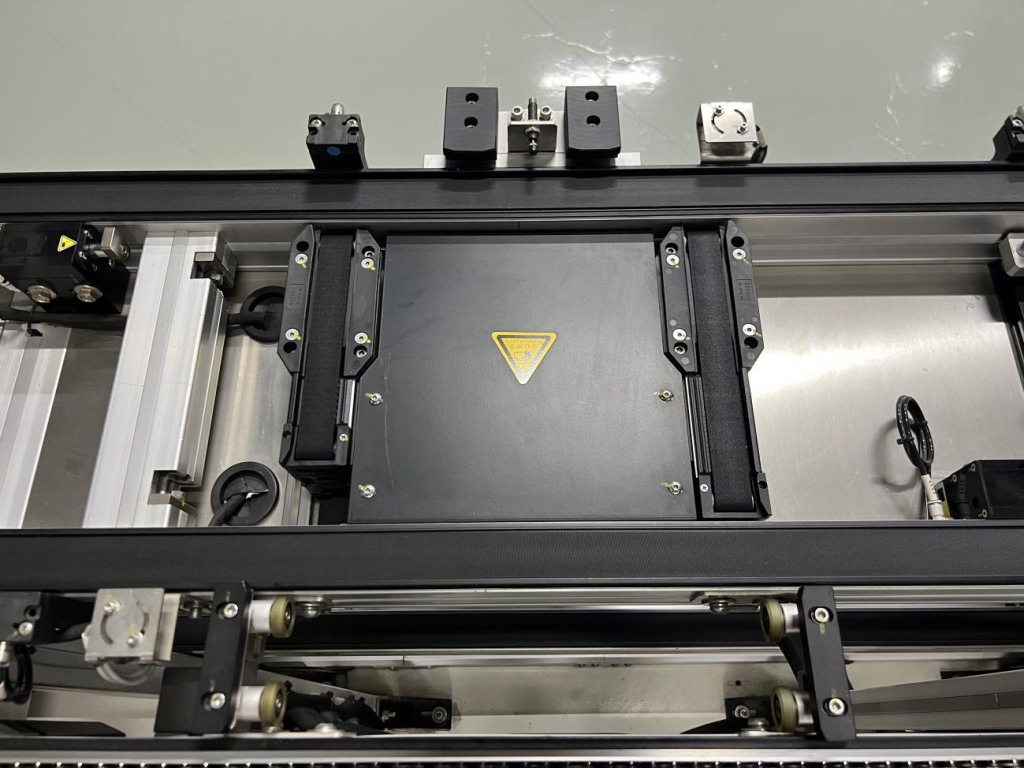

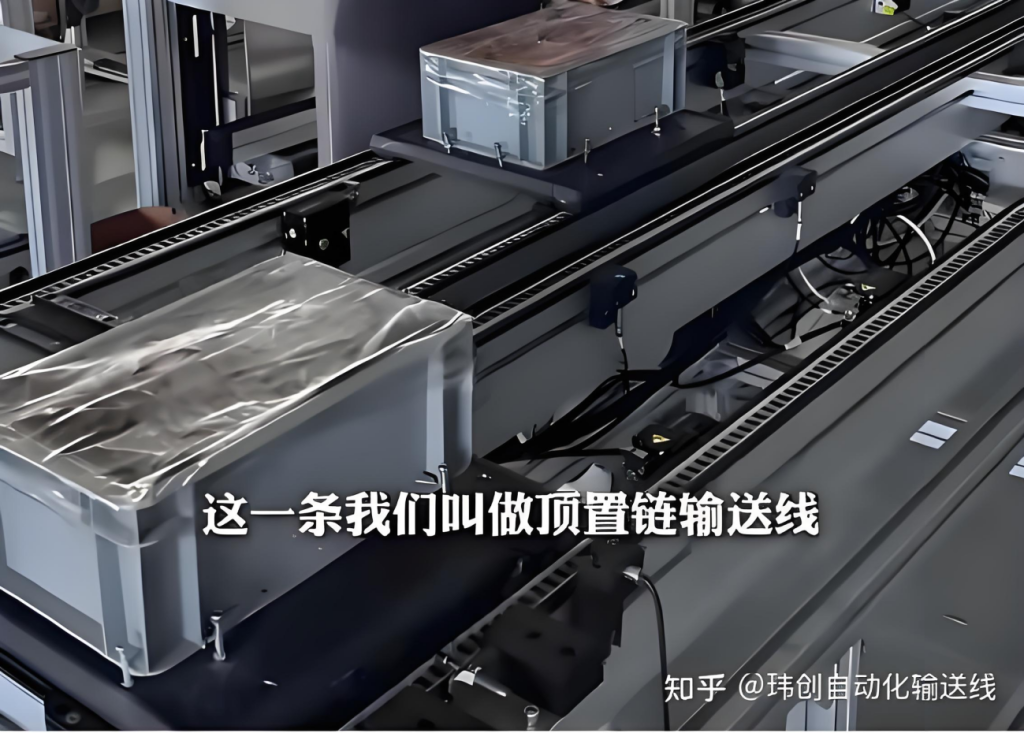

4,Overhead Chain Conveyor Line::

The maximum load of a single section is 200kg and the conveying distance is within 8 metres.Overhead Chain Conveyor LineCompared with other lines, its highlight is that it produces almost no dust during operation, which is very suitable for production lines with high requirements for cleanliness, such as new energy lithium battery assembly lines. There is no need to worry about dust contaminating the battery and affecting production. And the chain is designed with overhead rollers, which runs with less vibration and noise, and is also more wear-resistant than ordinary ones, so the service life of the conveyor line is also very long.

(Image source:Wei Chuang Automation)

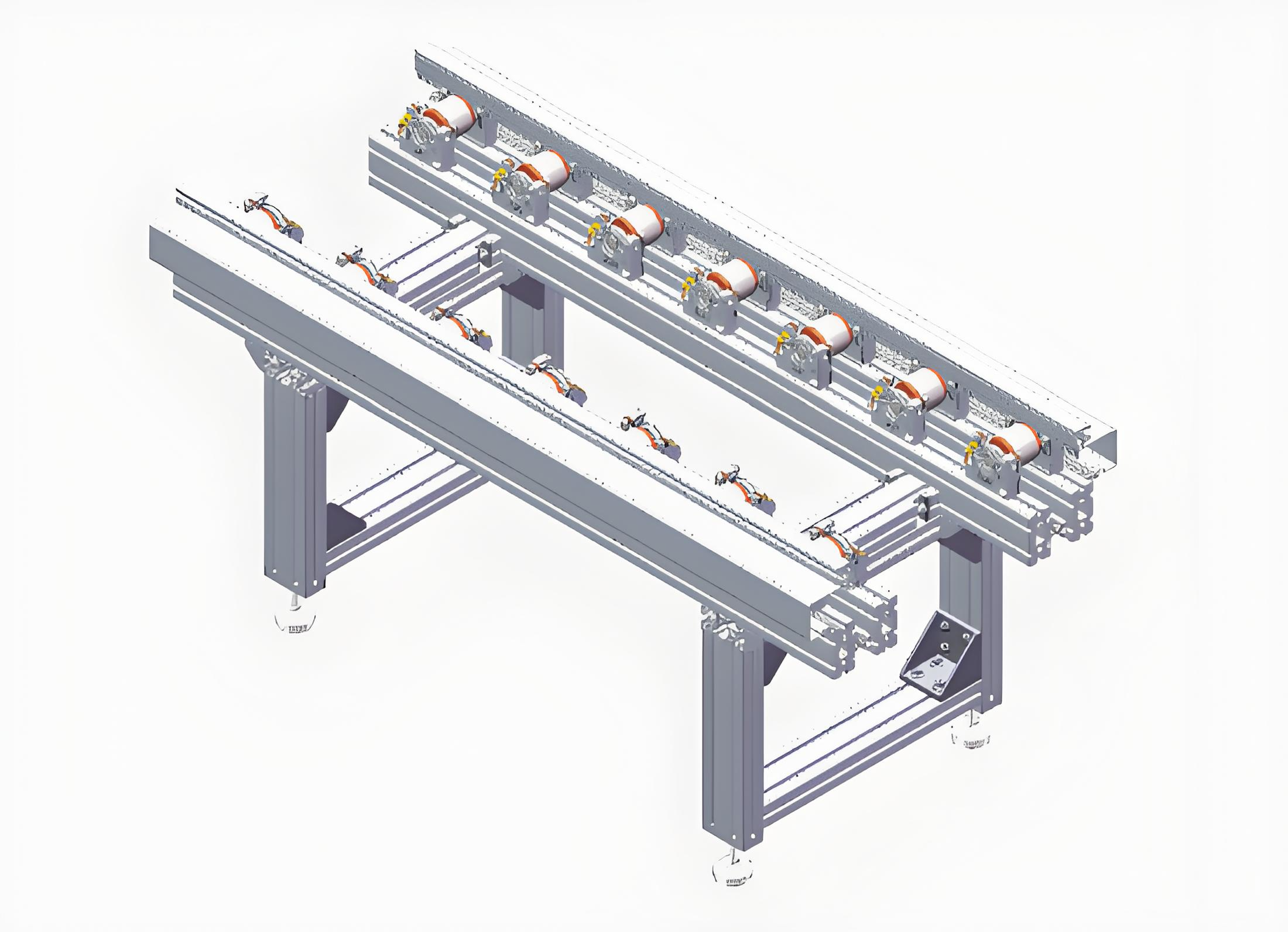

5,propulsionroller conveyorthreads::

A type of light-duty conveyingplatenIt can load up to 300kg in a single section. It can be used in both industrial production and warehousing logistics. The advantage is high efficiency, small footprint, especially suitable for modern factory layout needs. And its working principle is also very simple: it is the driving device drives the drum to rotate, and the material can automatically advance along the drum. So no matter it is bulk, bagged or boxed materials, it can easily meet the transport. If you need sorting or assembly, you can also add different accessories to achieve more functions.