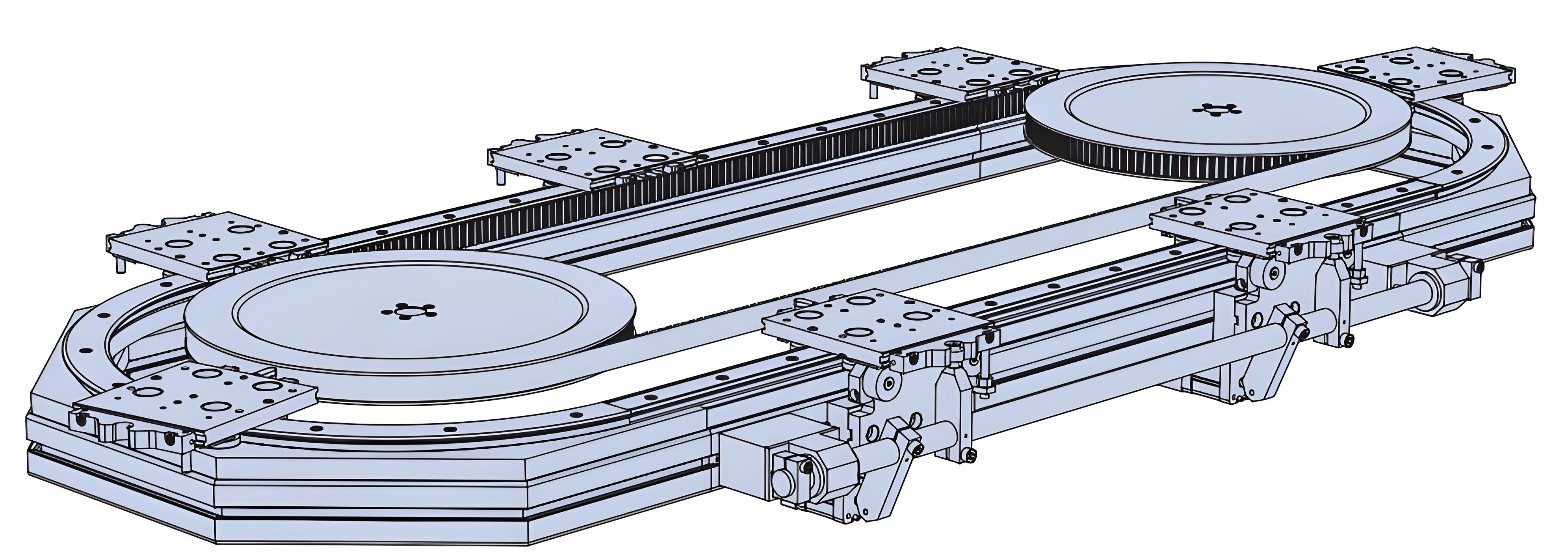

In the automated production of automotive parts, it is critical to get the part from point A to point B accurately and quickly. AndRing guideAs a conveyor system that is not afraid of high temperature and dust, accurate positioning and fast beat, many manufacturers prefer to use it. Here are three common production scenarios for automotive parts, sayCircular guideway conveyor systemsThe specific usage of the

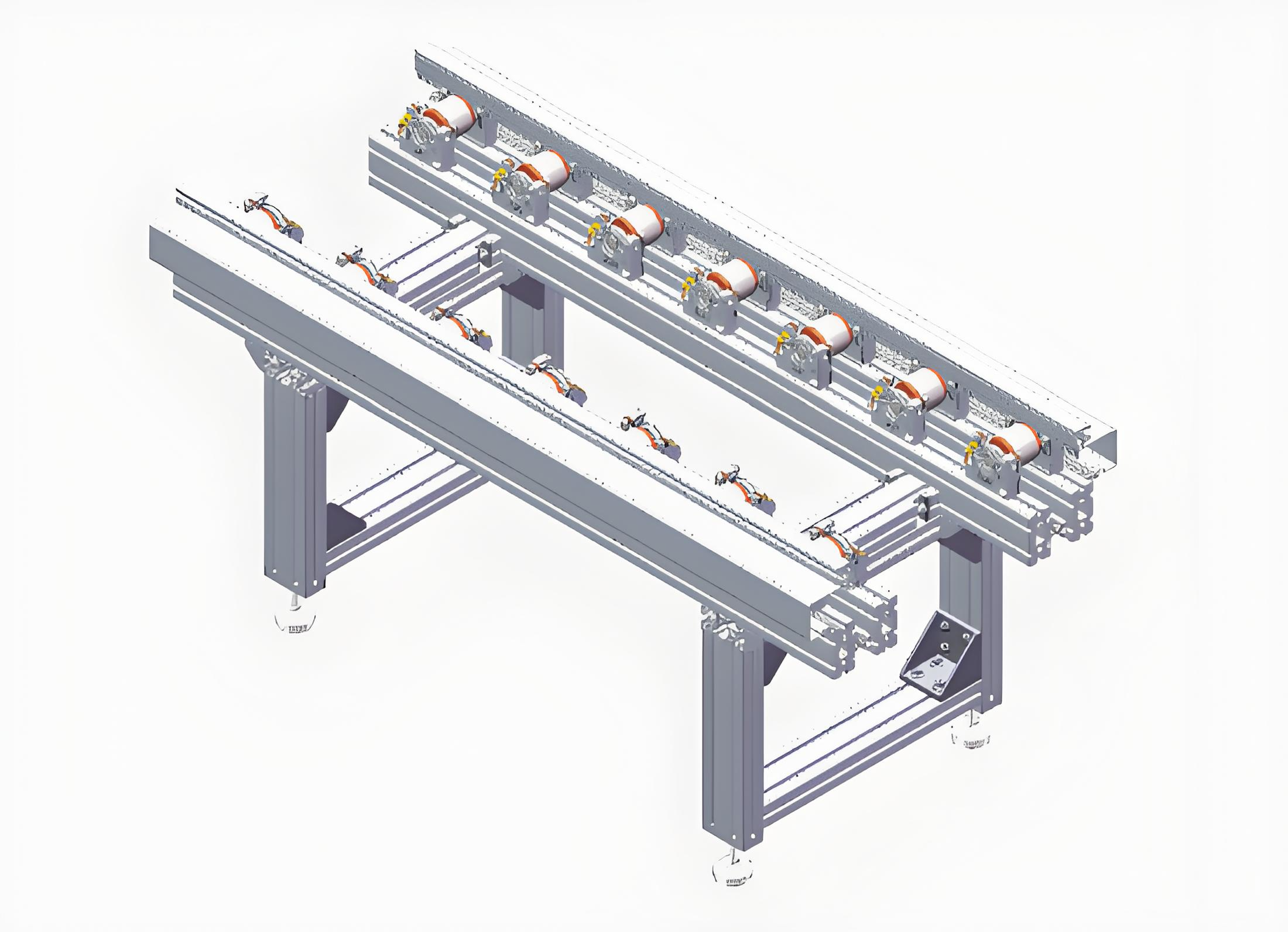

One,Cutting and welding lines for large and small parts

When automotive parts are cut and welded, the workshop temperature is high, and also prone to dust and debris, which requires a high degree of conveying accuracy and speed.Ring guideConveyor systems are just the thing for these needs.

- Adaptive Design:V-rail structure can be used to block dust and debris to avoid these things affecting the conveyance. Installation generally choose horizontal installation, the shape of the line body according to the layout of the workshop choose oval, rectangular or round. Transmission with chain, this transmission mode single slider can load ≤ 50kg, in line with the cutting and welding line load-bearing requirements. After adding the positioning mechanism, the repetitive positioning can be accurate to ±0.05mm, and the conveying precision is completely sufficient.

- Practical applications:Automated production lines for parts like spark plugs, shock absorbers and valve stems use this system to allow parts to move accurately during cutting and welding, increasing production efficiency.

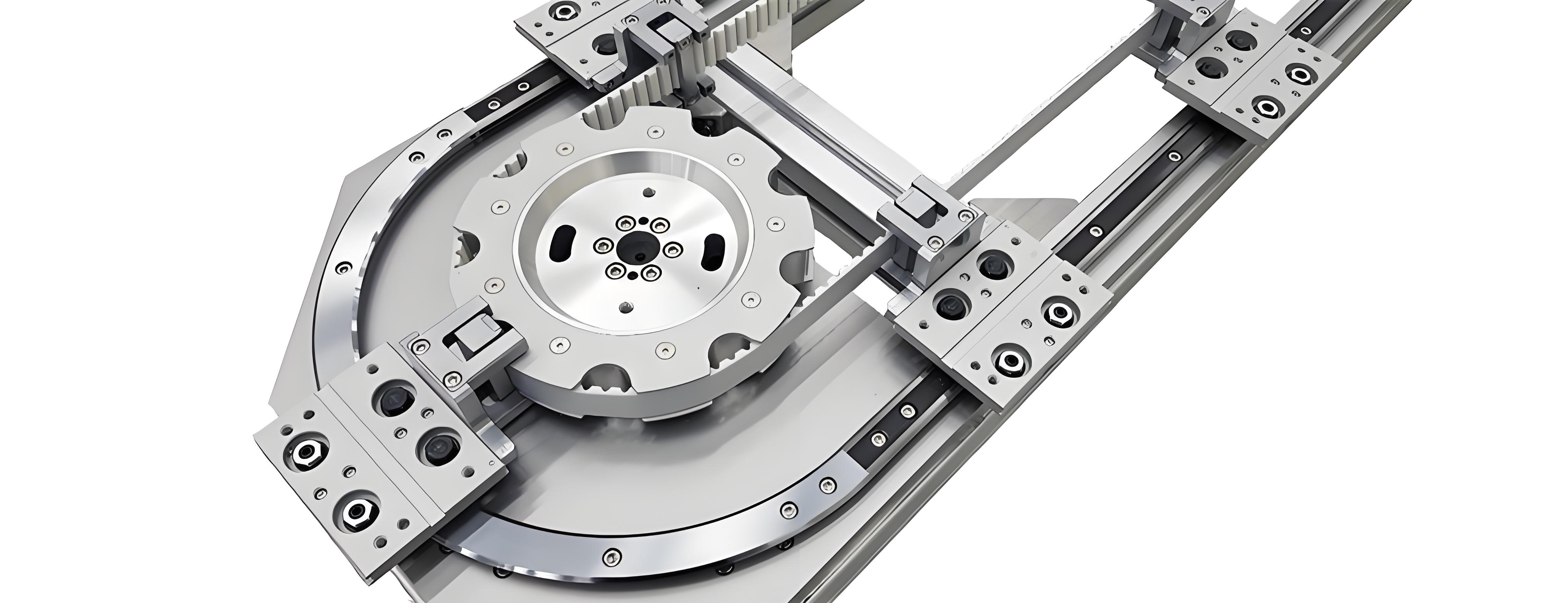

Two,Coating line for exterior parts

The frame, bonnet, doors and other exterior parts of a car are large and heavy, and need to be sprayed over long distances, load-bearing and accurately positioned.Ring guideConveyor systems cope with these demands with ease.

- Core strengths:Adopting chain drive, it can not only realise long-distance conveying (the longest line can be up to 80m), but also withstand high loads, and at the same time, ensure accurate positioning and even spraying of appearance parts when spraying. Moreover, it supports the lifting installation method and does not take up the floor space in the workshop, which is suitable for conveying large-volume appearance parts.

- Applicable Scenarios:In the automated coating line for the parts of the frame, bonnet, doors, front and rear surrounds and boot lid, theCircular guideway conveyor systemsIt can move with these parts on a set trajectory and work with the coating equipment to finish the coating job.

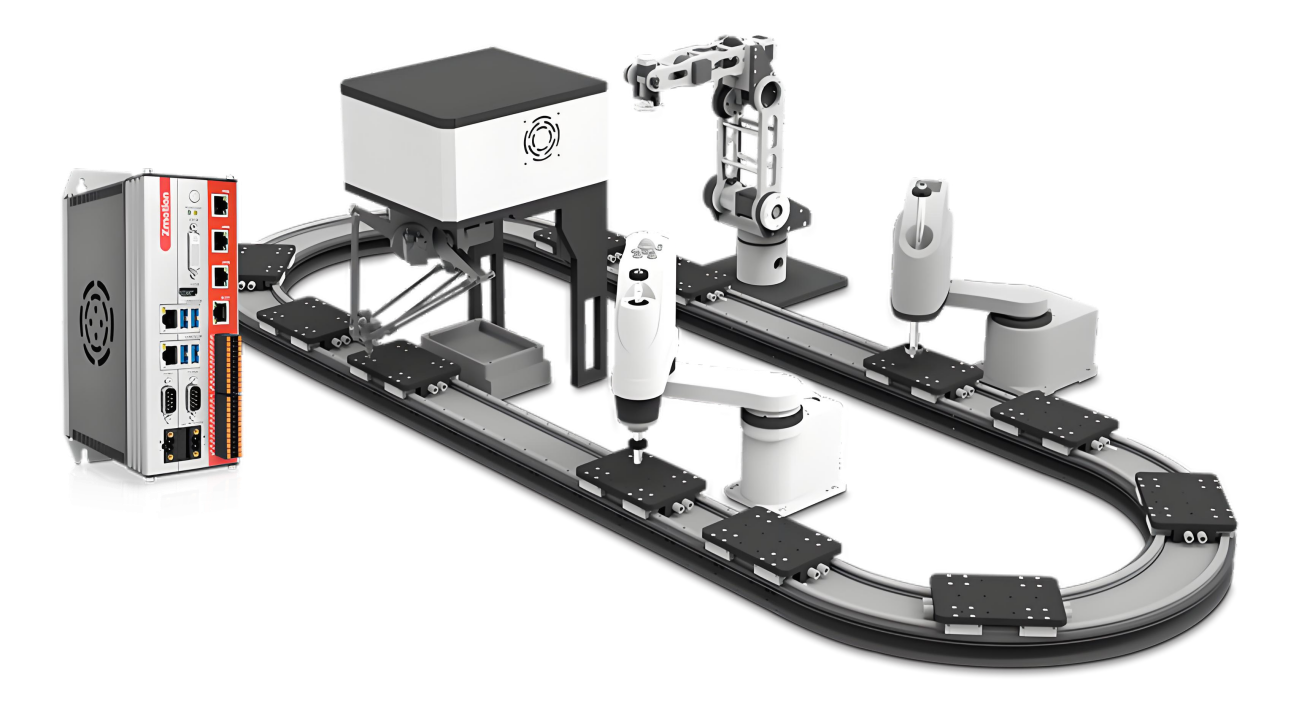

Three,Assembly lines for the production of various components

There are many types of automotive parts, and different parts have different requirements for the conveyor system when they are produced and assembled.Circular guideway conveyor systemsCan be flexibly adjusted to meet a variety of needs.

- Flexible configuration:Installation can be chosen either horizontally or vertically, how to facilitate the layout of the workshop. Conveyor can use single track or double track. In terms of load bearing, choose synchronous belt drive (≤15kg) or connecting rod drive (≤10kg) if the parts are light, choose heavy parts.chain drive(≤50kg)

- Application effects:Whether it is a heavily loaded engine component or a small lightweight electronic component, the ring guide system can be adjusted for precise automated transport. It helps various component manufacturers to improve production accuracy and quality and meet the high demands of automotive production on parts.