Under the wave of Industry 4.0, logistics automation has become the key to upgrade the manufacturing industry. As one of the core equipments of automated logistics system, overhead chain conveyor line has become the choice of many enterprises to optimise the production process with its high efficiency, stability and flexibility. Today, we will start from the various aspects of overhead chain conveyor line, so that you can have a deeper understanding of it:

01 Principle of operation

Overhead Chain Conveyor LineThe working principle is not complicated, but contains subtle mechanical intelligence.

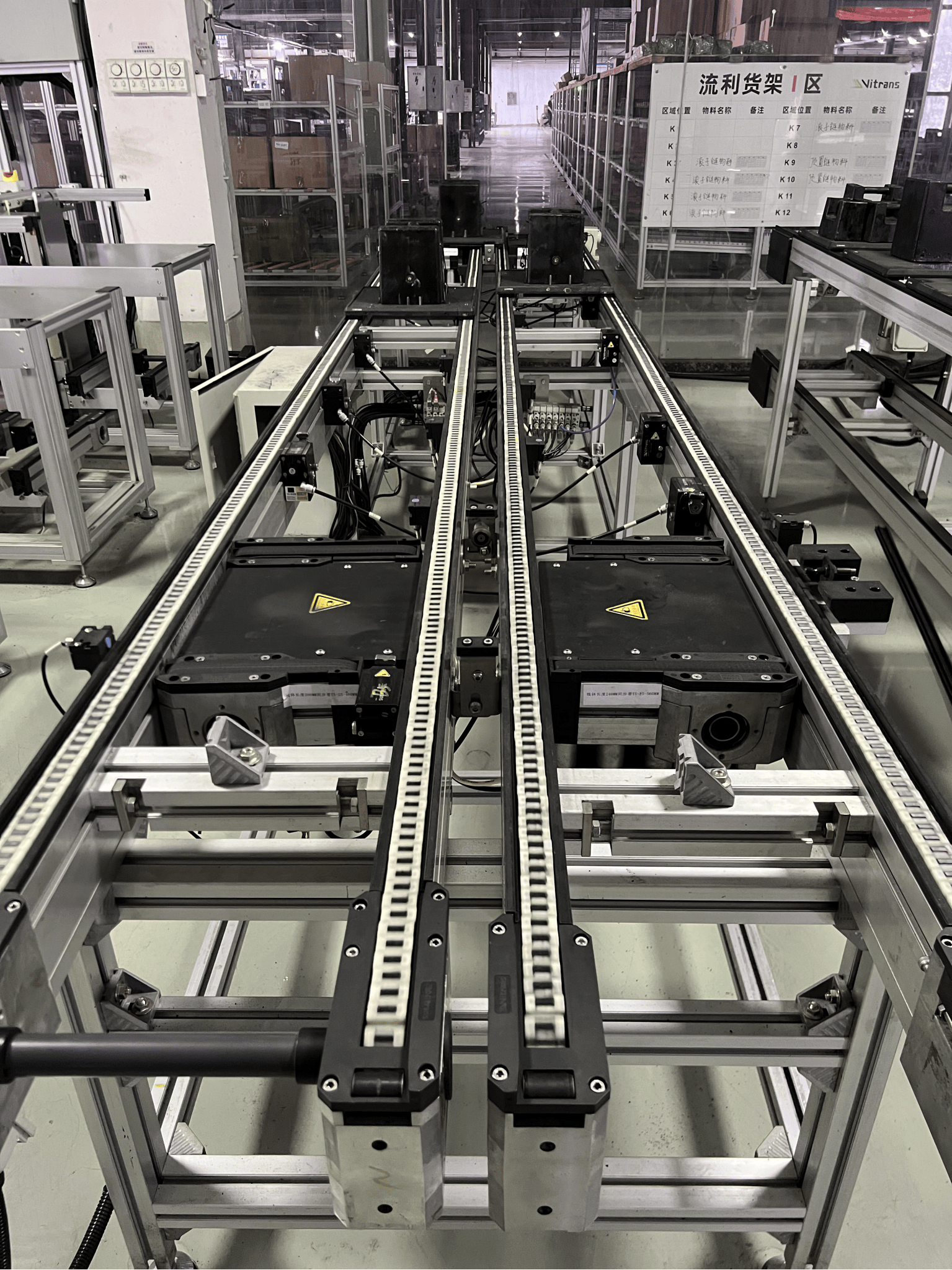

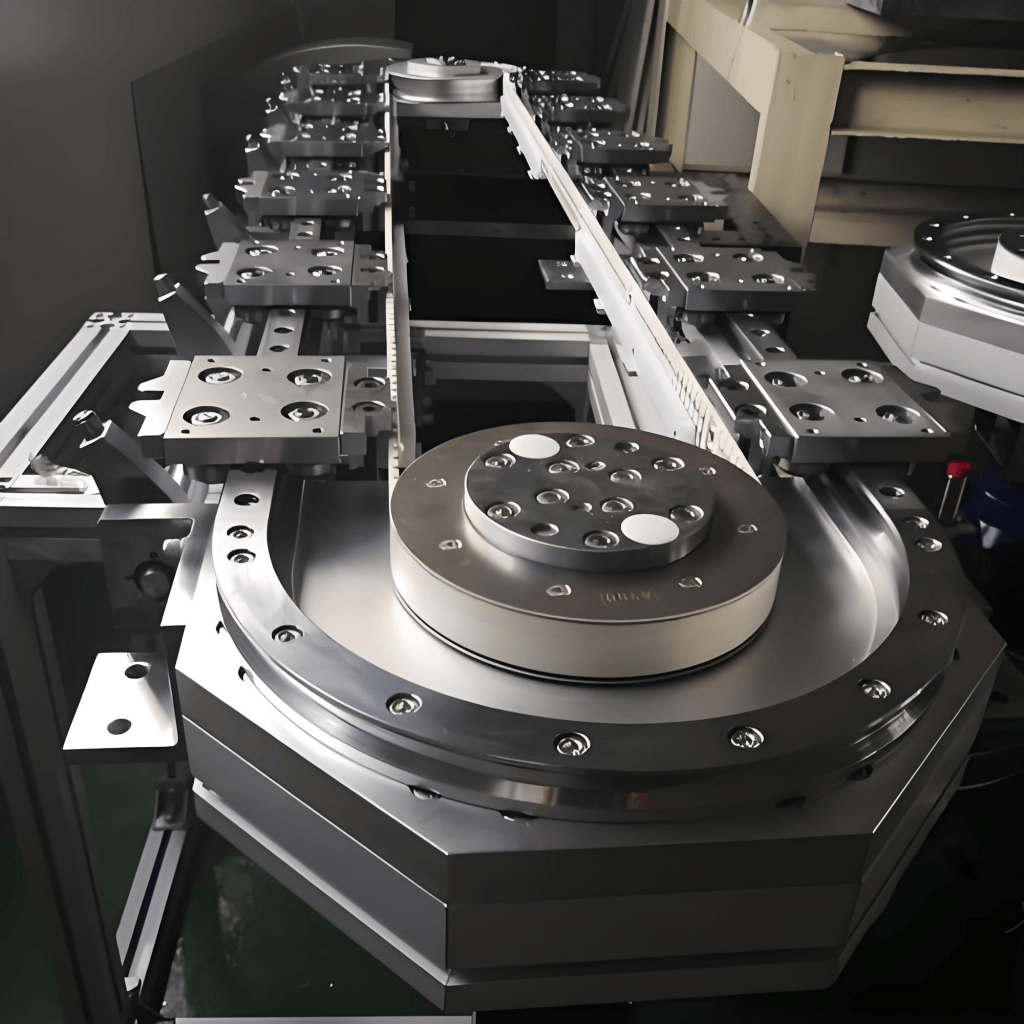

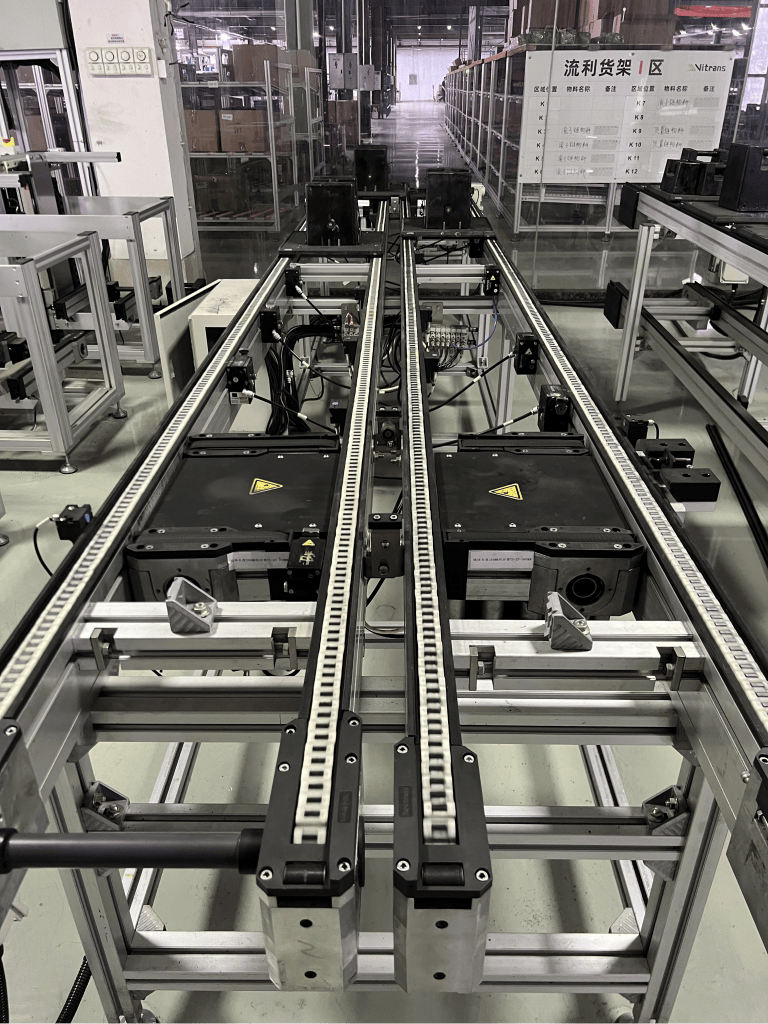

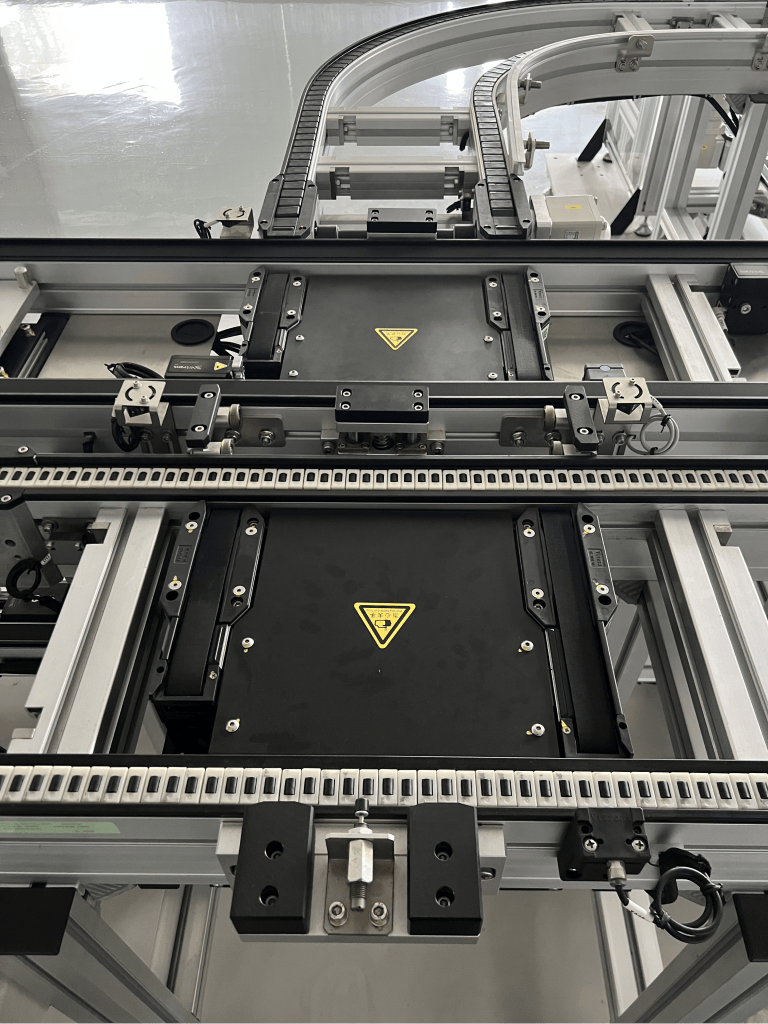

It mainly relies on the power device to drive the chain to circulate the movement, and the chain holds the bearing surface to drive the material to move along the preset path. Whether it is horizontal conveying, or climbing or turning, the overhead chain conveying line can keep the material conveying stably, showing strong adaptability and flexibility.

02 Practical Functions

Overhead Chain Conveyor LineIn practical application, it shows many practical functions:

- Strong load capacity: able to withstand high loads to meet the needs of heavy conveyance

- Stable conveying speed: Ensure that the material is conveyed at a constant speed, avoiding production delays caused by speed fluctuations.

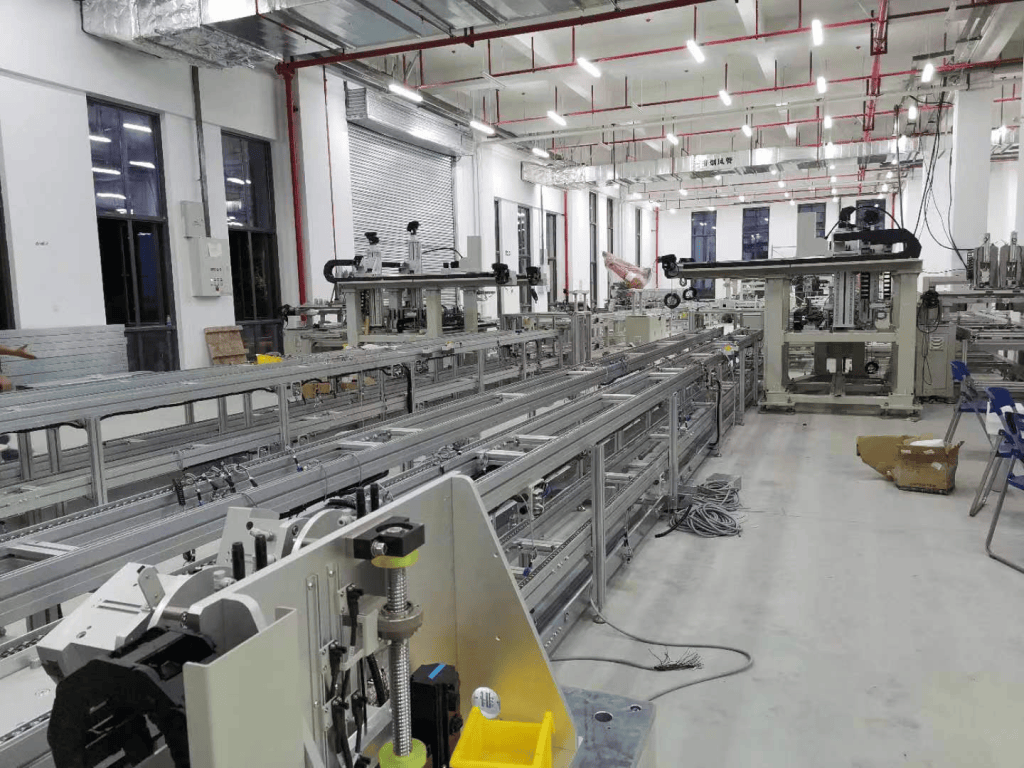

- Flexible layout design: diversified conveying paths can be designed according to the production site and process requirements to achieve efficient use of space.

- Long-term cleanliness level: In dust-free clean rooms and other places with very high environmental requirements, overhead chain conveyor lines can effectively reduce the generation of dust and maintain the cleanliness of the production environment.

03 Products

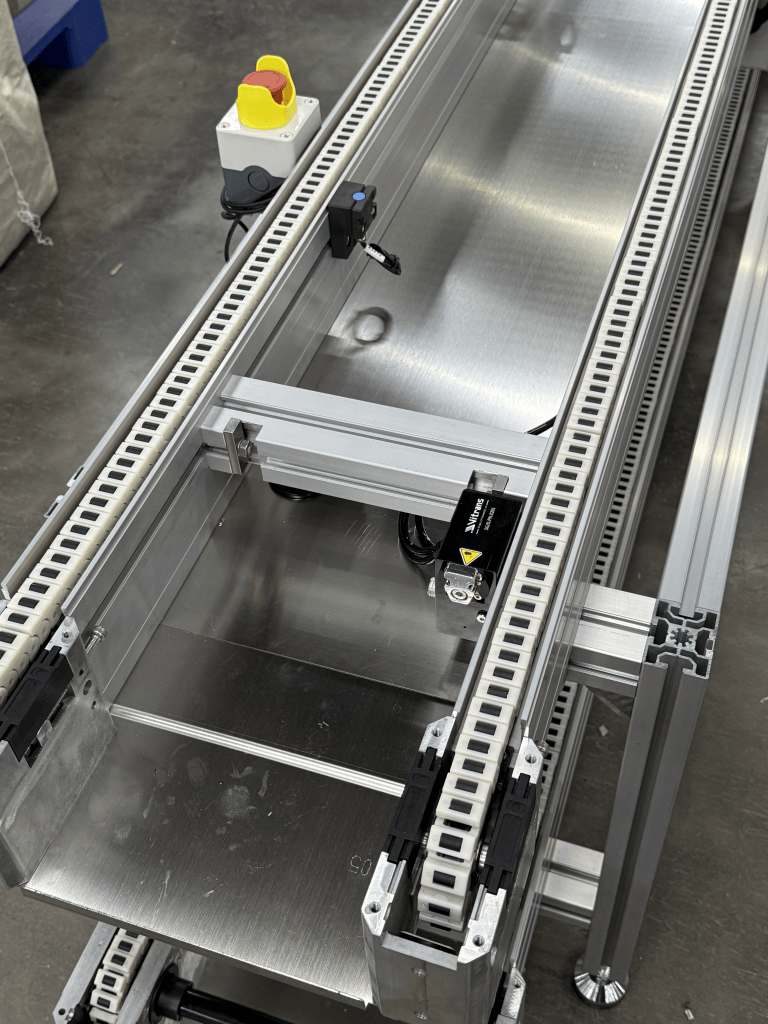

in Wei Chuang'sOverhead Chain Conveyor LineFor example, the product adopts plastic overhead chain as the default conveying medium, with a load limit of 0.5kg/cm per unit length, and its maximum load and unit length can be customised according to the specific requirements to adapt to the conveying of materials of different weights. Meanwhile, the overhead chain conveying line supports modular design, which can be easily expanded and maintained to meet the diversified needs of enterprise production lines.

04 Wide range of application scenarios

The application scene of overhead chain conveyor line is very wide. In the field of automobile manufacturing, it is mainly used for assembling and transporting automobile parts; in the food and beverage industry, it is suitable for labelling, filling, cleaning, etc.; in the logistics and warehousing industry, it helps the goods to be sorted and handled efficiently; in the dust-free and clean workshop, theOverhead Chain Conveyor LineWhat's more, with its advantage of high cleanliness, it has become the ideal choice for chip manufacturing, precision electronic component production and other industries.

05 Maintenance tips

In order to ensure the long-term stable operation of the overhead chain conveyor line, the following maintenance tips should not be ignored:

1. Regularly check the wear and tear of the chain and add lubricant in time to prolong its service life.

2. Check and maintain the key components such as driving device and tensioning device to ensure the stable operation of the whole conveying line.

3. Regularly clean the surface of the conveyor line and the surrounding dust, debris, to prevent the entry of foreign objects to affect the operation of the

4. Regular and comprehensive equipment overhaul and maintenance based on frequency of equipment use and manufacturer's recommendations

Overhead chain conveyor is not only a key equipment for logistics automation, but also an important step towards intelligent production. Through the introduction of overhead chain conveyor lines, enterprises can significantly improve production efficiency, reduce operating costs, and take advantage of the fierce competition in the market.

Wei Chuang Automation

Wei creation as a manufacturer with more than 10 years of R & D and manufacturing of conveyor equipment, long-term commitment to the production and processing of automated conveyor line equipment, sales, to provide users with high-quality, professional conveyor system and more efficient, intelligent, reliable transport solutions, so that customers experience a professional, caring selection and procurement process.

Products include all types of conveyors, including pallets, doubler chain lines, flat belt lines, timing belt lines, roller lines, and ring guides,magnetic levitation line, and a variety of conveyor modules, including jacking traverse, jacking positioning, and round belt turns,flat-top chain curveAndSynchronous belt elevatorThe products are widely used in various fields such as lithium-ion battery, shoes, 3C electronics, lighting and automobile manufacturing.