In modern industrial automated productionFlexible chain conveyorWith its unique advantages, the line has become a powerful assistant for many enterprises to improve production efficiency and optimise process flow. With flexibility and adaptability at its core, it provides efficient conveying solutions for diverse production scenarios. Today, let's explore the wonders of flexible chain conveyor lines.

01conceptual

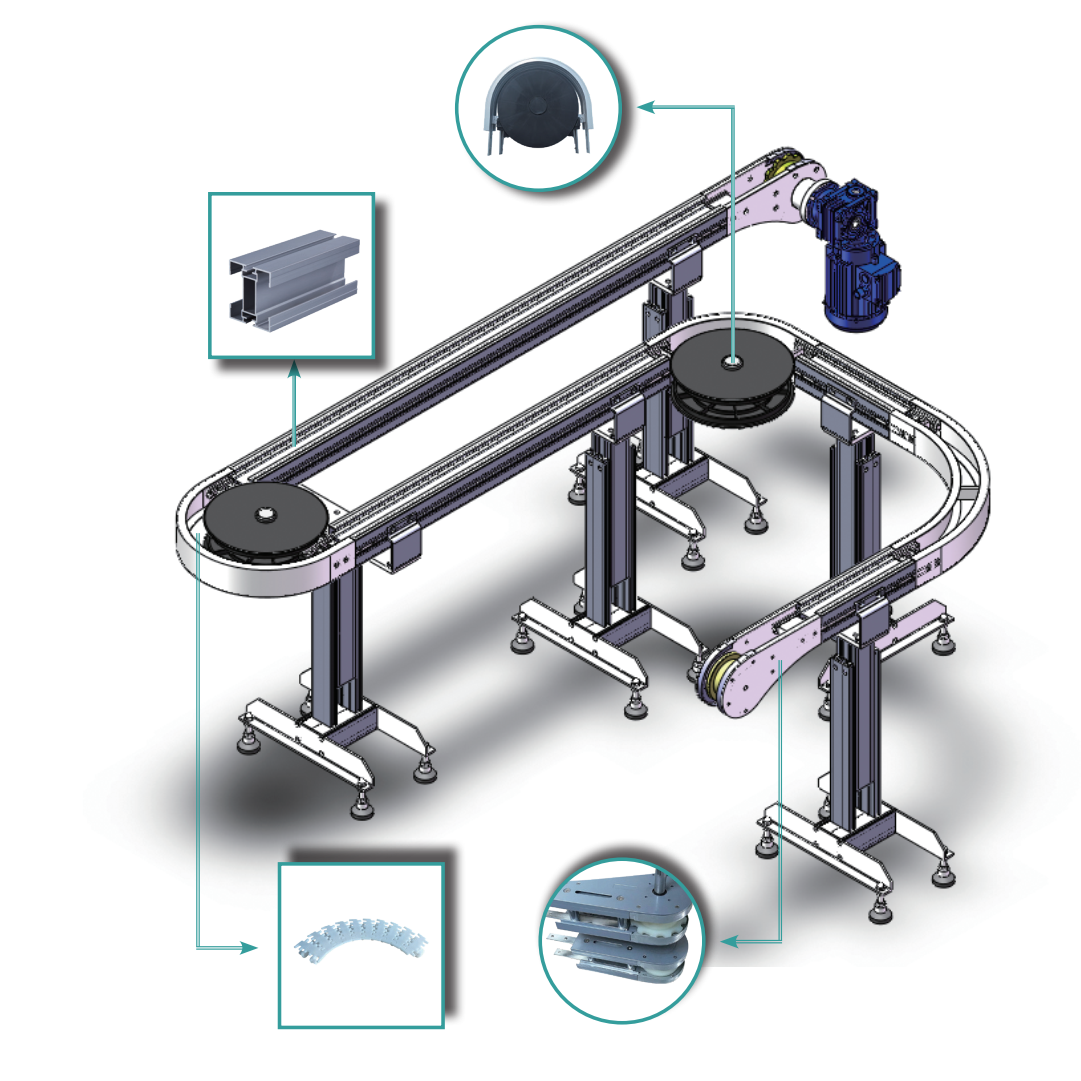

Flexible chain conveyor line, as its name suggests, is a highly flexible and adaptable material handling equipment. It is called "flexible" mainly due to its key component material - aluminium profiles. Aluminium profiles are not only lightweight and easy to cut and transport quickly, but also have excellent bendability, which makes it easy to modify and adjust the length and height of the conveyor line directly according to the actual production layout requirements at the installation site, so as to facilitate the production of the required path of the conveyor line.

02Structure composition

Flexible chain conveyorThe system mainly consists of two main parts, the central control system and the flexible conveyor belt, which work together:

- Central control system:

With PLC, PC or sensors as the core, just like the "intelligent brain", it achieves the automatic management of the whole process of conveying through accurate signal acquisition and logical judgement.

(2)Flexible conveyor belts:

①Conveyor chain: made of high-strength engineering plastics, wear-resistant and corrosion-resistant, long-lasting and stable material carrying.

②Conveyor beam: anodized aluminium alloy or stainless steel, the former is beautiful and durable, the latter meets the needs of food, medicine and other clean scenes.

③Conveyor frame: light, medium and heavy specifications, suitable for different load scenarios, from light materials to heavy equipment can be transported stably.

④Driving device: Aluminium driving head and tail with single/double/intermediate driving mode, the motor provides strong power, adapting to long and short distance, even/varying load demand.

⑤ Guiding device: The guardrails on both sides are like "guardians" to ensure that the materials run precisely along the predetermined path and reduce the risk of deviation.

(6) Turning device: Horizontal/vertical elbows, horizontal wheels and other internal support components help the conveyor chain to turn flexibly and break through the limitation of straight line layout.

03 Flexible chain conveyor line ofspecificities

Flexible chain conveyor lineThe core competence of the company cannot be separated from these six characteristics:

– Smooth and low consumption:Flat and smooth conveying surface reduces friction, smooth material transition and reduces maintenance costs and energy consumption.

– Variety of materials:Stainless steel, engineering plastics and other materials and a wealth of specifications to meet the needs of food, electronics, chemicals and other industries.

– Layout flexibility:Flexible layout with a small turning radius allows horizontal, inclined and turning conveying on a single conveyor line, saving space.

– Quiet and efficient:The noise level is less than 30Db, which enables high-speed and low-noise operation and creates a comfortable production environment.

– Cleaning is convenient:Can be washed or even immersed directly in water to meet the stringent hygiene standards of the food and pharmaceutical industries and ensure product safety.

– Modular design:The shortest possible time to build the functional modules required by the customer's production line, which can be reused to extend the life cycle of the equipment.

04Advantages and areas of application

Flexible Chain Conveyor LineIt has the advantages of dexterous, lightweight, beautiful and standardised structure, and because of the modular design, it is quick to install, easy to operate, has the advantages of small turning radius and strong slope climbing. It can be made into a variety of conveyor, push, hanging, clamping various conveyor, composed of aggregate, diversion, inspection, merging various functions, and according to the different needs of the user, the formation of a variety of forms of production lines.

So it's widely usedHigh hygiene requirements, small site area, cleanliness, high degree of automationThe production line with application scenarios covering industries with high hygiene requirements and limited space, for example:

①Food & Beverage: Hygienic conveying of bottled/canned products;

②Toilet rolls: Stabilise the transmission of paper rolls to avoid contamination;

③Cosmetics/Tobacco: Precision transfer of packaging containers and cigarette packet materials;

④Motor/mechanical parts: Automated conveying of parts to complete processes such as cleaning and machining.

In a word, flexible chain conveyor line plays a vital role in the process of modern industrial automation with its unique advantages and wide applicability. In the future, with the continuous progress of technology and production process optimisation, we have reason to believe that the flexible chain conveyor line will continue to innovate and upgrade, bringing more surprises and changes to the global industrial production, and helping enterprises to move towards a new era of more intelligent and efficient production.