-What is a palletised conveyor system-

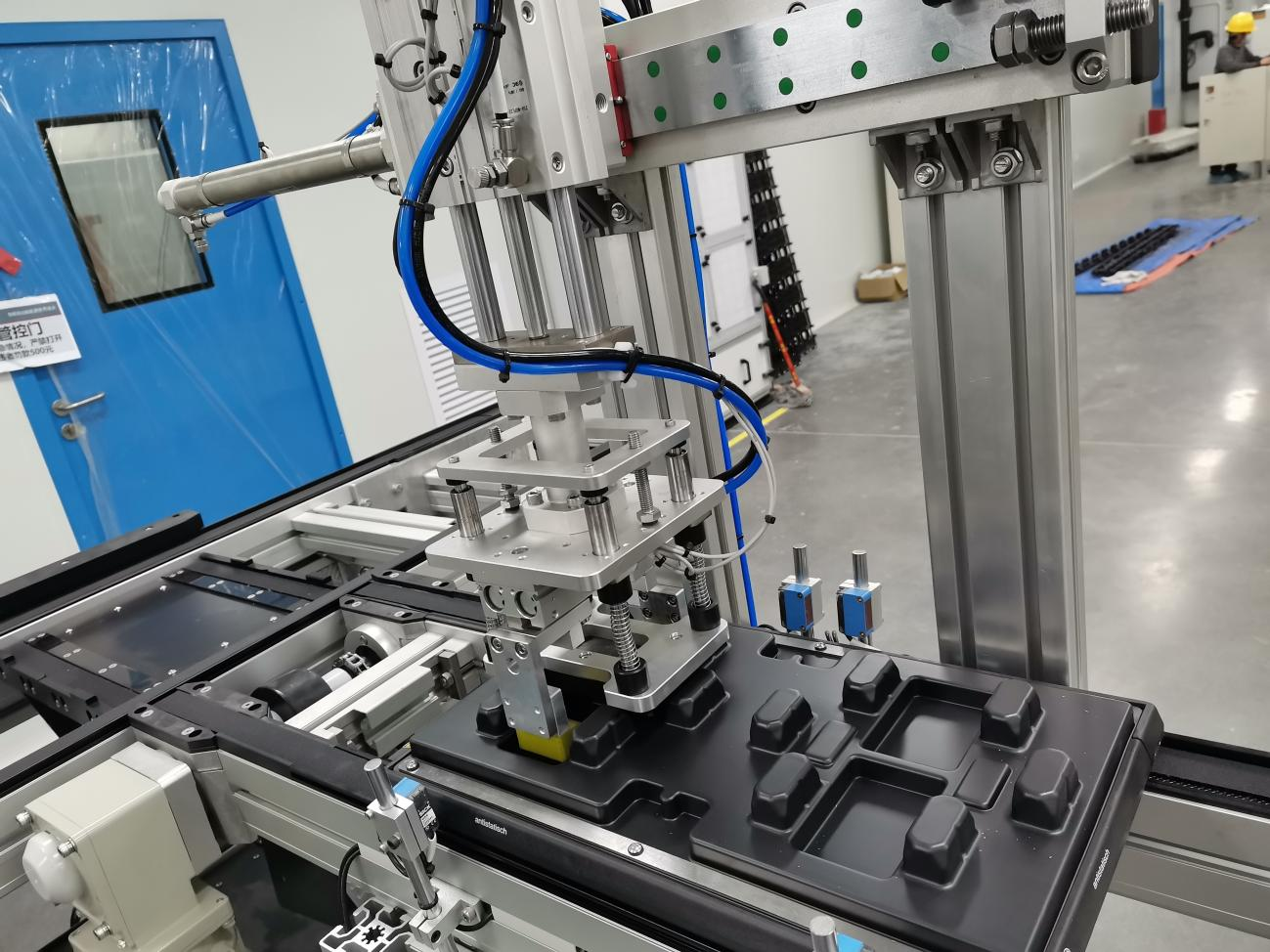

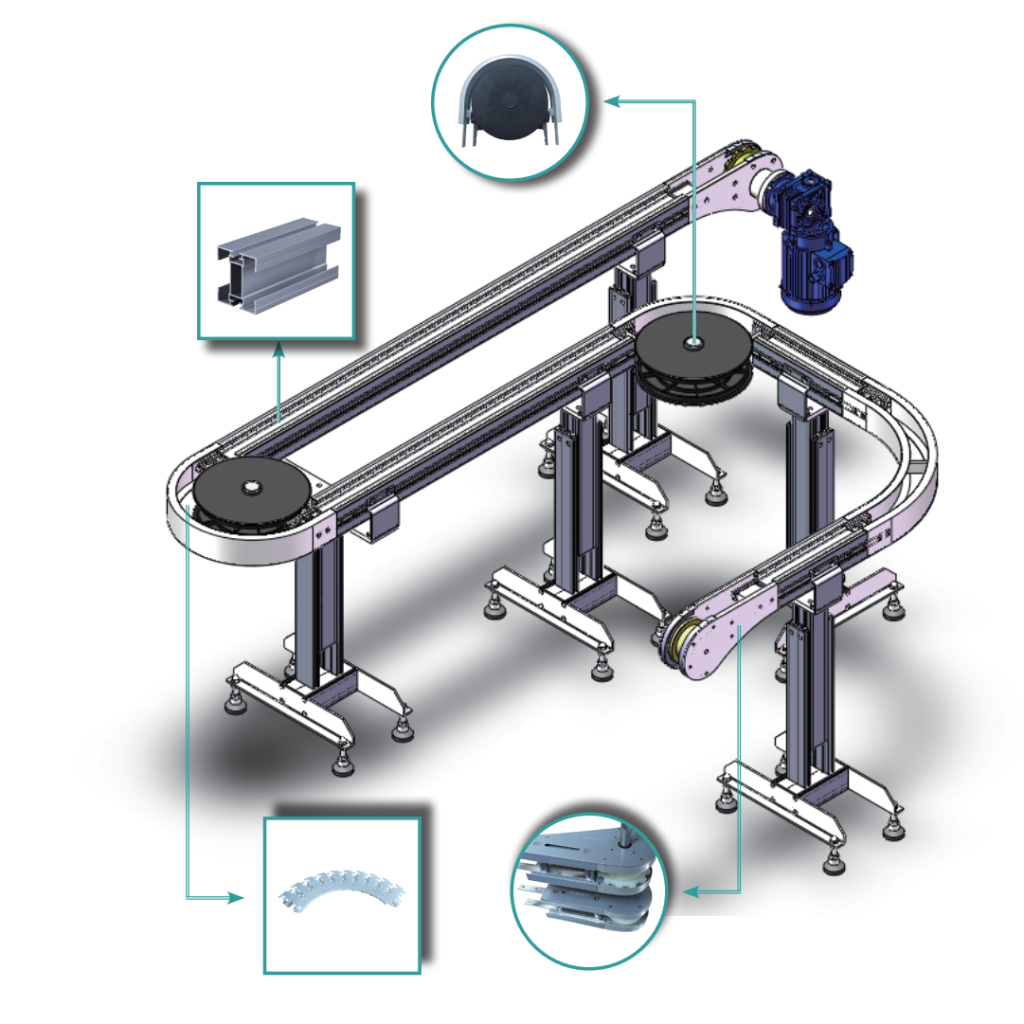

Pallet conveying systemsIt is a system of automated or semi-automated equipment used to carry and convey pallets and the goods on them. These systems are widely used in a variety of production, logistics and warehousing environments, especially in industries such as automotive manufacturing, electronics manufacturing, food processing and others. Pallet conveying systems move pallets from one position to another by means of different types of conveyor modules (e.g. rotary tables, hoists, etc.) to achieve fast, accurate and efficient transport of goods.

-The Role of Pallet Conveyor Systems-

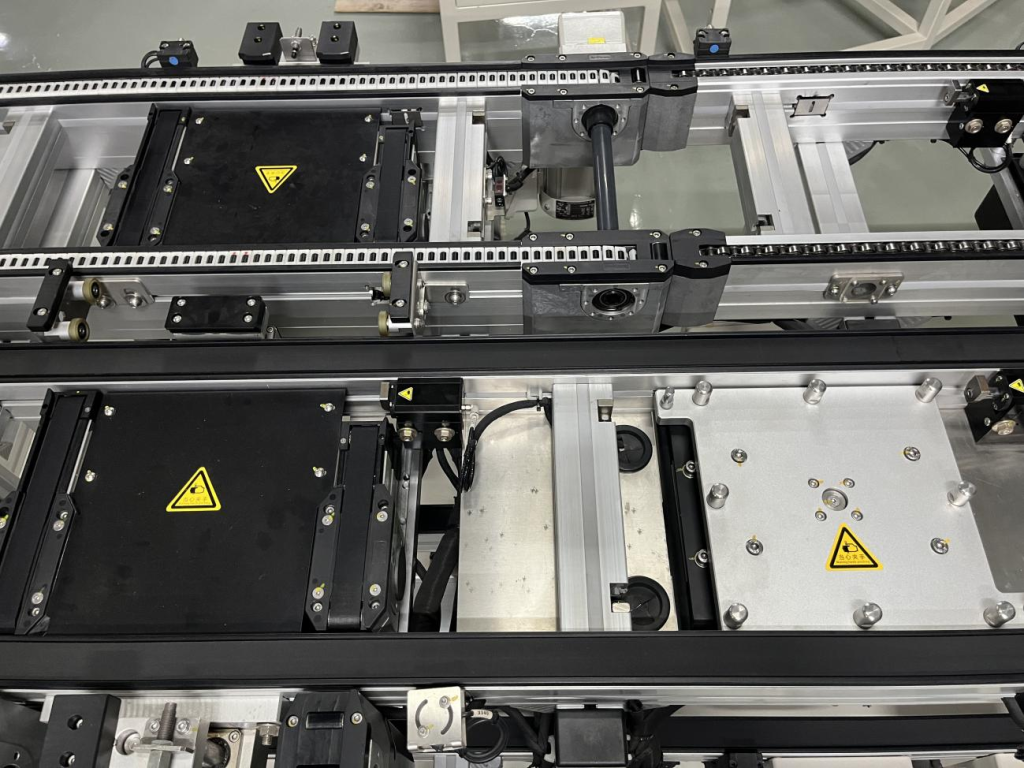

Automated Pallet Conveyor SystemsIt is the central part of an automated warehouse. It is like a "transport link" in the factory, which can connect the various logistics sites closely. From the material transfer between people and workstations, to the flow between workstations and workstations, and then to the processing link and storage area, processing link and assembly link, it can easily handle. Moreover, it is not only the mover of goods, but also plays the role of material staging and buffering to maintain the smoothness of the whole production process.

-Pallet conveying systemsMain characteristics of the -

Efficient:

The ability to transport pallets and goods automatically improves the efficiency of logistics and transport.

Flexibility:

It can be flexibly adjusted according to the logistics needs to meet the transport requirements of different scenarios.

Security:

Equipped with professional safety protection devices to ensure that the goods during transport

The safety of the

Cost-effectiveness:

Reduce labour input and logistics costs, and improve the economic efficiency of enterprises.

-Pallet conveying lineHighlights of the model -

–Continuous conveying with high capacity :It adopts continuous conveying method with high conveying capacity. It can work uninterruptedly and also has a long service life with a high conveying speed.

–Simple structure, stable power :The structure is relatively compact and reasonable, the load is uniform and the speed is stable. In operation, the power consumed is generally small and not very variable, and it is relatively easy to maintain.

–It can be transported over long distances and is easy to control automatically:The length of a single conveyor line can be lengthened, and multiple conveyor lines can be combined to form long-distance conveyor lines. It is particularly easy to achieve programmed control and automated operation, making the whole conveying process more intelligent.

–Convenient material caching:The material caching function can be easily handled on the conveying line. When there is a short period of congestion or different demand in the production chain, it can temporarily store the goods and continue conveying when the time is ripe, effectively regulating the production rhythm.

-Pallet conveying systemsApplications of the -

Manufacturing field (also known as production field) is one of the earliest application scenarios of pallet automation logistics system. It is indispensable in many industries such as machinery, automobile, new energy, electronics, home appliances, shoes and clothes, food, beverage, pharmaceutical, chemical and so on. It mainly solves the problem of transmission of raw materials, purchased parts, intermediate parts and manufactured products, so that these materials flow efficiently and orderly in the factory, and plays an important role in the efficient operation of factory production.