In factories, logistics centres or production lines, roller conveyors, also known asroller conveyor, is one of the most common transport devices.

The principle is to use the synchronous rotation of the roller, the friction of the roller surface to promote the movement of the object. It is able to convey materials with large weight of single piece, or withstand large impact load, with large conveying capacity, fast speed, light and fast operation, and able to realise the characteristics of multi-variety common line shunt conveying.

I. Classification according to driving mode

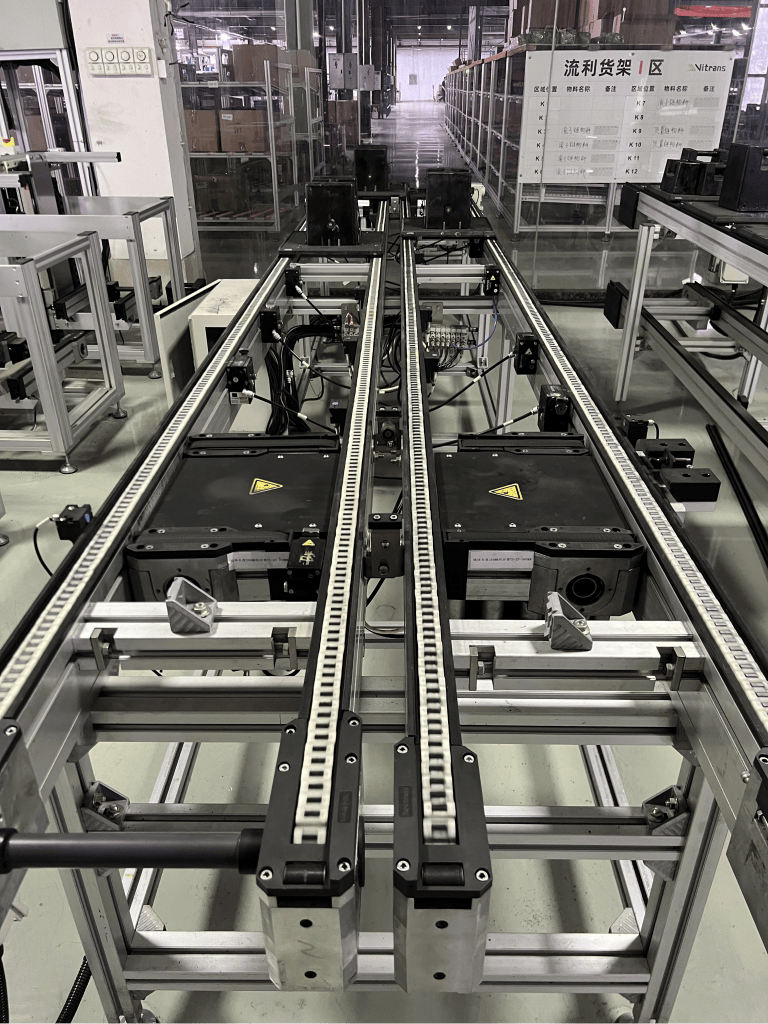

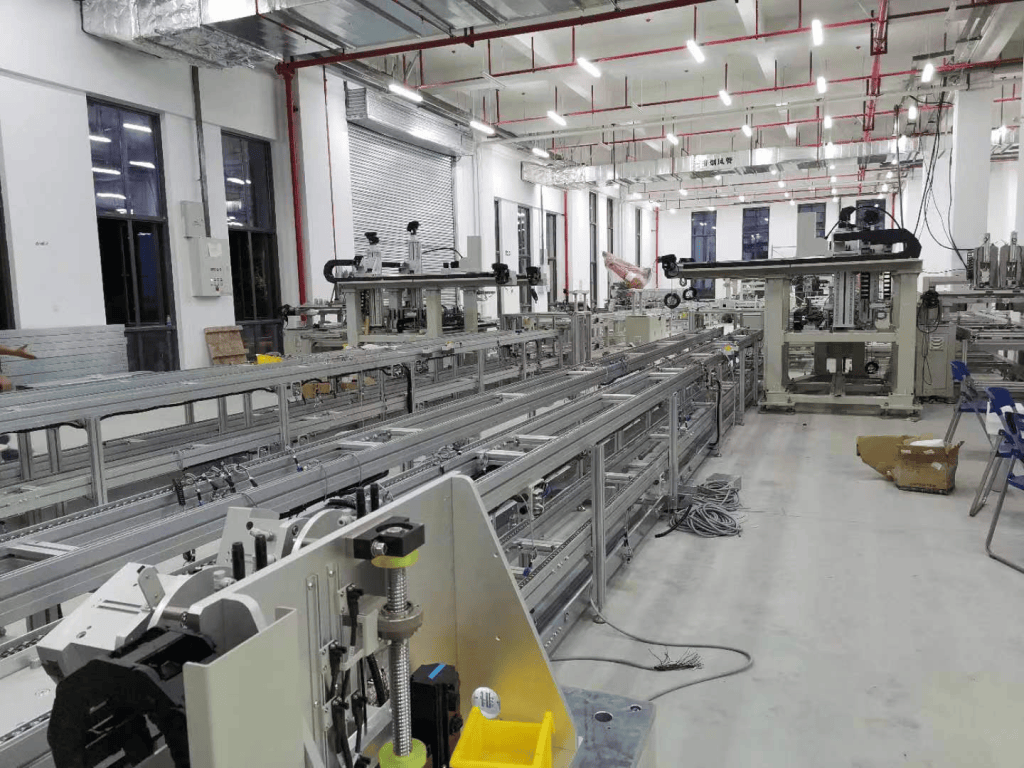

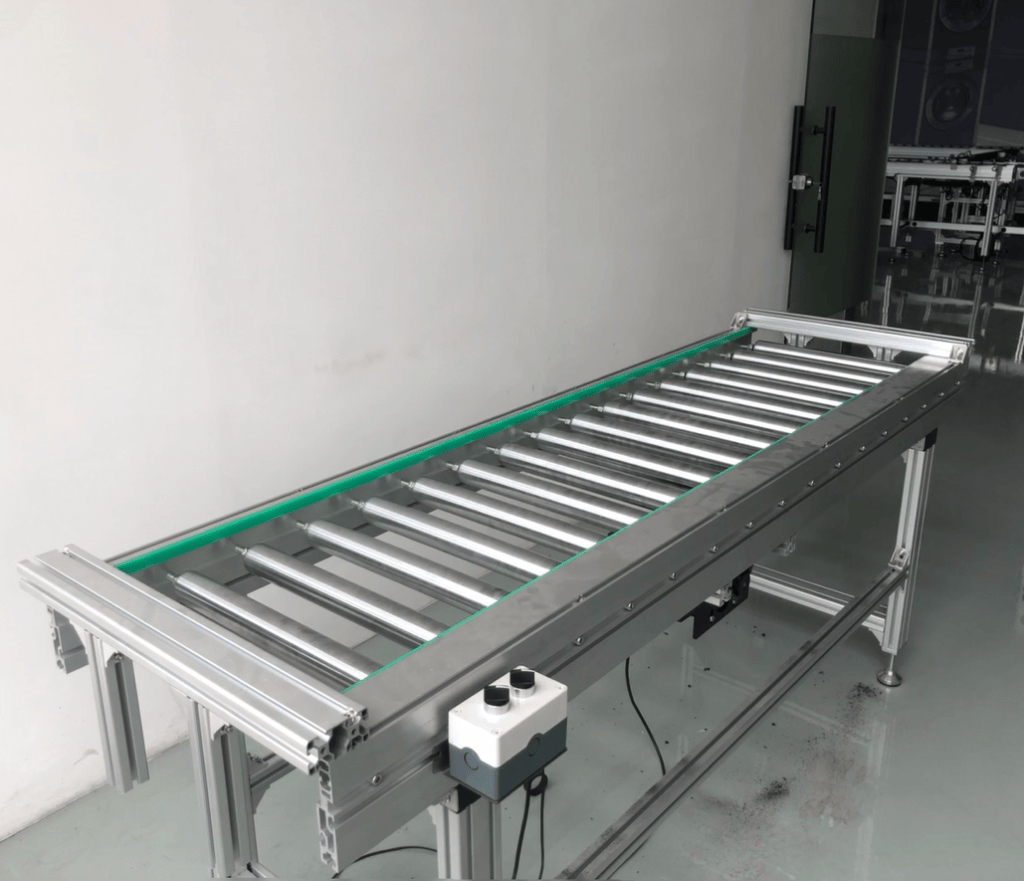

1、Power roller conveyor

propulsionRoller ConveyorIt is an important type of roller conveyor, commonly used in horizontal or upward slightly inclined conveying lines.

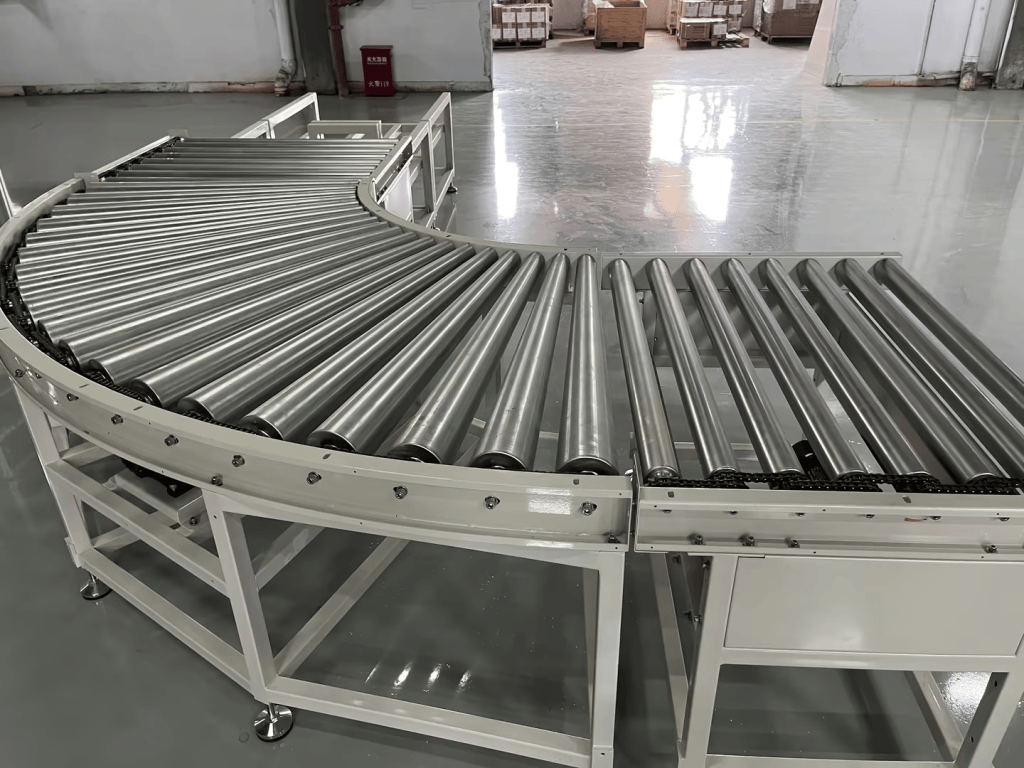

2、No power roller conveyor

Simple design, space-saving, convenient installation, mainly used in the class of boxes, bags, pallets and other pieces of goods conveyor.

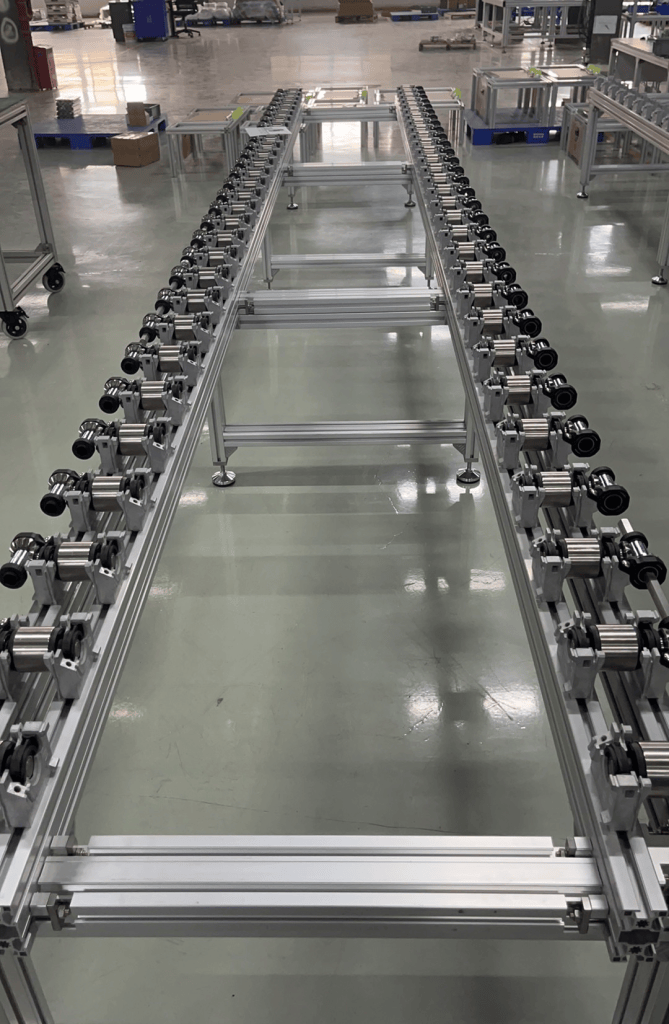

3、Accumulating roller conveyor

With speed regulation and temporary storage function, it can adjust the conveying speed according to the production demand to ensure stable operation, and it can also temporarily store the items to prevent the items from continuing to convey, and play the role of adjusting the spacing or rate of the items.

Two,Core differences

1. Power Roller

-Autonomous drive: no external force is required, speed and direction can be adjusted through the control system to realise automated transport.

-Scenarios: courier sorting lines, automotive assembly lines, airport baggage conveyor belts

-Load capacity: high (suitable for medium and heavy loads)

1. Non-Powered Roller Drives

-Passive response: no drive unit per se, the drum only provides support and rolling function, unable to move the goods autonomously.

-Represents scenarios: temporary racking in warehouses, lightweight material turnover areas

-Load capacity: low (suitable for light cargo)

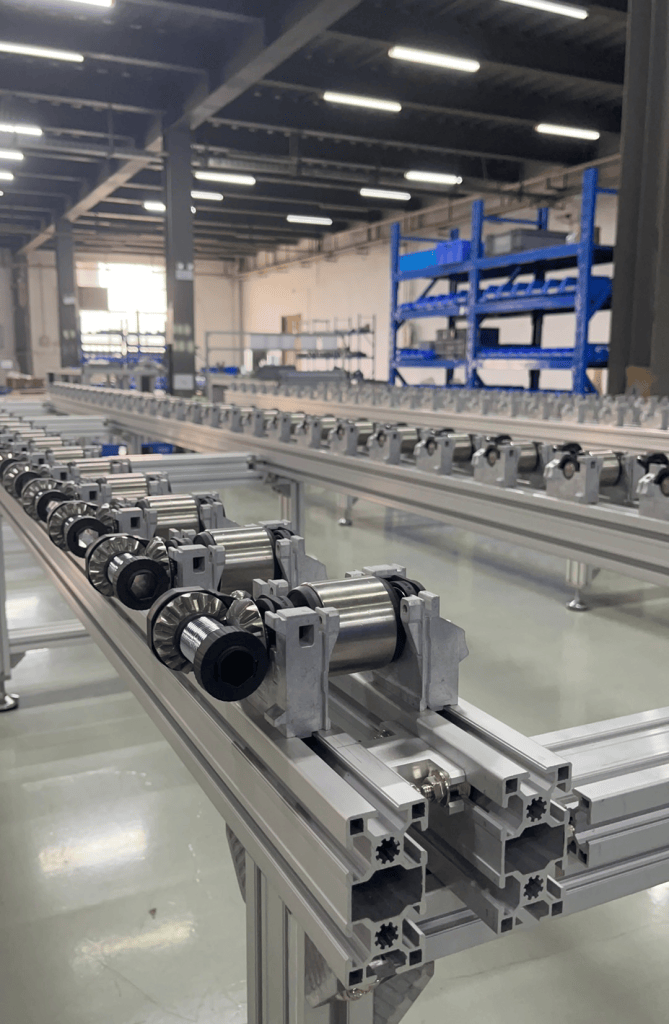

2. Accumulation roller

-Drive optional: the drive can be motorised or electric drum, the accumulation can be achieved electronically or by a block.

-Representative scenarios: staging areas for heavy materials, staging and diverting goods in logistics centres

-Load capacity: capable of driving heavier loads, suitable for heavy-duty material conveying.

III. Different application scenarios

1,Power Rollerconveyors

-Automated production lines: e.g. home appliance assembly lines, precise control of transport rhythms

-Long distance transport: airport baggage systems for efficient terminal coverage

Climbing/turning scenarios: self-powered to overcome gravity or complex terrain.

2,Non-Powered Roller Drivesconveyors

-Temporary warehousing: temporary storage area for goods, which can be pushed manually

-Lightweight sorting: e-commerce small parts sorting, reducing equipment costs

Space-limited scenarios: e.g. small workshops, space-saving installations

3、Accumulating roller conveyor

-Heavy duty material staging: In logistics centres or factories, it is used for staging heavy duty materials and adjusting the spacing or rate of items.

-Logistics centre diversion: a cargo staging and diversion area in the logistics centre to ensure orderly delivery of goods.

-Complex production processes: In complex production processes, it is used for staging and adjusting the rhythm of material transport to ensure production efficiency.

Wei Chuang Automation

As a professional manufacturer of intelligent conveying equipments, Weichuang Automation provides many types of conveying equipments. The products are made of high-quality materials and advanced manufacturing process to ensure the reliability and stability of the equipments, together with the tailor-made solutions, which can provide cost-effective combinations for all kinds of production scenarios. With the following advantages:

Product Performancestabilise::

All kinds of wire bodies are made of high-quality materials and advanced manufacturing process, which have high reliability and stability. The structural design of the chain enables it to withstand greater tension and wear, reducing the probability of failure.

Deliverability is efficient:

The short manufacturing lead time for modular conveyor lines allows for quick project delivery and avoids delays in the supply of equipment that can hinder the project schedule.

The service is professional and comprehensive:

Weichuang has rich experience in production line planning, can provide diversified products, but also can provide one-stop service for the peripheral support of the conveyor line, such as robot loading and unloading, tooling design and processing, lift device, etc., which really solves the customer's worries.

Market Recognition:

For more than 10 years, Weitron's conveyor systems have stood the test of time in thousands of automation companies' applications, distinguishing themselves from many competing products and winning the favour of many customers.