In today's rapid development of modern logistics and industrial automation, efficient conveying system has become the key to improve the productivity of enterprises. As an important part of the pallet conveyor system, with its high efficiency, flexibility and reliability, it is widely used in various industries. Today, let's learn more about one of the star products in the pallet conveyor system - theSpeed Chain Conveyor LineThe company will explore how it can help companies to automate their logistics upgrades.

l About Palletised Conveyor Systems

-relaxingHelping to be efficientbe in motion-

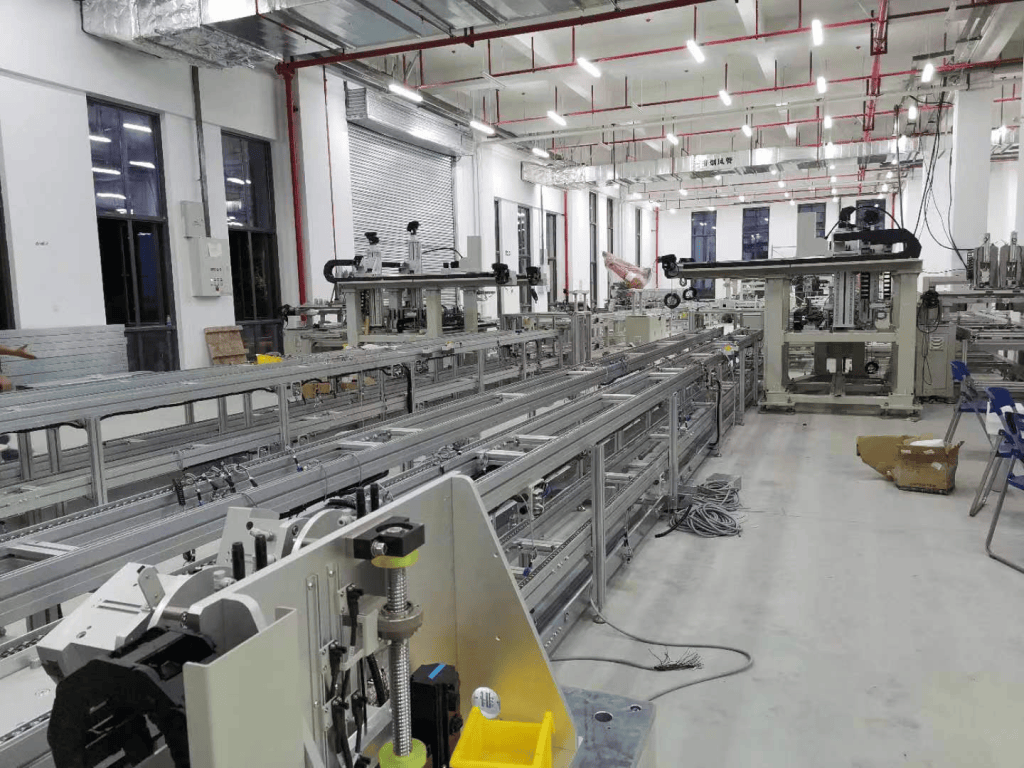

Pallet conveyor systems, also known as automated modular conveyor lines or modularPallet conveying lineIt is an important part of modern logistics equipment. It is mainly used in the field of logistics equipment, parts cache line, battery conveyor line, automation equipment and electronic product production.

The products are characterised by high efficient conveying, good adjustability, simple structure, reliable stability and strong adaptability.

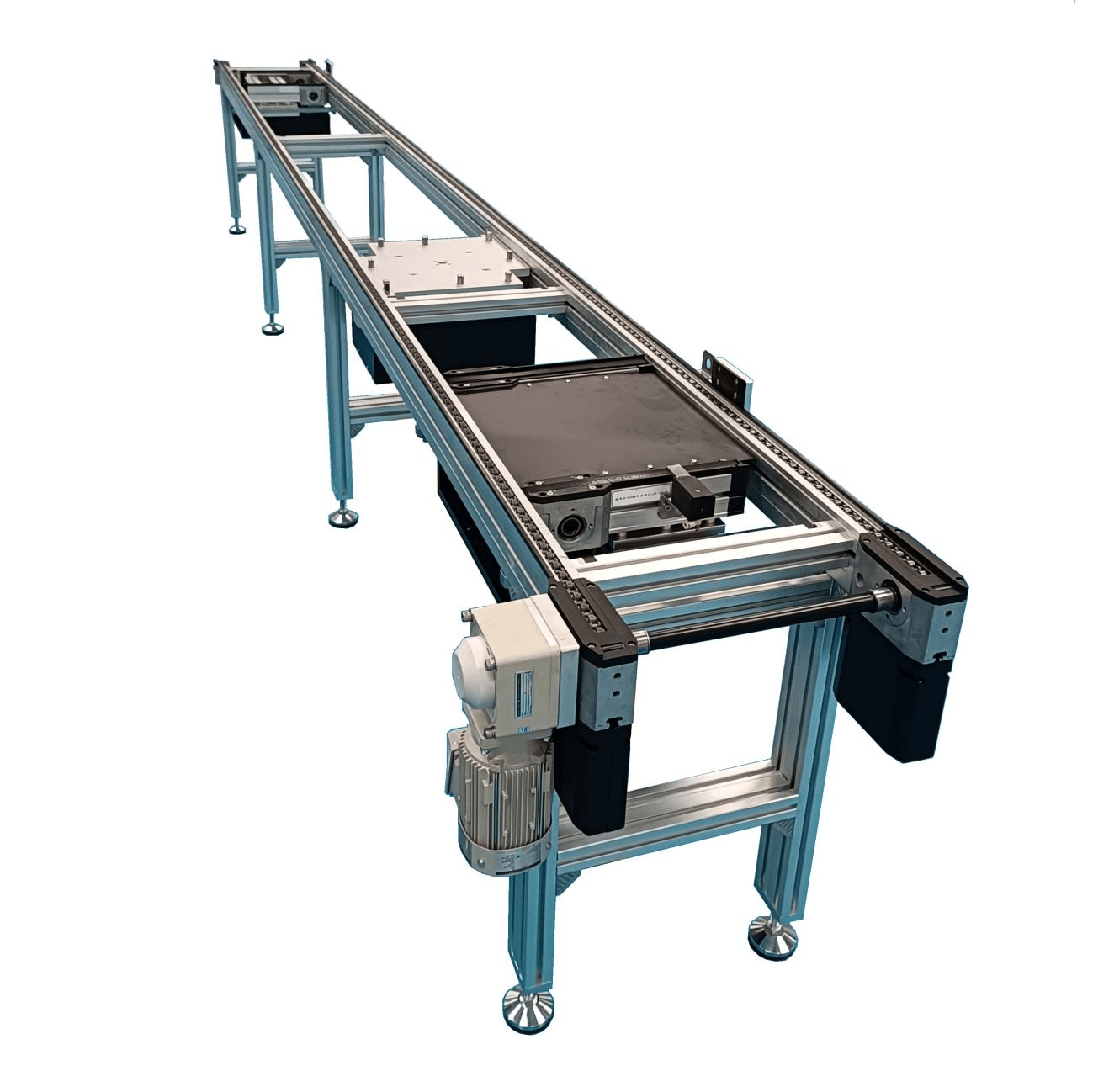

According to the division of conveying medium, there are three major types: chain type, belt type and roller type. Among them, chain type pallet conveying line is particularly suitable for conveying standard size pallets and larger box items with its strong loading capacity and high precision conveying performance.

l doubled speed chainCore advantages of the conveyor line

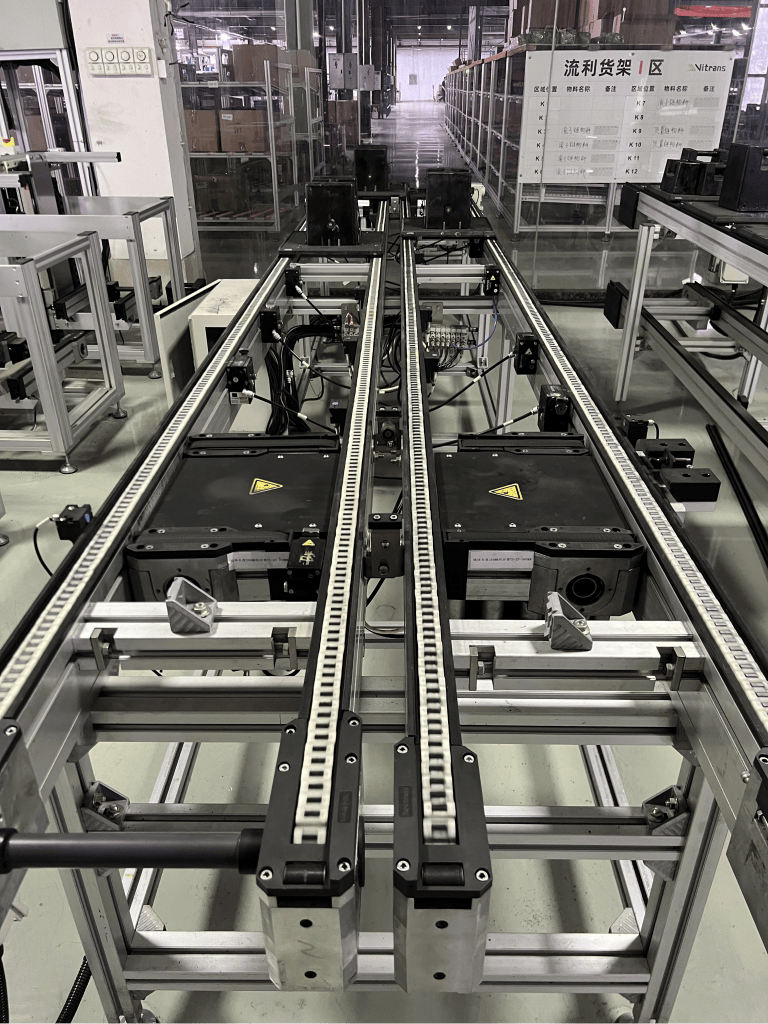

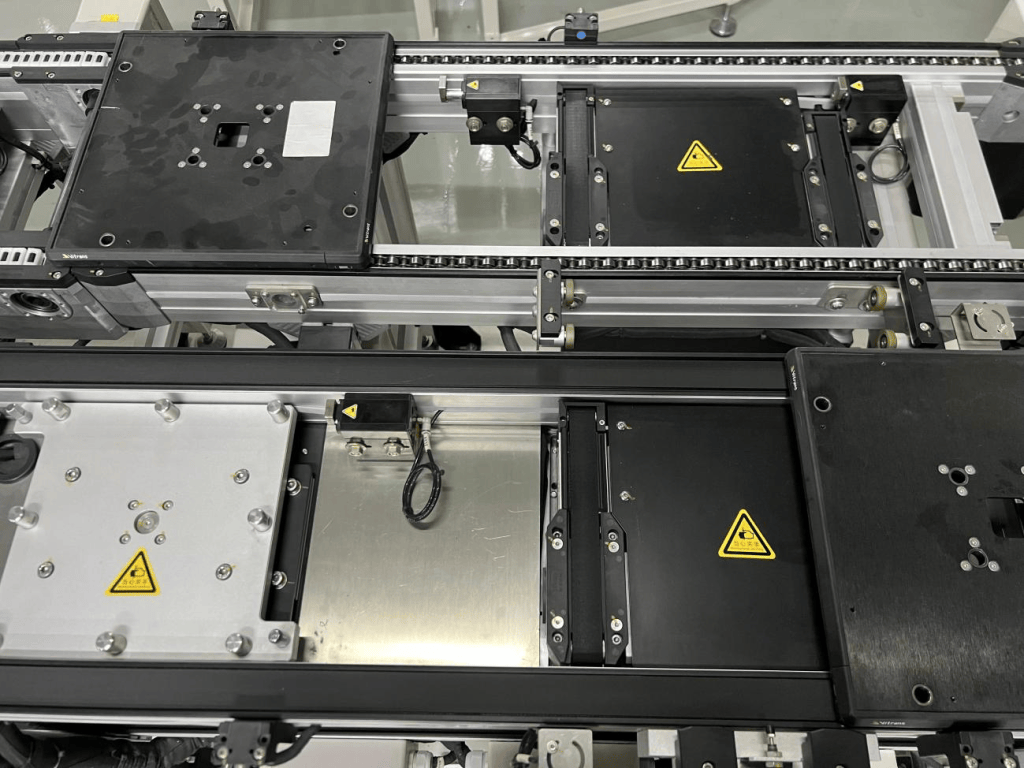

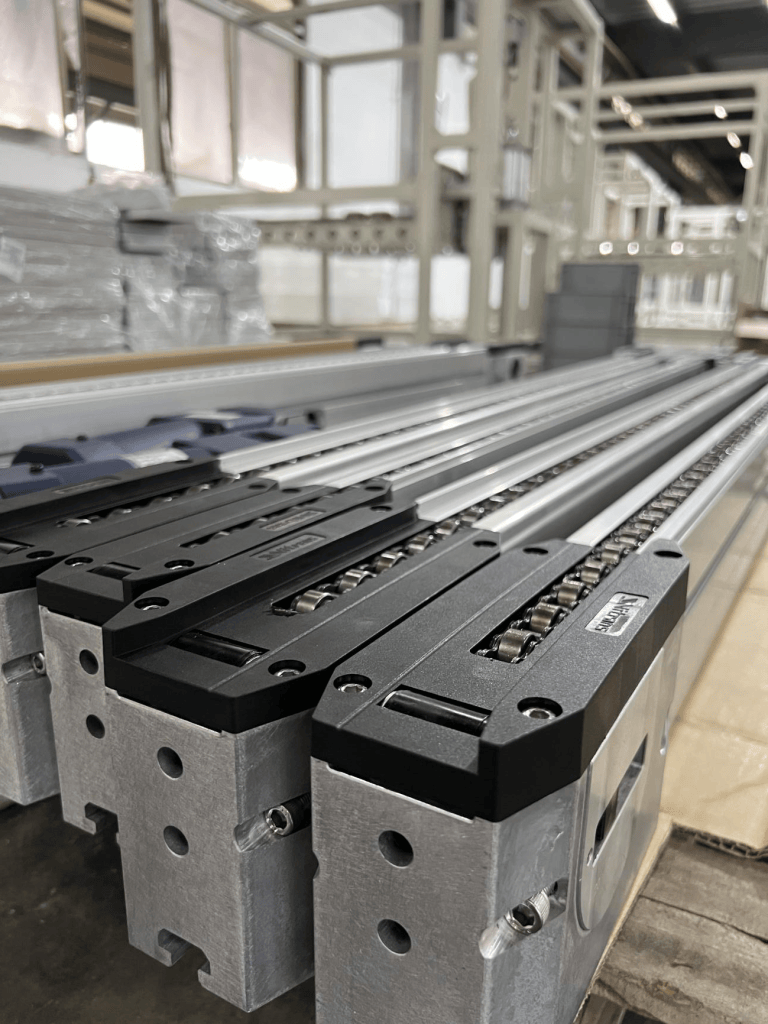

As a representative of chain pallet conveyor line, the speed multiplier chain is adopted as the core transmission component. Its working principle is to make the work plate carrying goods run quickly by the speed increasing function of the speed multiplier chain, and complete the complex operation of accumulating, shifting, transposing and transferring by the corresponding instruction.

The advantages of the multiplier chain conveyor line are:

–High conveying efficiency and stability:Able to operate stably in various harsh environments (e.g. high temperature, dust) to ensure the continuity of the production process.

–Precision synchronised conveying:Fast and accurate conveying speed ensures precise control of the production beat.

–Low noise and high durability:Smooth running, low noise and wear resistance significantly reduce maintenance costs.

Depending on the needs of the application, theSpeed Chain Conveyor LineA wide range of options are available, including 2.5x speed chain, 3x speed chain and single speed chain, and 08B or 12B speed chain can be selected according to the load requirement. Chain materials are available in nylon stacked roller chain and steel stacked roller chain.

l Courtesy of Wei ChuangTotal Solutions

Weichuang Automation is committed to providing customers with comprehensivepalletsConveying solutions that can meet the diverse needs of different industries.

Choose Wei Chuang, you will get:

Wide range of products:Certain inventory reserves to respond quickly to customer needs.

Competitive price and delivery time:Helping clients to dominate in the marketplace.

Ten years of experience:Ability to provide precise and customised solutions to our customers.

Excellent quality and service:We have established long-term relationships with many well-known manufacturers, and our quality and service have been recognised.

From automotive manufacturing to 3C electronics, from electric motors to the shoe industry, Weitron's solutions have been widely used in many fields.