As an indispensable part of modern automated production lines, pallet conveyor lines play a key role in material handling and flow. However, because of the different plant layouts, production line configurations and the diversity of product characteristics of each enterprise, the pallet conveyor line often needs to be personalized according to the actual needs of customization. How to realize the high efficiency and intelligence of the production line?

Here are a few points about customizationPallet conveying lineDetails and requirements that should be attended to when

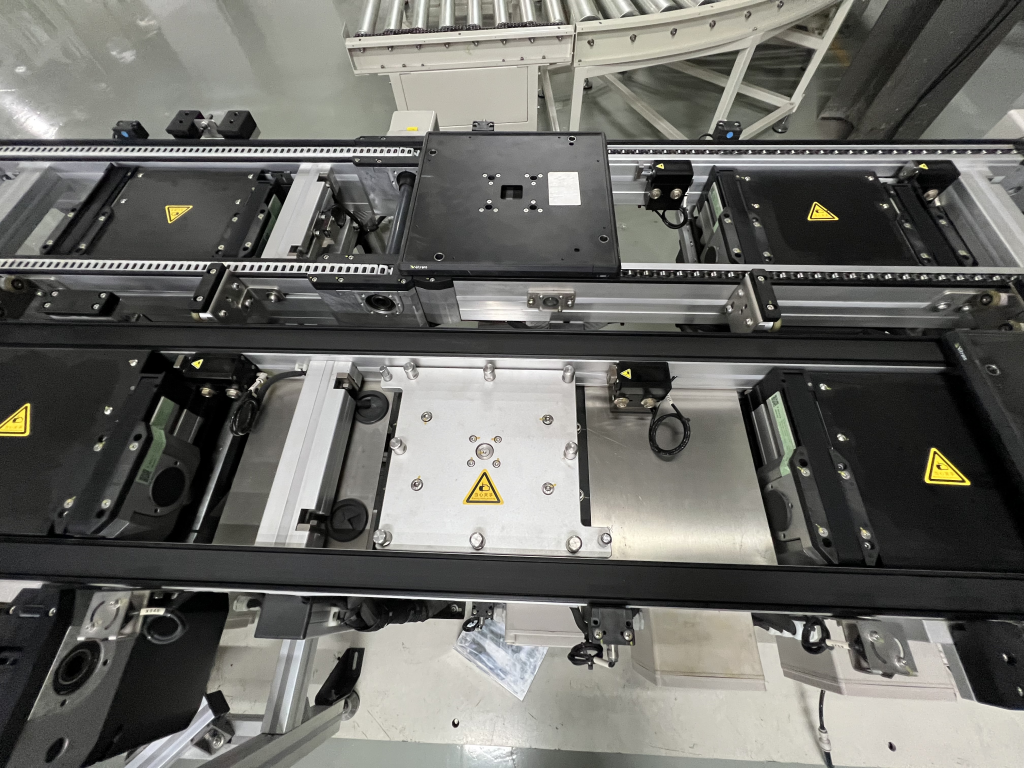

One,Load and pallet specifications

01load capacity

recognizePallet conveying lineThe load capacity of the conveyor line should take into account the weight of the product, the weight of the workpiece and the weight of the bottom bracket, and choose the appropriate type of conveyor line, such asroller conveyoror multiplier chain conveyor lines.

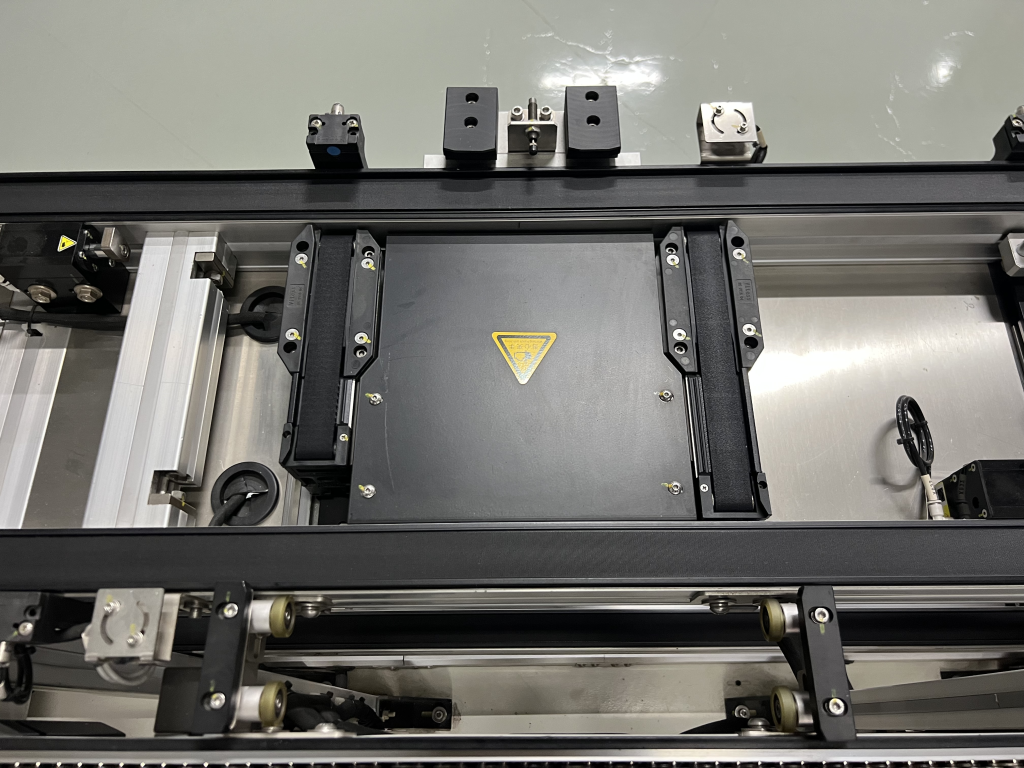

02Pallet Size

According to the product specifications, workpiece design and the size limitations of special mechanisms of the conveyor line (e.g., turns, elevators), the appropriate pallet size is selected to ensure interchangeability and versatility.

Second, the length and layout of the conveyor line

01length plan

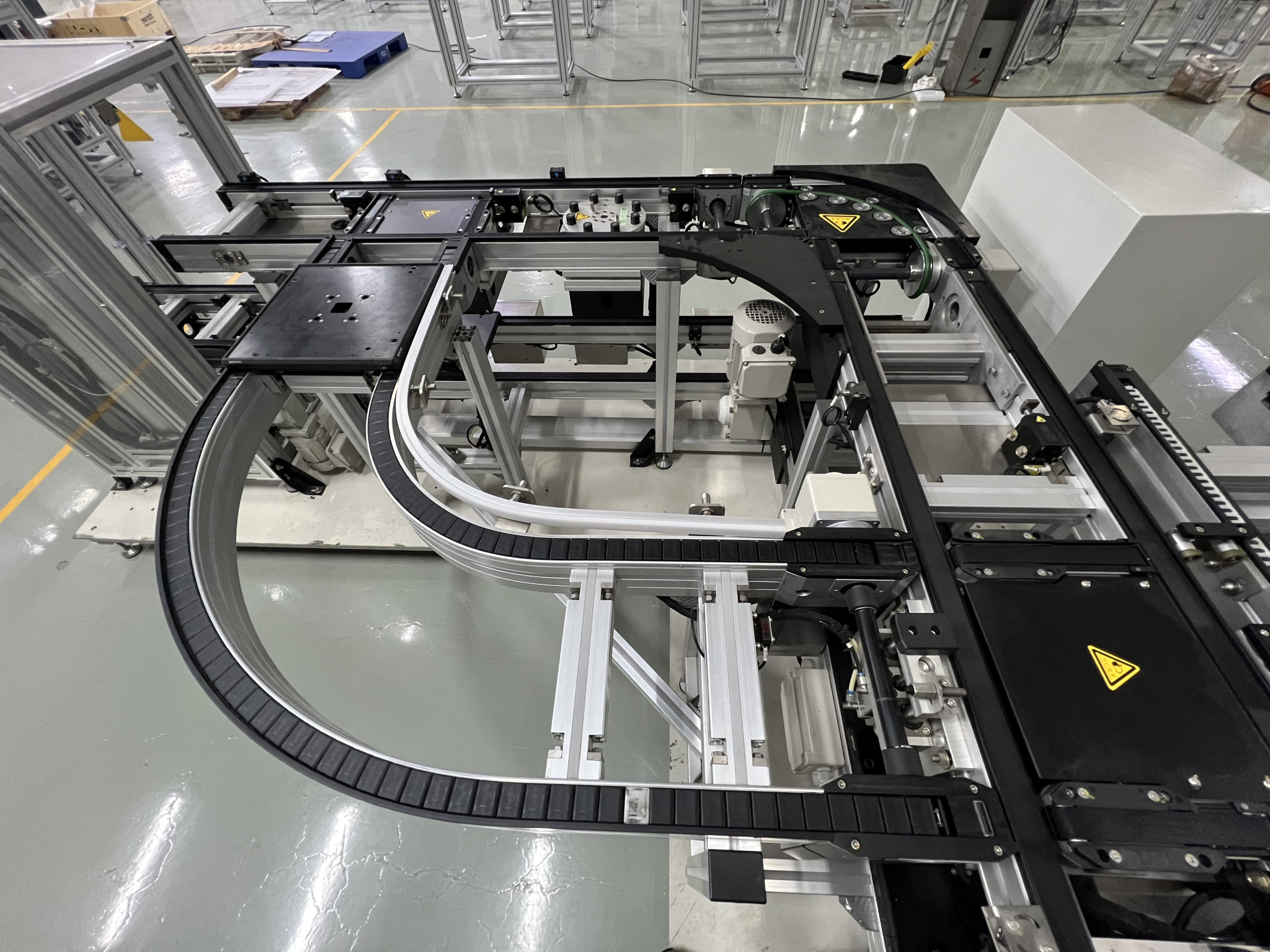

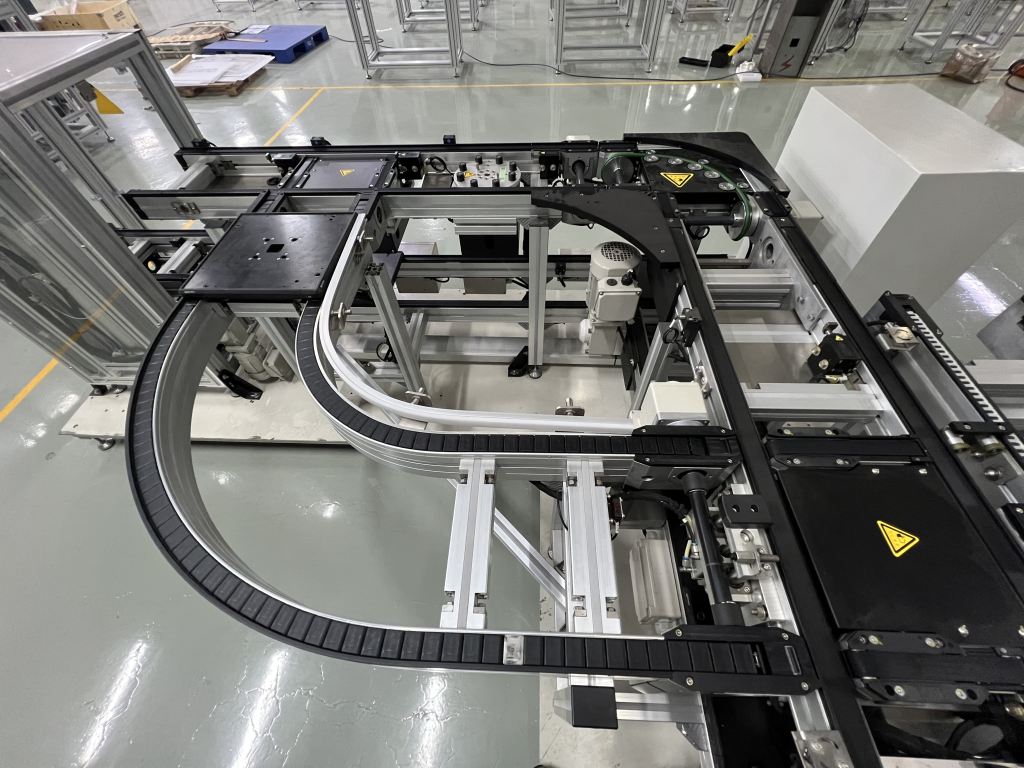

- Determine the starting point, end point and key node location through on-site measurement, combined with thematerial handlingCalculate the required conveyor line length for speed and beat requirements.

- Consider special terrain such as turns and climbs to ensure smooth operation of the conveyor line.

02Layout Optimization

- Optimize conveyor paths to reduce unnecessary conveyor distances and waiting times.

- utilizationmodular designRealize flexible combination and expansion to adapt to future layout changes.

Three,Height setting and ease of operation

01Height setting

- When setting the height, it is necessary to take into account the ease of material handling, the height of the operator and the stability of the conveyor line.

- Ensure that the conveying line is at the same height as the upstream and downstream equipment docking, and that the material flow is smooth.

02Ease of operation

- Installation of additional auxiliary facilities such as operating platforms, handrails and lighting fixtures.

- Through intelligent control to realize automatic start-stop, speed adjustment and fault alarm, reduce the intensity of operation.

IV. Selection of key components

01Media Type

groundMaterial CharacteristicsIn order to meet the requirements of the conveyor environment and load, select theTiming belts, flat belts, stacked roller chains或Plastic overhead chainand other conveying media.

According to the material weight, conveying speed and workshop environment to choose the architecture material, such as steel, stainless steel or aluminum profile.

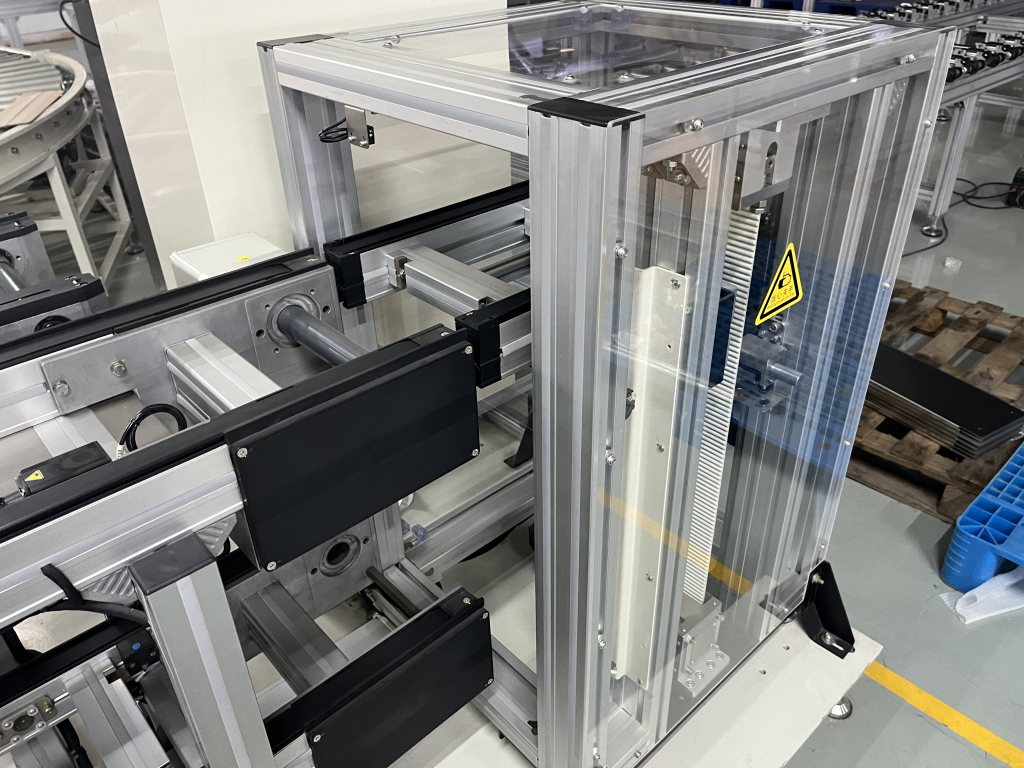

03Functionality Expansion

- Additional functions such as stoppers, jacking positioning units, etc. are added on request.

- In special environments (e.g. high temperature, humidity), install appropriate protective measures.

五Key implementation points

01Parameter clarity

Precise data on size/load/speed etc. is required.

02Supplier Selection

Choose manufacturers with rich industry cases and technical strength to ensure product quality and after-sales service.

03Acceptance testing

Positioning calibration and load continuous operation tests are required.

04Personnel training

Train operators in key operations such as start-stop, emergency stop, and fault reset.