doubled speed chainWhat are the components of a conveyor line?

1. Chain (doubled speed chain)

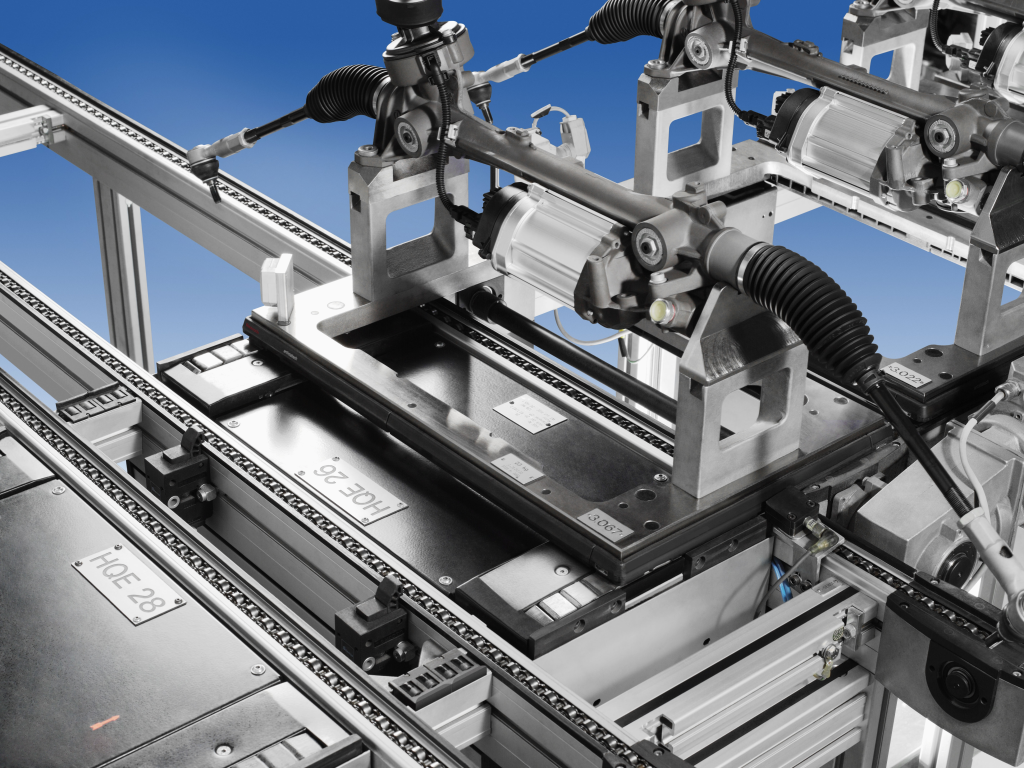

With a specially designed roller structure, usuallySingle Speed Chain2.5x speed or 3x speeddoubled speed chainIt is designed to produce differential speed effect when the rollers contact with the guide rail, so that the speed of the carrier is higher than the speed of the chain itself. The material is generally high-strength alloy steel or stainless steel, with wear-resistant and corrosion-resistant characteristics.

Power is provided by a drive motor, usually an independent three-phase geared motor drive.

3. Support structure guide and tensioning mechanism

Support structure guide rail (track): aluminum alloy or steel guide rail to support the chain and guide its running direction, the surface should be treated with low friction.

Tensioning device: It is used to adjust the chain tightness to prevent the chain from slipping or coming off.

4.Carrier work plates (pallets)

The platform that carries the workpiece, also known as a workpiece tray, can be customized by the manufacturer, the material is usually PVC, and aluminum can be used for large loads.

5. Blockingstopping body((Stopper)

Blockers for positioning, sorting or pausing of workpieces, controlled in linkage with sensors.

6.Anti-kickback mechanism((blocker)

The main purpose is to avoid the rebound of the workpiece plate after the blocking of the workpiece plate, which can only move forward and not backward, also known as the check back mechanism.

7. Jacking mechanism((jacking traverse)

The role of the jacking mechanism is mainly, to improve the positioning accuracy, to avoid the assembly precision is too low.

8. Lift and return mechanism((Elevator)

bilayerdoubled speed chainAll are required to pallet return, the upper conveyor material assembly lower pallet return, return need two lift return mechanism, that is, our elevator.

Application Scenarios for Speed Chain Lines

Speed Chain Conveyor LineSuitable for a wide range ofAutomatic production linescenarios, especially excelling in areas where high speed conveying and high efficiency are required. Key applications include:

- Electronics industry:For example, the core assembly section of the lithium-ion battery industry ensures fast and accurate material handling.

- Automotive Industry:It covers the production of accessories for new energy battery assembly lines and automotive painting, and supports heavy load transfer.

- Appliance Manufacturing:For example, assembly lines for air conditioners and washing machines improve assembly efficiency and reduce labor costs.

- Other areas:This includes the electrical appliance industry or the motor industry with high cleanliness requirements for customized conveying needs.