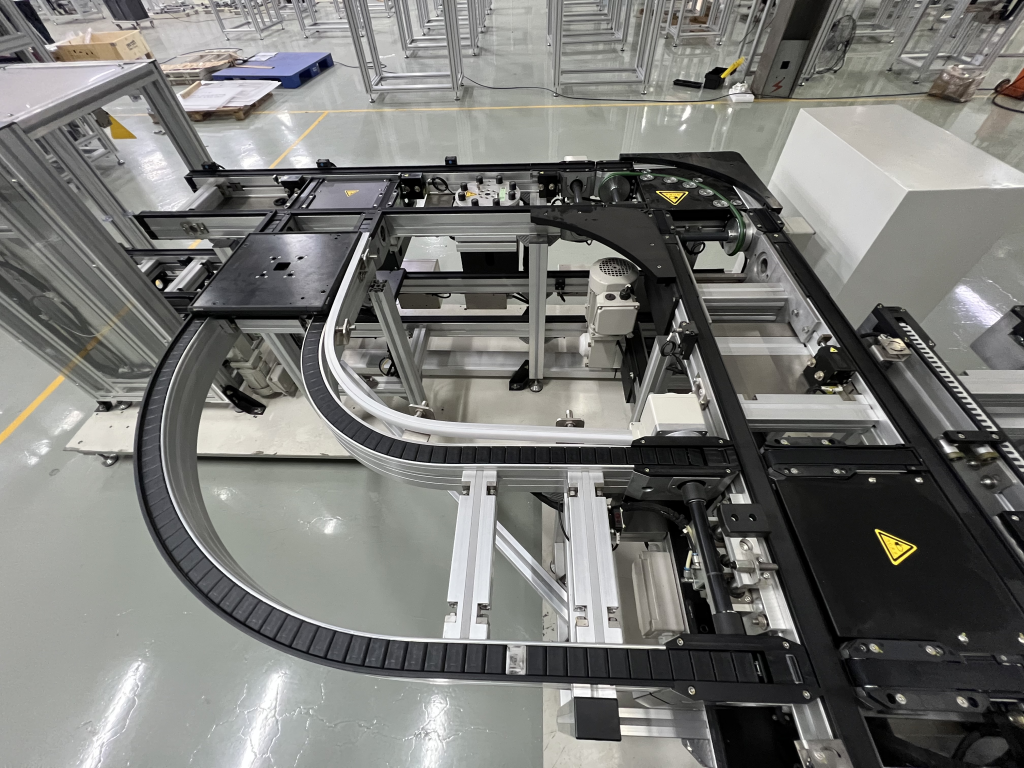

In the arena of modern industrial production, theModular Conveyor SystemsIs an indispensable protagonist, through the efficient operation of the function, can be organized and coordinated all kinds of materials conveying work. In this protagonist of the many “competent generals”, elevator is undoubtedly an indispensable role. Today, let us get closer to the hoist, to understand its classification and key role.

One,What is a hoist?

Simply put, the hoist is like the “elevator” in the industrial world, its main task is to lift materials from one height to another. In a modular conveying system, the hoist can be a key equipment to realize vertical transportation of materials, which can make materials circulate smoothly between different floors or different heights of production.

Two,palletselevationThree classifications of machines

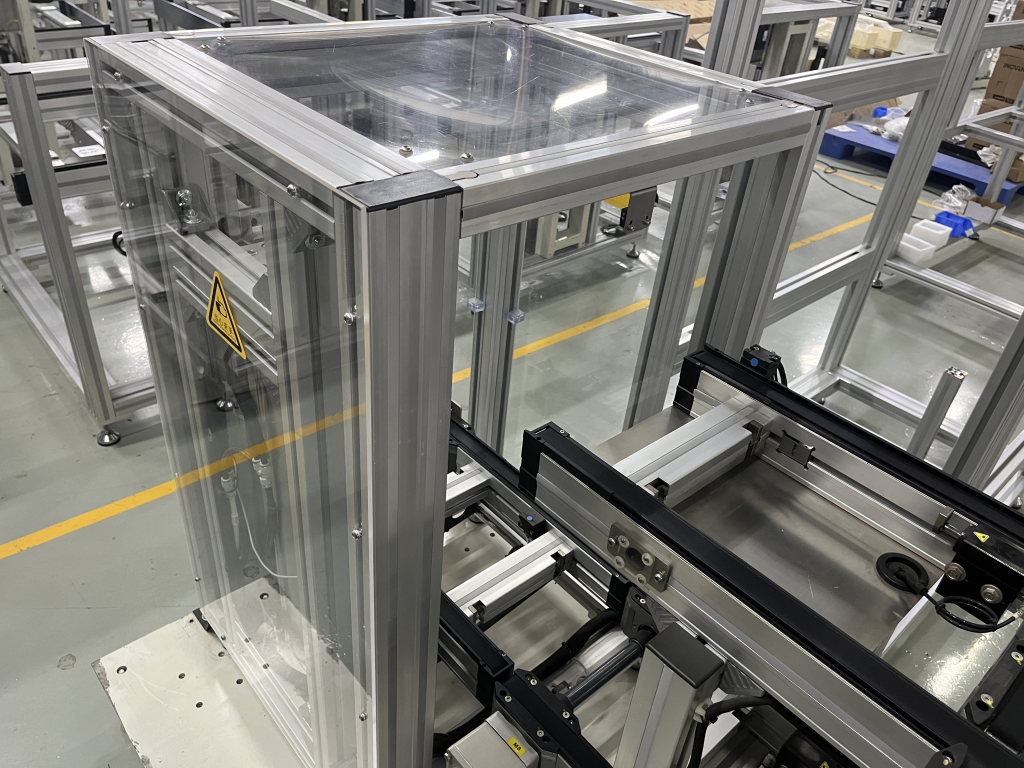

l Synchronous belt elevator

Synchronous belt elevators utilize servo motor drives and are suitable for pallet conveying between double or multi-layer lines. It runs smoothly and with low noise, and can accurately control the lifting position and speed. It is more suitable in occasions with high requirements for transportation accuracy and stability, such as the production line of electronic products.

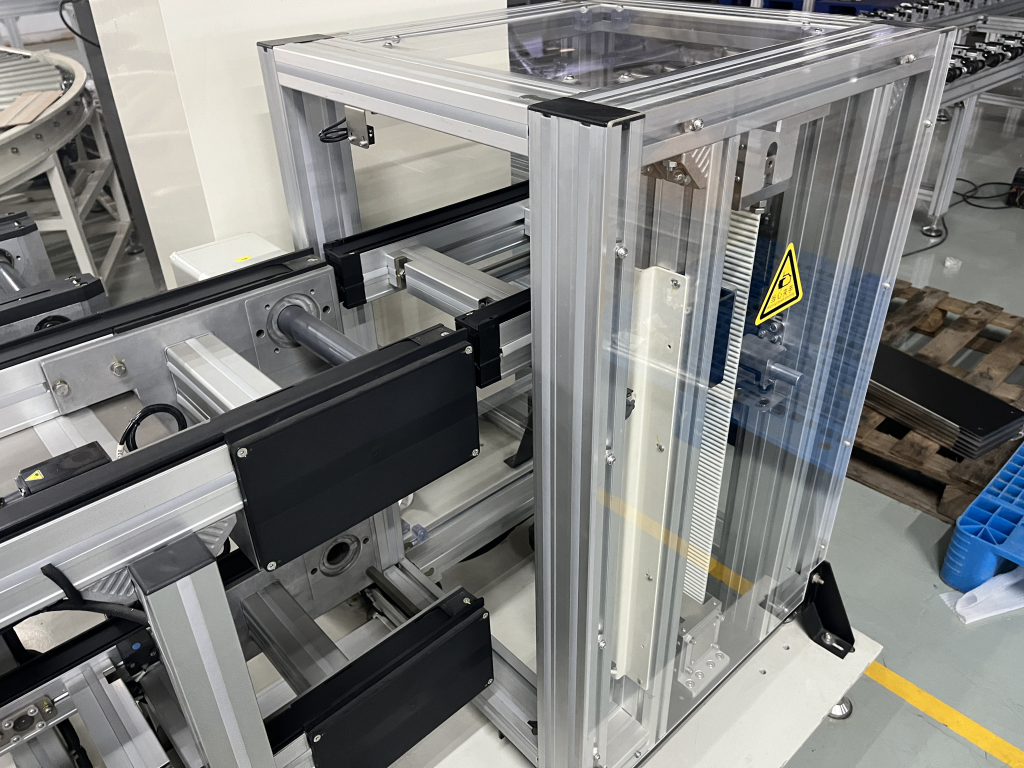

l Screw jacks

This hoist is powered by a rodless cylinder, specially designed for double-layer wire bodies. Although a little slower, it has a simple and reliable structure and also supports a maximum load of 30kg. Particularly suitable for limited spaceDouble Conveyor System。

l Rodless Cylinder Lifter

Rodless cylinder hoists have no traditional piston rods, are compact and responsive, and can perform lifting and lowering actions quickly, excelling in automated production environments where efficiency and space utilization are pursued.

Three,The role of hoists in modular conveyor systems

1,Realization of material transportation with height difference

In a factory, different production processes may be at different heights. Elevators make it easy to get materials from lower to higher places, or vice versa, making the whole production process coherent.

2,Improvement of production efficiency

Elevator can quickly and accurately complete the vertical transportation of materials, reducing the time and labor intensity of manual handling, production efficiency is naturally greatly enhanced.

3,Optimization of spatial layout

By transporting materials vertically, hoists allow factories to make full use of vertical space, resulting in a more compact and rational production layout.

4,Guaranteeing production continuity

The elevator stabilizes thematerial handlingto each production link, avoiding production interruptions due to untimely supply of materials and ensuring the continuous operation of the production line.

Hoists may be small, but they do a lot. It is with these different types ofhoistThe modular conveying system can operate so efficiently and stably, and play its own strength for the development of industrial production.