In industrial production, the handling of heavy workpieces that can easily weigh thousands of kilograms has always been a problem. AndHeavy Duty Conveyor Linescame along and solved this pain point perfectly. Find out today from theWorking PrincipleFour aspects, features, advantages and application industries, to bring you a comprehensive understanding of it.

One,Working Principle

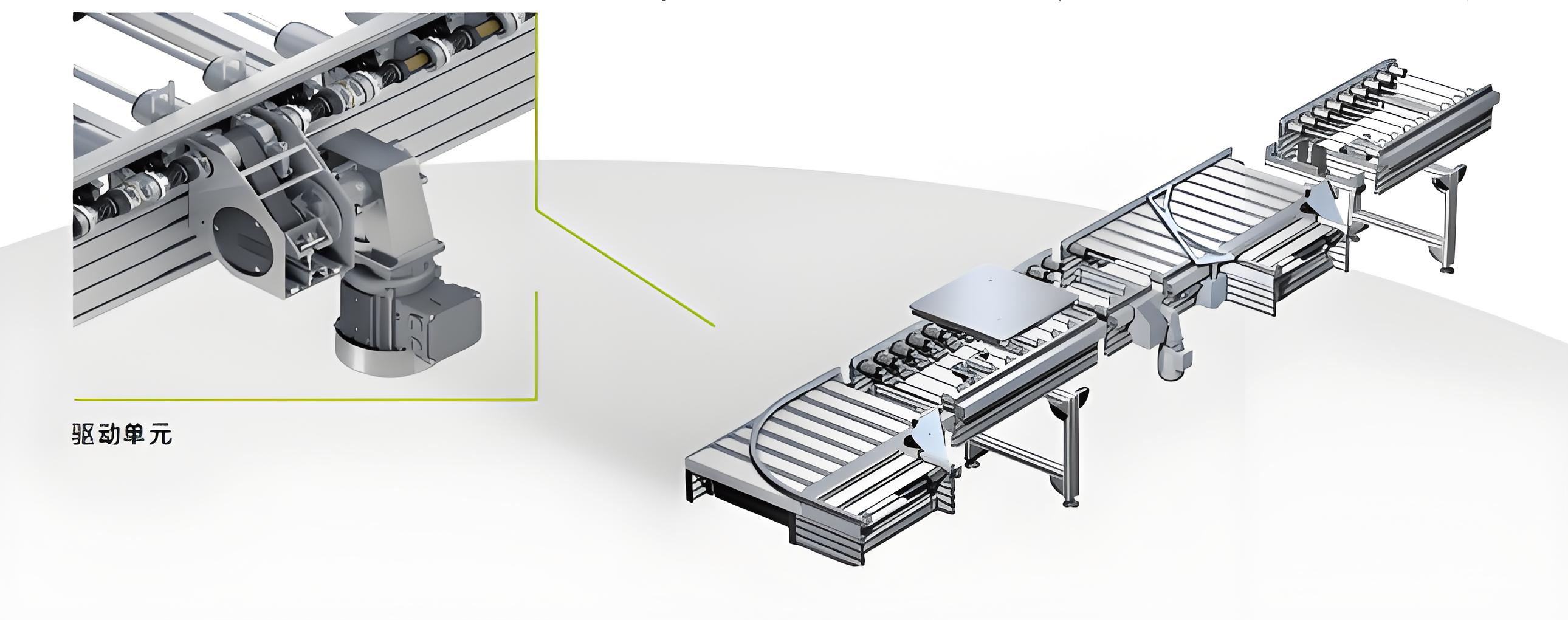

Heavy-duty conveyor lines are not a single piece of equipment, but are made up of severalmodular componentSystems that work in tandem.

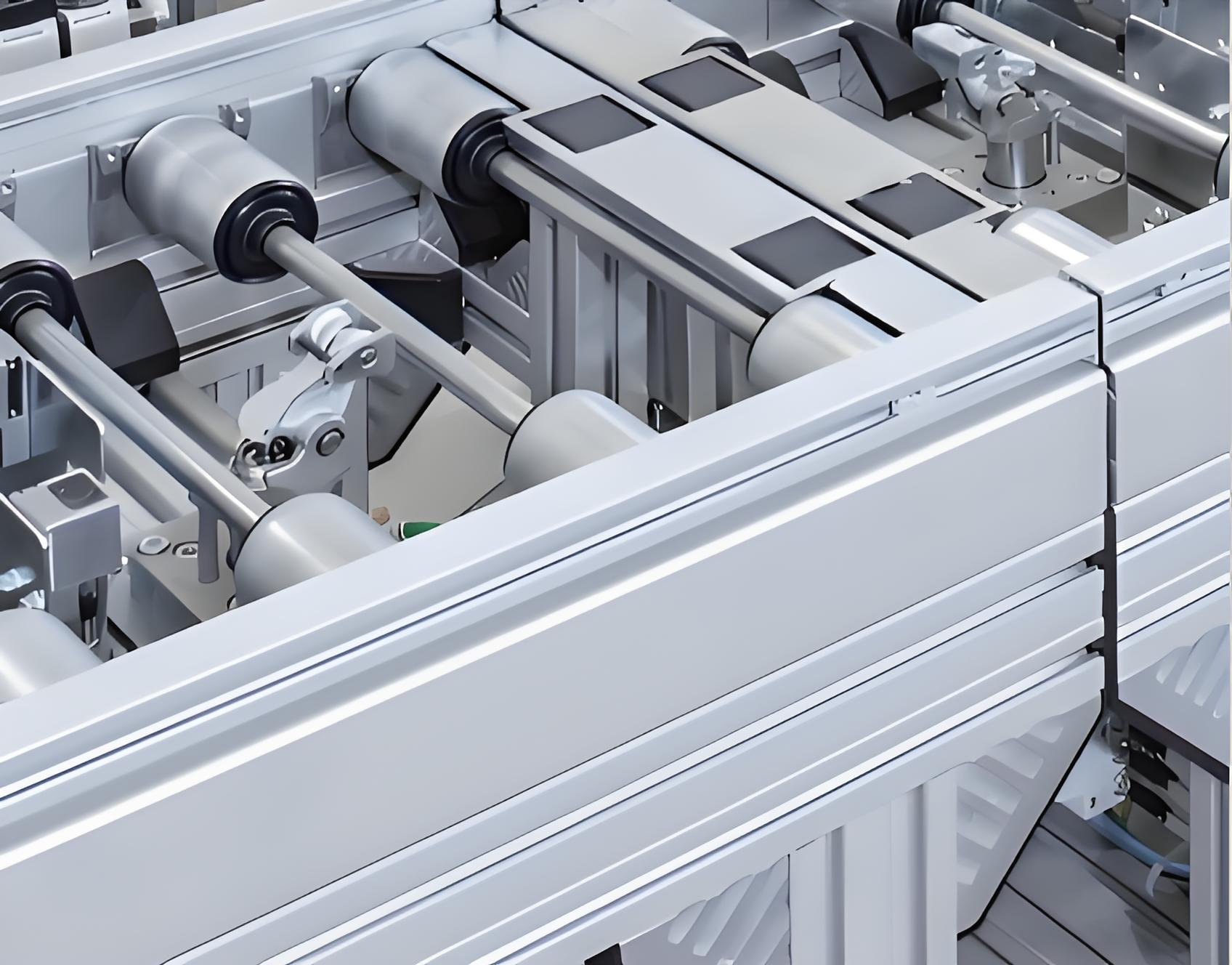

1,core driverThe bevel gear spindle, which is located in the shield underneath the conveying surface, drives all the rollers to rotate synchronously to provide power for heavy load conveying.

2. The workpiece is placed on a special pallet.pass (a bill or inspection etc)drum sectionfunnelWhen encountering scenes that require steering, lifting or positioning, the rotating unit, lifting unit and positioning unit will accurately cooperate. For example, the jacking and positioning unit can jack up and fix the pallet, and the repeatable positioning accuracy can reach ±0.3mm.

3. The whole process consists ofTransportation control componentsIntegration can also be achieved by shuntspalletsThe branch conveyor is flexible enough to cope with different production requirements.

II. Heavy-duty conveyor linesspecificities

1,modular design

是Heavy Duty Conveyor LinesThe biggest highlight of the drive module, workpiece tray, and various functional units can be freely combined, and also supports non-standard customization, which is efficient from planning to installation and commissioning.

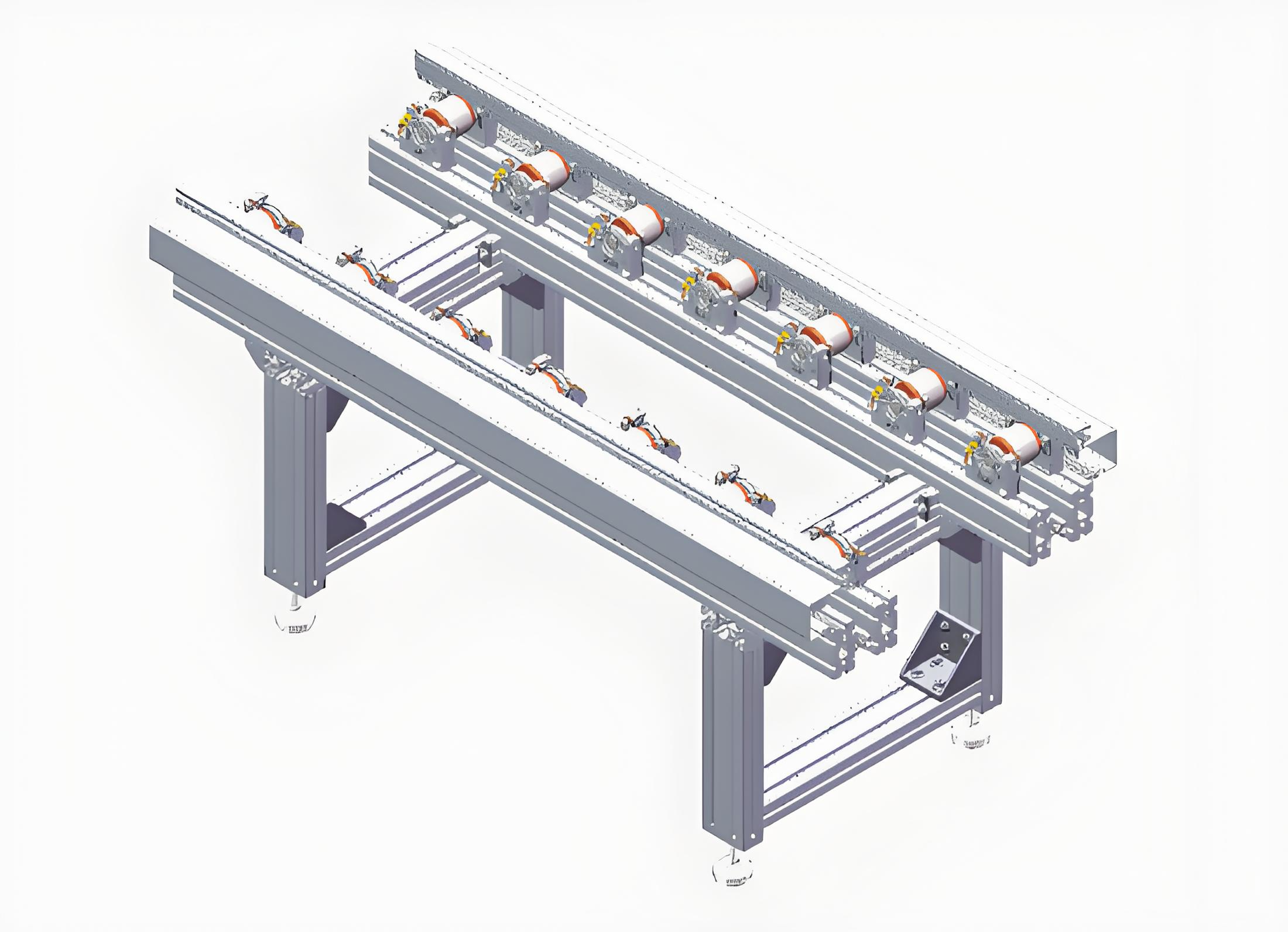

2,carrying capacity强

Transportation of loads of up to 4000 kg and more with rollersStainless steelThe wire body is made of high-strength aluminum profile, which is sturdy and durable.

3,Easy maintenance

The bevel spindle drive reduces the need for lubrication and some components can be manually adjusted, for example by removing the spindle guard to adjust the friction.

Three,comparisonCommon Conveyor Line'sdominance

Heavy-duty conveyor lines have obvious advantages over common chain-driven conveyor lines:

- Quieter operation without the noise of chain drive, making the workshop environment more comfortable.

- Higher energy efficiency and low drive power requirement saves a lot of energy costs in the long run.

- It is more adaptable, supports all-weather use, and can also divert traffic in both directions. The drive unit can be installed on either side for more flexible layout.

- Fast turnaround time and standardized components shorten the delivery cycle and enable quick response to production needs.

Four,Application Sectors

①Automobile manufacturing industry

It is used for handling heavy parts such as automobile chassis and engines, and realizes precise conveyance on the production line.

②Heavy machinery industry

Carrying large mechanical parts and helping assembly, testing and other processes to be carried out efficiently.

③Warehousing & Logistics

Handle the in/out and sorting of heavy goods to improve the efficiency of warehouse operation.

Heavy-duty conveyor lines have become an indispensable piece of equipment in industrial production thanks to their powerful performance. If your business has heavy-duty handling needs, consider this modular solution that facilitates better matching of production needs.