Small Belt ConveyorAs the core conveying unit of the assembly line, it can be matched with different functional devices to realize the whole process of automation or semi-automation operation, such as material positioning, inspection, assembly, sorting and so on. Specific matching programs need to be designed in accordance with the core requirements of the assembly line (e.g., precision, speed, degree of automation). The following are common matching devices and application scenarios categorized by functional module:

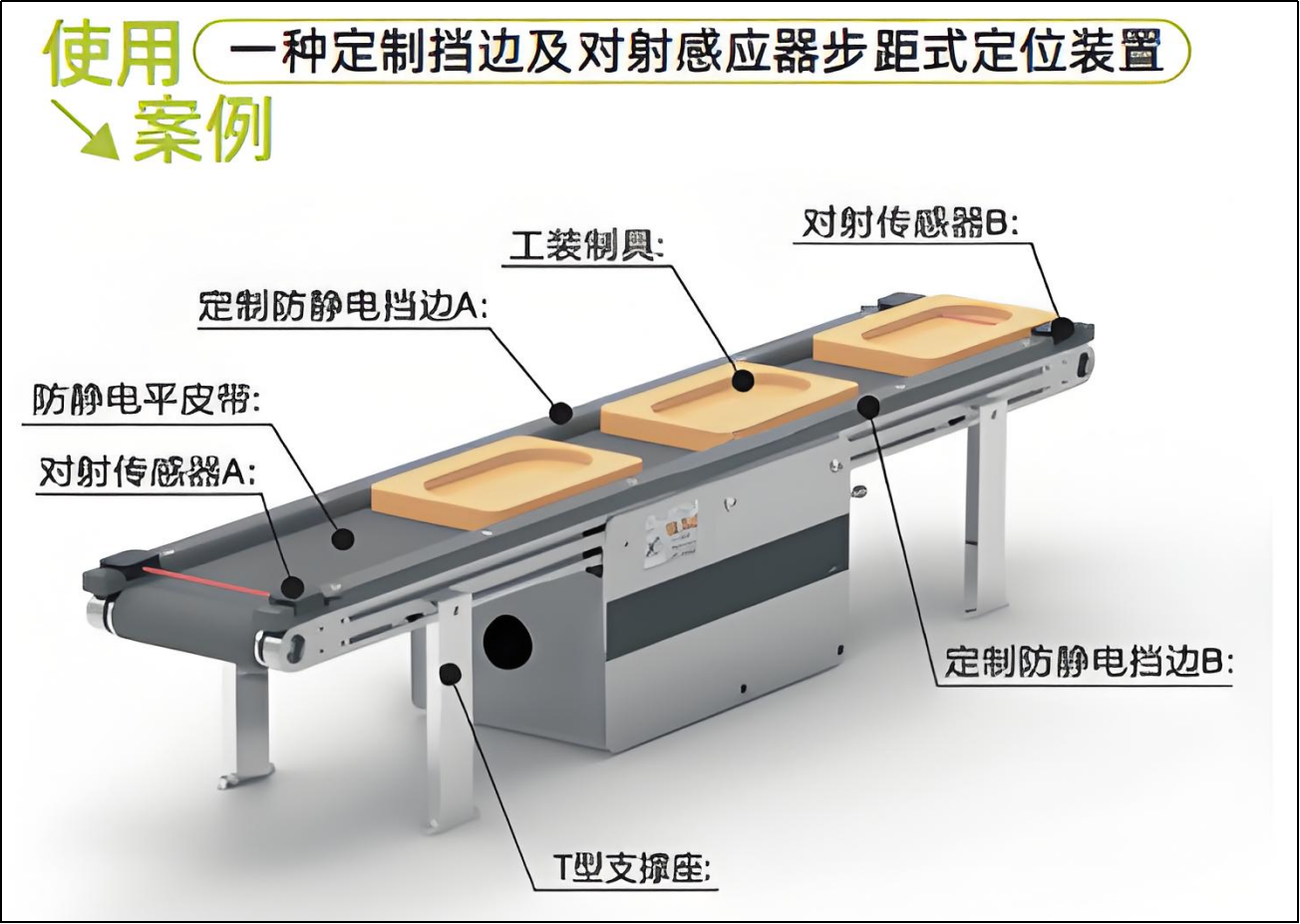

One,Material positioning and guiding devices

minor worksbelt conveyorThe conveying speed is slow, but the assembly operation requires the material to move in a fixed position or in a directional way, so it is necessary to match the positioning/guiding device to avoid the material from shifting.

| Device type | core functionality | Applicable Scenarios | Key Features |

| Side guide plate | Baffles along both sides of the belt to limit lateral deflection of material | Conveying of regular shaped materials (e.g. boxes, parts) | Simple structure, adjustable baffle spacing to suit different material sizes. |

| Positioning stopper | Pneumatic/mechanical stops on the side or underneath the belt to temporarily hold back material. | Stations where assembly needs to be suspended (e.g. screwing, labeling) | Can be linked with sensors to realize stop-on-demand. |

| centering mechanism | Inclined guides on both sides gradually narrow to straighten the material to the center of the belt. | Scenarios requiring high centering accuracy (e.g., parts docking, inspection) | No need for power, rely on the inertia of the material itself to complete the centering. |

| Belt locating pins | Raised pins embedded in the surface of the belt to catch the bottom locating holes of the material | Materials requiring strict attitude fixation (e.g., perforated parts, tooling boards) | High positioning accuracy (within ±0.5mm), customized belts required |

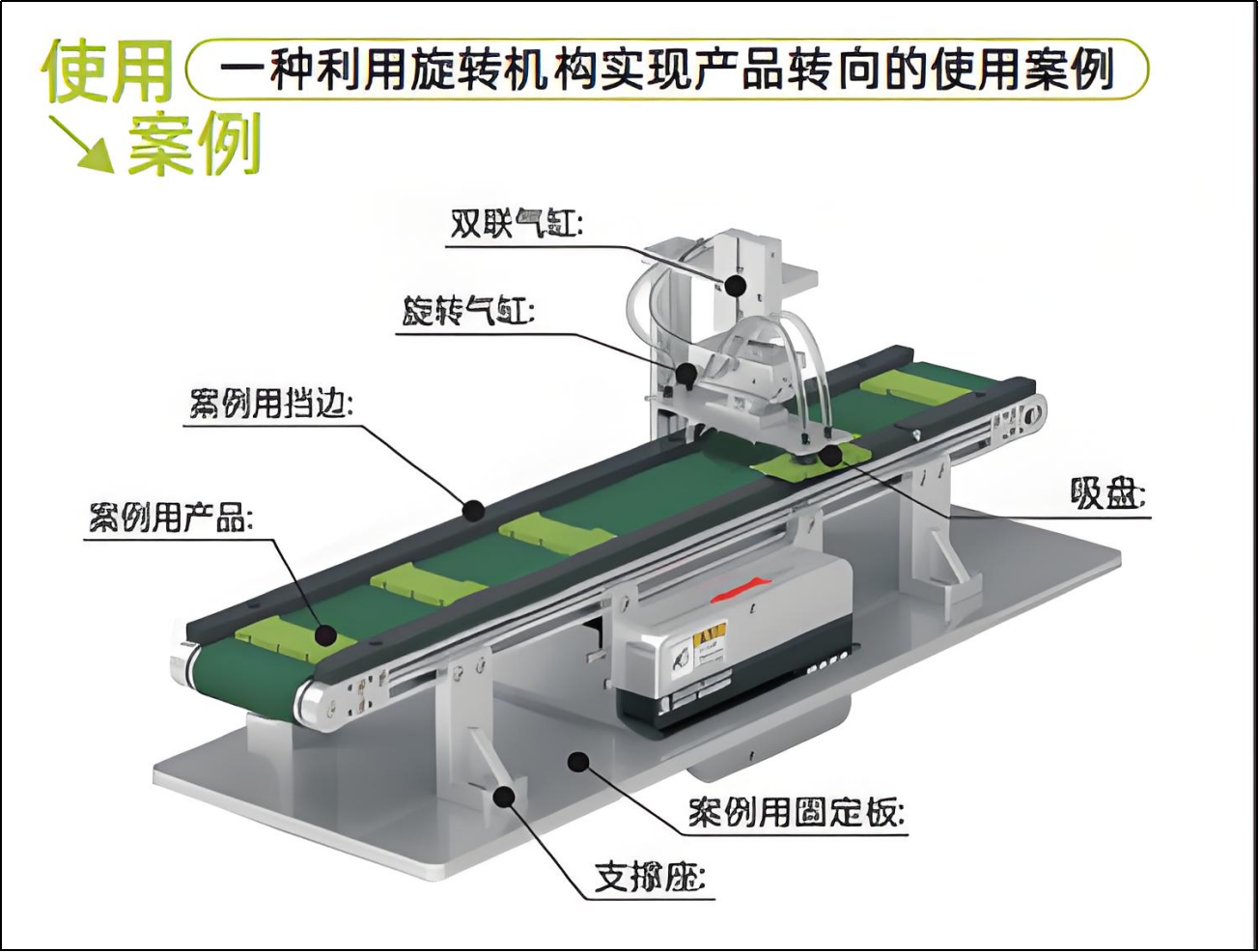

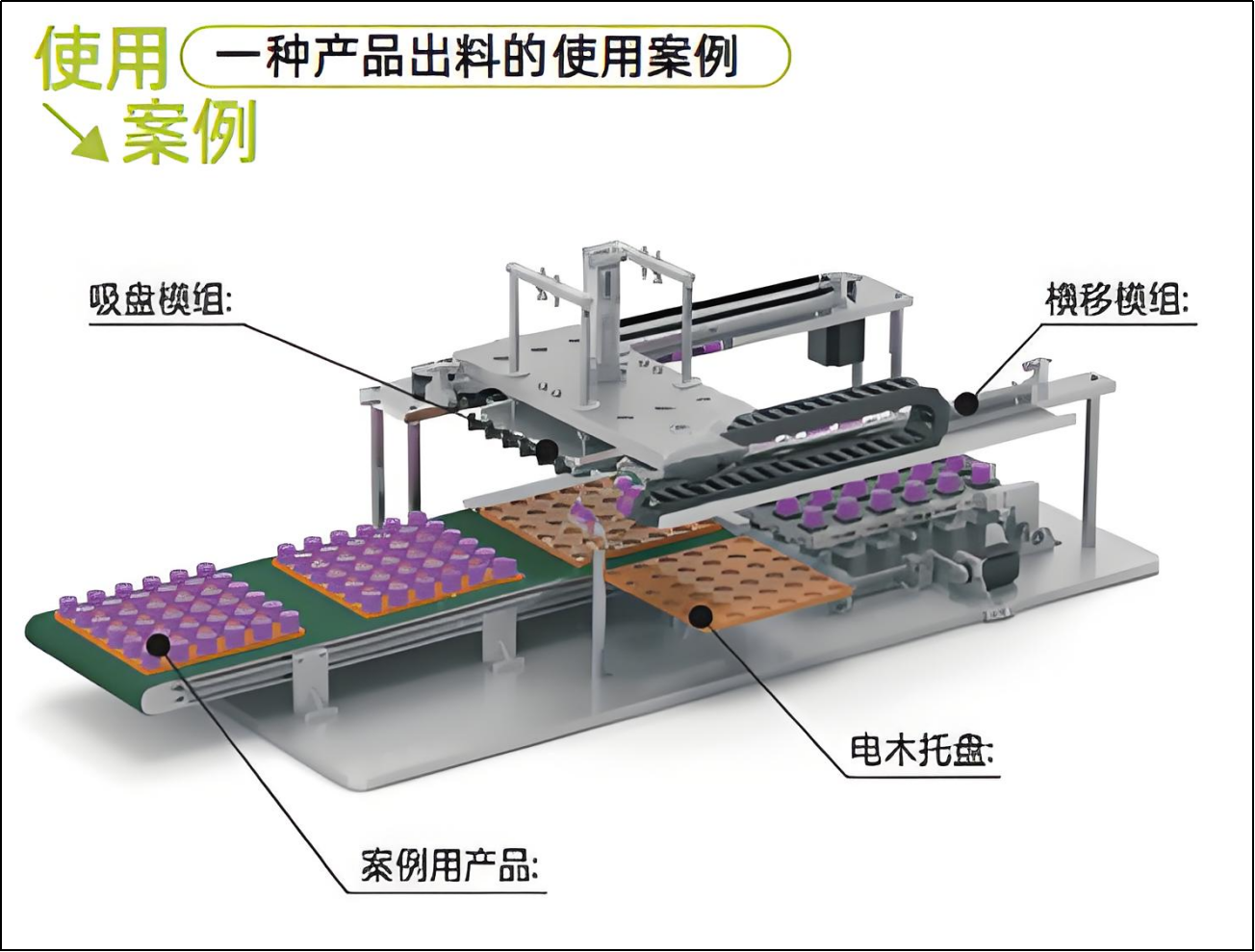

Two,Material transfer and assembly devices: realizing process convergence

The assembly line needs to complete the action of material gripping, handling and assembling during the conveying process, and it needs to be equipped with robotic arm or pneumatic mechanism to connect the operation of different work stations.

1,Small Cartesian Coordinate Robot Arm

- Function:Moves along the X/Y/Z axes to complete the action of gripping materials → placing them in the assembly position → assembling the parts (e.g. screwing screws into the parts, embedding fittings into the main body).

- Advantage:Lower cost than multi-jointed robotic arms, suitable for simple repetitive movements, and can be fixed directly to a stand next to the conveyor.

- Applicable Scenarios:Small parts assembly(e.g., electronic components, toy parts).

2,Pneumatic jaws/suction cups

- Function:Driven by compressed air, it clamps hard parts (jaws) or adsorbs light materials (suction cups, e.g. plastic sheets, film).

- Way to go with it:Linkage with positioning stopper - when material is in place the stopper is stuck and the clamping jaws/suction cups move synchronously to complete the transfer or assembly.

- Applicable Scenarios:Short distance transfer of lightweight materials (weight <5kg).

3,Lifting platforms

- Function:Mounted below the conveyor to lift material above theleather beltThe height is convenient for gripping by the upper robotic arm, or articulating the upper and lower conveyors.

- Type:Pneumatic lifting (fast speed), electric lifting (high precision).

- Applicable Scenarios:Multi-layer assembly lines, stations that need to be lifted for assembly (e.g. bottom screwing).

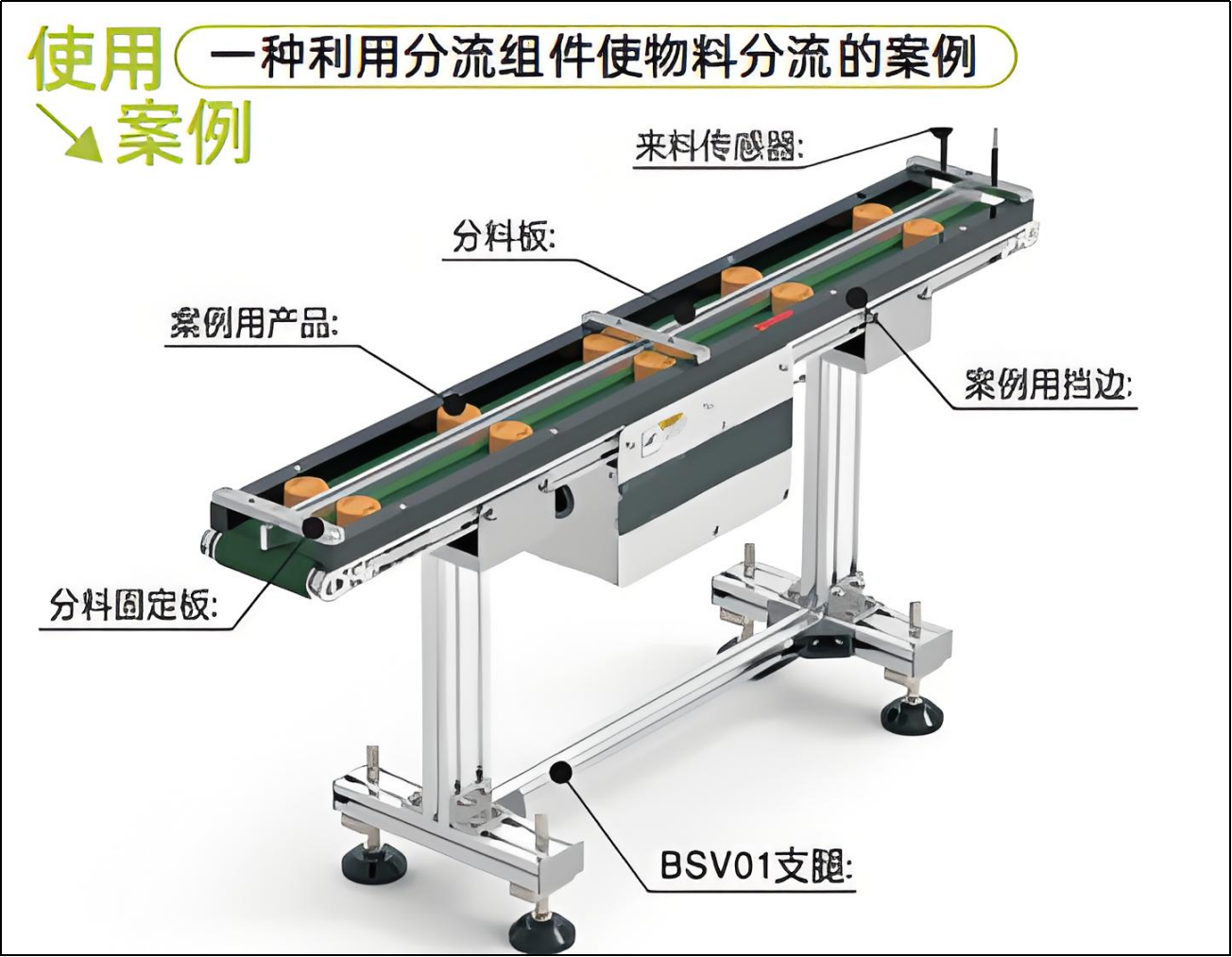

Three,Detection and screening devices

The assembly process needs to check for missing parts, unqualified dimensions, and incorrectly assembled products, which need to be matched with detection devices to realize automated screening and reduce manual intervention.

| Device type | core functionality | working logic | Applicable Scenarios |

| Photoelectric sensors | Detecting the presence/availability of materials and missing parts | The sensor emits light and triggers a signal when the material is obscured, determining whether it meets the have/have-not requirement. | Check for missing parts (e.g., missing instructions in the box). |

| Visual Inspection Camera | Capture material images and compare to standard templates to identify dimensional/appearance defects | Camera fixed above the conveyor, real-time capture → software analysis (e.g., whether the parts are mounted upside down, whether there are scratches on the surface) → output pass/fail signals | High-precision inspection (e.g., electronic component pin spacing, printing pattern alignment) |

| Weight sensors | Checking the weight of materials to determine whether there are missing parts (e.g., missing screws) | A weight sensor is installed under the belt section, and a standard weight range is set, beyond which it is judged to be unqualified. | Simple missing parts detection (e.g. missing food packaging, missing hardware) |

| Sorting Pusher/Flap | Push the non-conforming products from the belt to the waste channel, and the conforming products continue to be conveyed. | After receiving the unqualified signal from the detecting device, the pneumatic push plate will act (pushing the material horizontally) or the flip plate will turn over (the material will fall into the channel below) | Automated screening to avoid the flow of non-conforming products to the next process |

Four,Auxiliary Function Devices

In addition to the core functions, with auxiliary devices can solve the material temporary storage, manual collaboration, dust and moisture, etc., to adapt to more scenarios.

1,Tooling boards (pallets)

- Function:Conveyance of fragmented parts on a work plate of uniform specifications avoids collision and abrasion of parts, while facilitating positioning and gripping.

- Applicable Scenarios:Scratch-prone plastic parts, assemblies with multi-part combinations (e.g., cell phone cases/keys).

2,Manually operated platforms

- Function:A stand with an anti-slip table is set up next to the conveyor for workers to complete semi-automated operations such as manual assembly, labeling, and inspection (suitable for processes that cannot be fully automated for the time being).

- Features:The platform height can be adjusted (adapted to the worker's operating comfort), and some of them can be equipped with material boxes (for storing small parts).

3,Dust Cover / Guardrail

- Function:Dust cover (made of transparent acrylic) covers the top of the belt to prevent dust from falling into the precision parts (e.g. electronic assembly line); guardrails (metal mesh) are set on both sides of the conveyor to avoid personnel from accidentally touching the moving parts.

- Applicable Scenarios:Scenarios with high cleanliness requirements (e.g., medical device assembly), workshops with personnel movement.

4,积放机构

- Function:When the downstream work station is not completed for the time being, the accumulation mechanism (e.g., belt sectional speed control, blocking cylinder) allows the material to queue up on the conveyor to avoid congestion.

- Applicable Scenarios:Assembly lines with mismatched speeds at each station (e.g., fast front sequence, slow back sequence).

Five,Core Principles of Matching

Adaptability:The size, load capacity and speed of the unit need to be matched to the small belt conveyor.

Automation Synergy:All devices need to be linked via PLC (programmable logic controller) to avoid conflicting actions.

Scalability:Reserve interfaces (e.g. sensor mounting holes, robotic arm fixing position) to facilitate the later addition of processes

VI. Summary

By matching the aboveSmall Belt ConveyorIt can be upgraded from a single conveying tool to the core of an assembly line that integrates conveying, assembling, testing, and sorting, and is suitable for the small- or large-volume production needs of a number of industries, such as electronics, hardware, food, and medical devices.