在Automatic production line里,有个基础到容易被忽视却至关重要的角色——它负责把物料精准送到每个工位,让生产流程顺畅衔接,这就是Pallet conveying lineThe first thing you need to do is to use it. Many people may not notice, if it is missing, even the most advanced equipment will fall into the “no way out” of the dilemma. Today, we will briefly show and tellPallet conveying lineWhy it is so important and the role it plays in production.

One,Pallet conveyor lines: stabilizing the productivity of thebasic disk

在Automatic production lineIn the process of product processing, the stability of transportation directly affects the production efficiency and quality of finished products. The most common conveying methods of automated production line are horizontal linear conveying, horizontal circular conveying, up and down elevated conveying and climbing conveying methods. From the point of view of the conveying method, the stability of horizontal conveying far exceeds that of up and down lifting and slope climbing conveying, so it becomes the first choice of most enterprises.Pallet conveying lineIt is the “main force” of horizontal transportation.

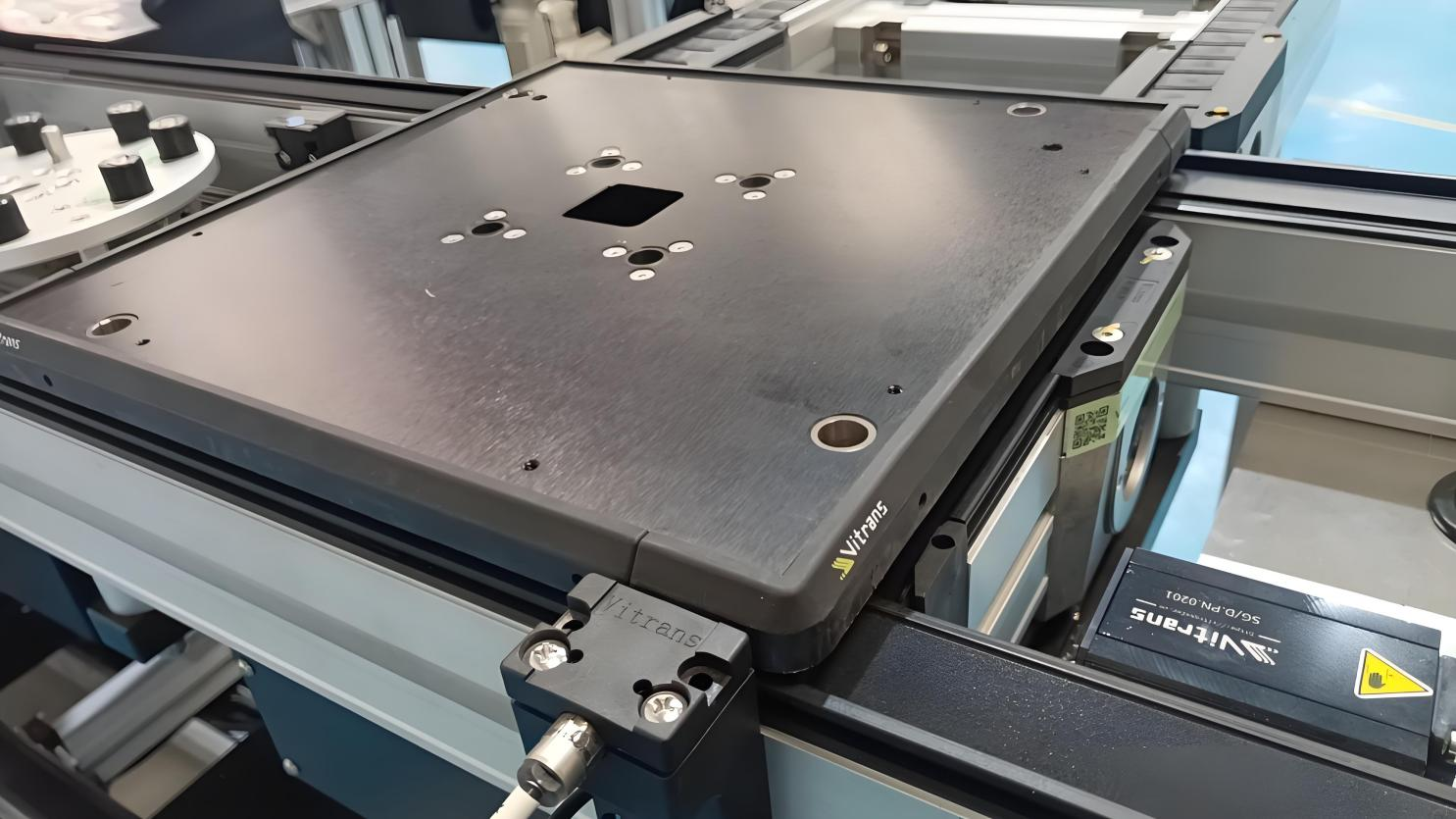

It allows the materialsuccessivein accordance withmeterMoving:After the pallet is loaded with parts to be processed, it is smoothly transported from one station to the next with the help of belts, chains and other media. When it reaches the station, the stopper precisely stops the pallet, the processing equipment completes the operation, while the conveying medium can continue to run, once the process is over, the pallet automatically goes to the next station. TheNo waiting, no laggingThe model completely avoids the delay and error of manual handling, makes the production beat more controllable, and greatly improves the overall efficiency.

Meanwhile.Pallet conveying lineIt can also be adapted to the needs of different production environments.for examplenew energyIt can meet the requirements of anti-static and dust-proof in industries with high environmental requirements, such as electronics and electrical appliances; in heavy-load scenarios such as the production of automotive parts, part of the conveyor line such as thedoubled speed chain和platen lineSingle-stage loads of up to 4,000 kilograms can securely support heavy-duty machining needs.

Two,灵活适配Production Line Layout

Each factory has a different workshop size and product process, and the pallet conveyor line of themodular designThe ability to combine a variety of programs according to the actual needs just solves the layout problem.

①Want linear conveyor, synchronous belt,Flat Belt Conveyor LineAvailable on demand and can be up to 30 meters long;

②Turns are required, and 90° and 180° turn units can be easily realized, and also keep the direction of the pallet unchanged;

(iii) If material transfer between multi-layer wire bodies is to be realized.synchronous belt、Screws, rodless cylindersThree kinds of lifting machine can be competent, the fastest lifting speed up to 500mm / s, to meet the requirements of different beats.

Moreover, the pallet size can be customized, from 160mm x 160mm to 800mm x 800mm, with different materials of carrier boards, which can be adapted to all kinds of products. This flexibility allows small workshops to efficiently utilize space and large factories to build complex production links.

Three,Wide range of applications: multi-industryThey're all using it.

Pallet conveying lineIts practicality makes it shine in many industries. In the field of new energy, it can prevent static electricity and smoothly transport battery components to ensure precision processing; in the production of automotive parts, heavy-duty conveying line can carry large parts, with jacking positioning unit, to realize accurate assembly; in the electronic and electrical industry, high cleanliness of the overhead chain conveying line can avoid dust affecting the quality of the product; even in the field of food processing, part of the conveying line in line with hygiene standards, can also help the material safe Even in the food processing field, some of the conveyor lines meet the hygiene standard, which can also help the material safe transmission.

In conclusion.Pallet conveying lineIt is not only an important role in material handling, but also the key to the efficient and stable operation of automated production lines. With it, enterprises can realize the double improvement of production efficiency and product quality in the fierce competition.