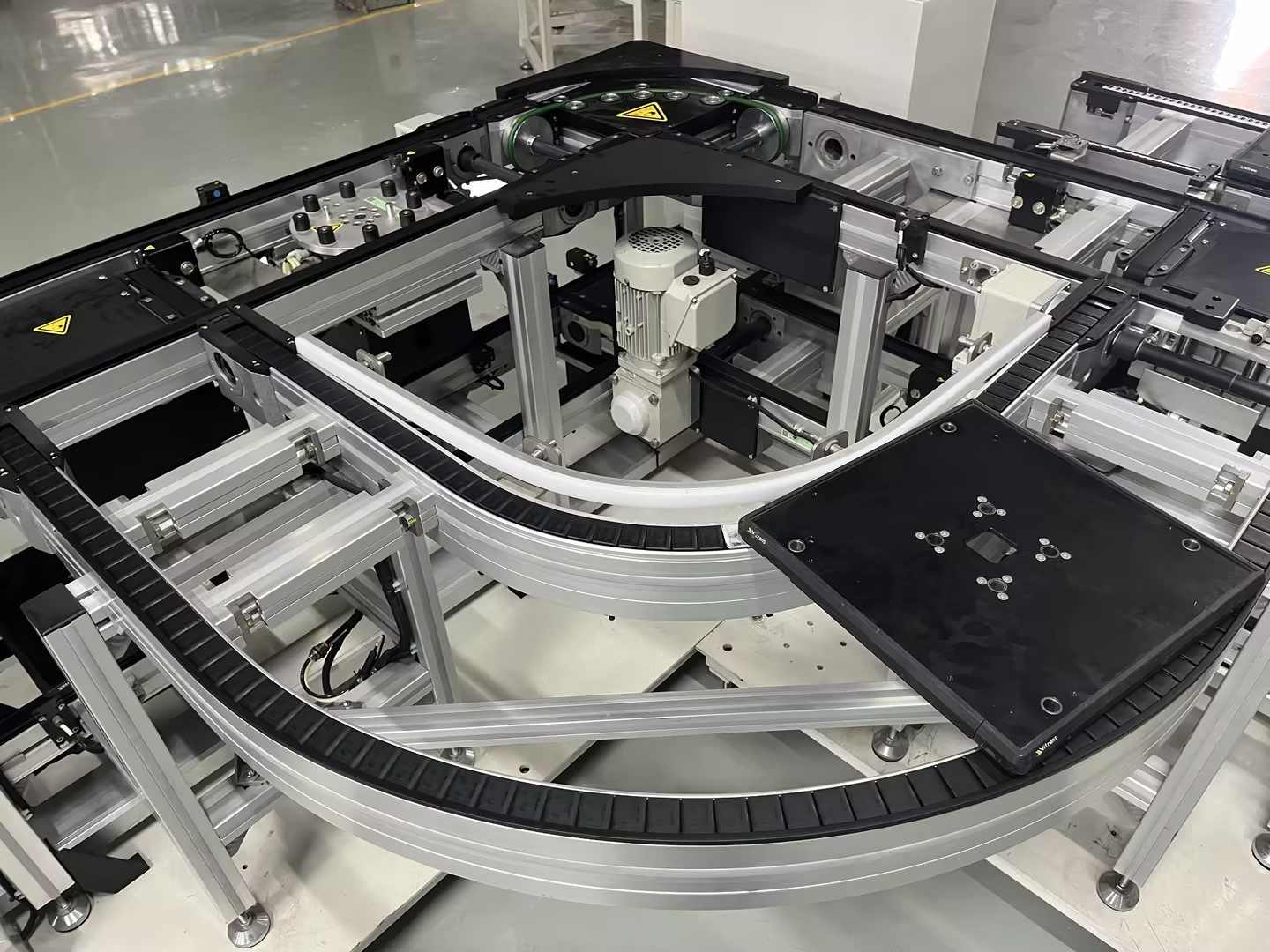

Modular Conveyor SystemsIt is a set of multifunctional conveying system based on standardized conveying line body, with modular mechanism that can be flexibly combined, and can be quickly set up and adjusted according to different production demands.Vitrans Wei Chuang的Pallet conveying systemsis typical.

One,principalspecificities

1,Standardization of core components

Conveying line body (such as BC2, FC2, AC2, etc. series), workpiece tray (WA2, WE2 two types) and supporting institutions (curves, lifts, etc.) have a unified standard specifications, such as the WA2 tray default adapted to theflat belt、toothed beltThe WE2 pallet is adapted by default to the transport mediumStacked roller chains, Top Chain.

2,Flexible combinations

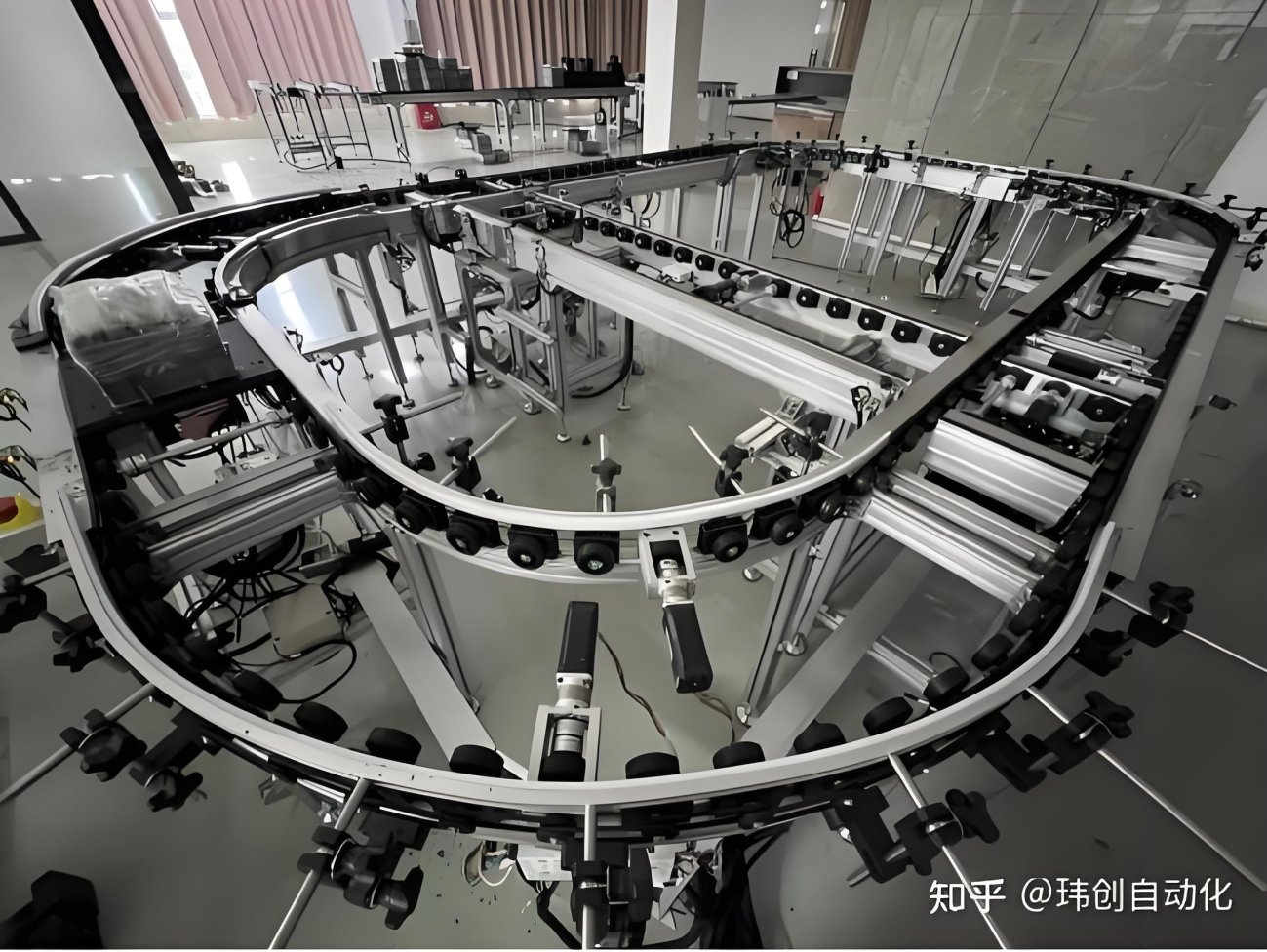

The layout can be adjusted according to the size of the site and the production conditions, such as horizontal circulation layout A/B, vertical circulation layout, and it can also realize multi-layer and multi-direction conveying through modules such as jacking traverse and elevator, for example, transferring pallets between multi-layer lines with LP/B synchronous belt elevator.

3,Controlled load and accuracy

Different components correspond to a clear load range, such as BC2 conveyor line with a maximum load of 60kg, AC2/H conveyor line with a maximum load of 2200kg; high positioning accuracy, PU jacking positioning unit repeatability of ±0.1mm, to meet the demand for precision machining.

4,environmental adaptation强

With an operating temperature range of +5 to +40°C and a relative humidity of 5% to 85% (non-condensing) and anti-static properties, some components (such as the AC2 conveyor line) can also be used in harsh environments with swarf and sand.

Two,categorization

1,By type of core component

①conveying line

- Light Duty:BC2/BC2/M series, the conveying medium is toothed belt, the maximum load is 60kg, suitable for short distance under 6 meters, clean environment light load conveying, such as electronic components conveying.

- Medium load type:FC2 series (flat belt, max. load 250kg), PC2 series (overhead chain, max. load 200kg), FC2 is suitable for long-distance conveying over 10 meters, PC2 is suitable for high-cleanliness light load scenario.

- Heavy Duty:AC2/AC2/H series, the conveying medium isStacked roller chains,AC2最大负载700kg,AC2/H最大负载2200kg,适用于Auto Partsand other heavy loads are conveyed.

②Workpiece pallets

- WA2 type:With PA (polyamide) wear pads, suitable for flat belts, toothed belts, etc. Maximum load 120 kg, 42 standard sizes, load plates can be customized.

- WE2 type:with PE (polyethylene) wear pads, suitable forStacked roller chains、top chainWith a maximum load of 240kg, it also supports the customization of load boards, and has embedded metal inductors at the bottom and sides to meet anti-static requirements.

③Matching Modular Mechanisms

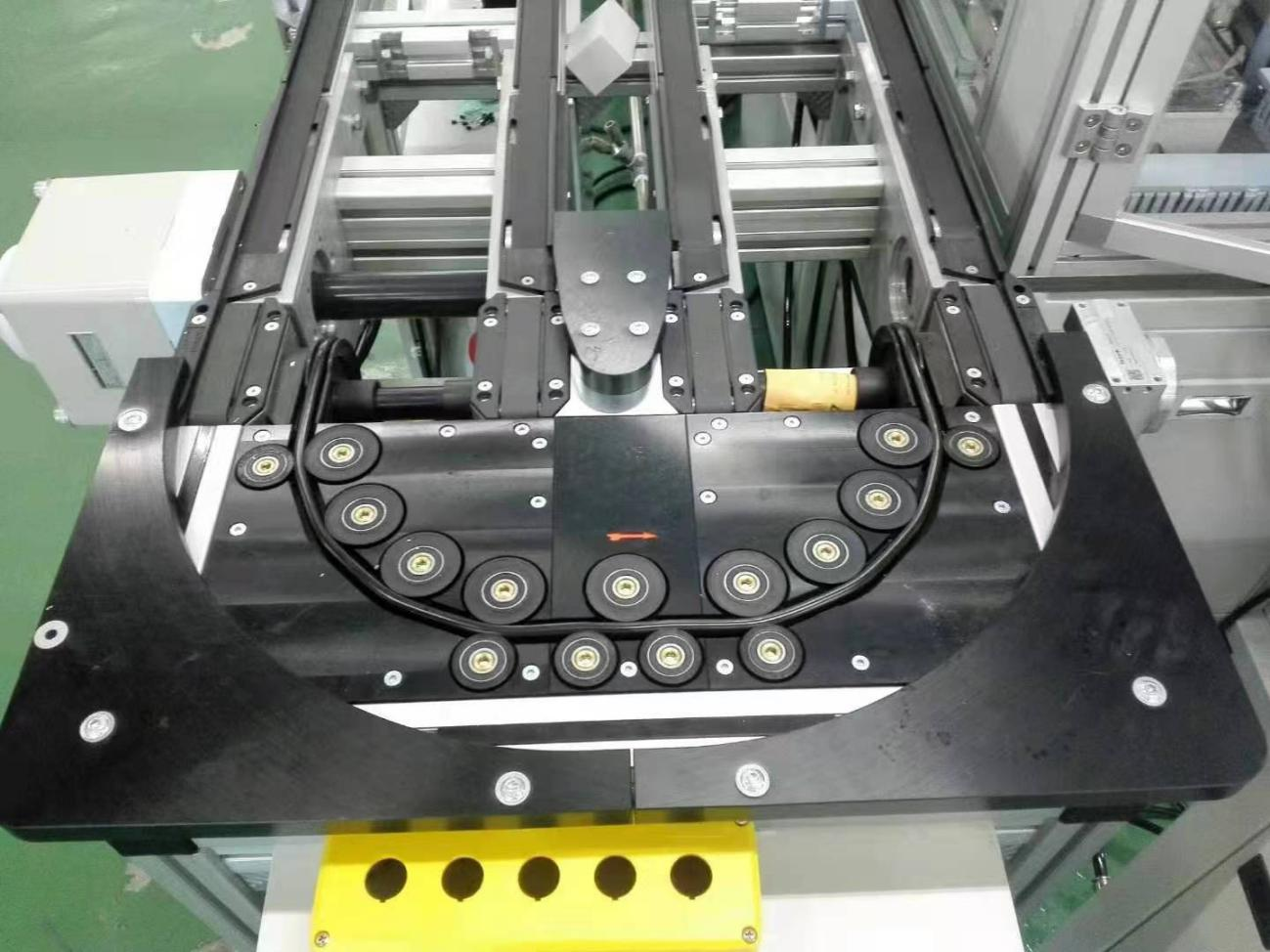

- Positioning Class:PN pallet guide plate (repeatability ±0.5mm, for coarse positioning), PX pin positioning (precise positioning of machining stations), PU jacking positioning unit (jacking height 2.5mm, simple positioning operation).

- Direction switching class:KV/90, KV/180 turning units (round belt drive, max. load 20kg), CV/90, CV/180 turning units (plastic flat-top chain drive, max. load 90kg for CV/90), PR jacking swivel unit (can be swiveled 90°/180°, max. load 30kg).

- Elevation class:LP/B synchronous belt elevator(fastest speed 500mm/s, for multi-layer wire body), LP/P rodless cylinder lifter (fastest speed 300mm/s, cost-effective choice for double-layer wire body), LP/SScrew jacks(Maximum speed 500mm/s, scenes with fast beat requirements).

- Control class:SG series stopper (pneumatic stopper, buffer stopper, etc., e.g., SG/D150 can stop pallets up to 150kg), ZJ/S (side), ZJ/U (bottom) switch bracket (fixing proximity switches, sensing the position of the pallet).

2,According to the layout

- Horizontal layout:Horizontal Circulation Layout A and Horizontal Circulation Layout B, suitable for flat sites, realize pallet circulation conveying through the combination of straight conveyor lines and curves.

- Vertical layout:Vertical circulation layout, utilizing elevators to connect multi-layer horizontal conveyor lines, saving floor space and suitable for scenarios with sufficient workshop height.

Three,Application of modular conveyor systemsmileage

1. Reduced planning and design costs:Predefined function modules reduce the customization design workload and eliminate the need to redesign the structure, saving time and labor costs.

2. Reduction in installation and commissioning cycles:Standardized component installation process is unified, high compatibility of each module during commissioning, no need for frequent adjustments.

3. Facilitate later maintenance and remodeling:Components can be replaced individually, eliminating the need to replace the conveyor line as a whole; if production needs change, it can be expanded to multi-layer conveying without having to rebuild the system.

4. Enhancement of productivity:Able to process according to theBeat OptimizationLayout to reduce artifact waiting time.

Image source:Wei Chuang Automation)

Four,commonly seenApplication Sectors

1. New energy industry: for battery cell and module transportation

2. Automotive parts industry: conveying engine parts, chassis components and other heavy-duty workpieces.

3. Electrical and electronic industry: conveying circuit boards, small electrical components

4. Motor industry: Conveying and positioning of motor cases, rotors and other components