In factory automation, the aspect of material movement is crucial. Among themPallet conveying lineIt seems to be the most basic, but it plays an indispensable role. It is not a simple conveyor belt, but relies on specificWorking PrincipleThe key equipment for efficient material handling and smoother production. The following is a combination ofPallet conveying line的工作原理,从不同的Application Cases场景展开分析——输送线到底怎么助力工厂自动化完成高效生产的。

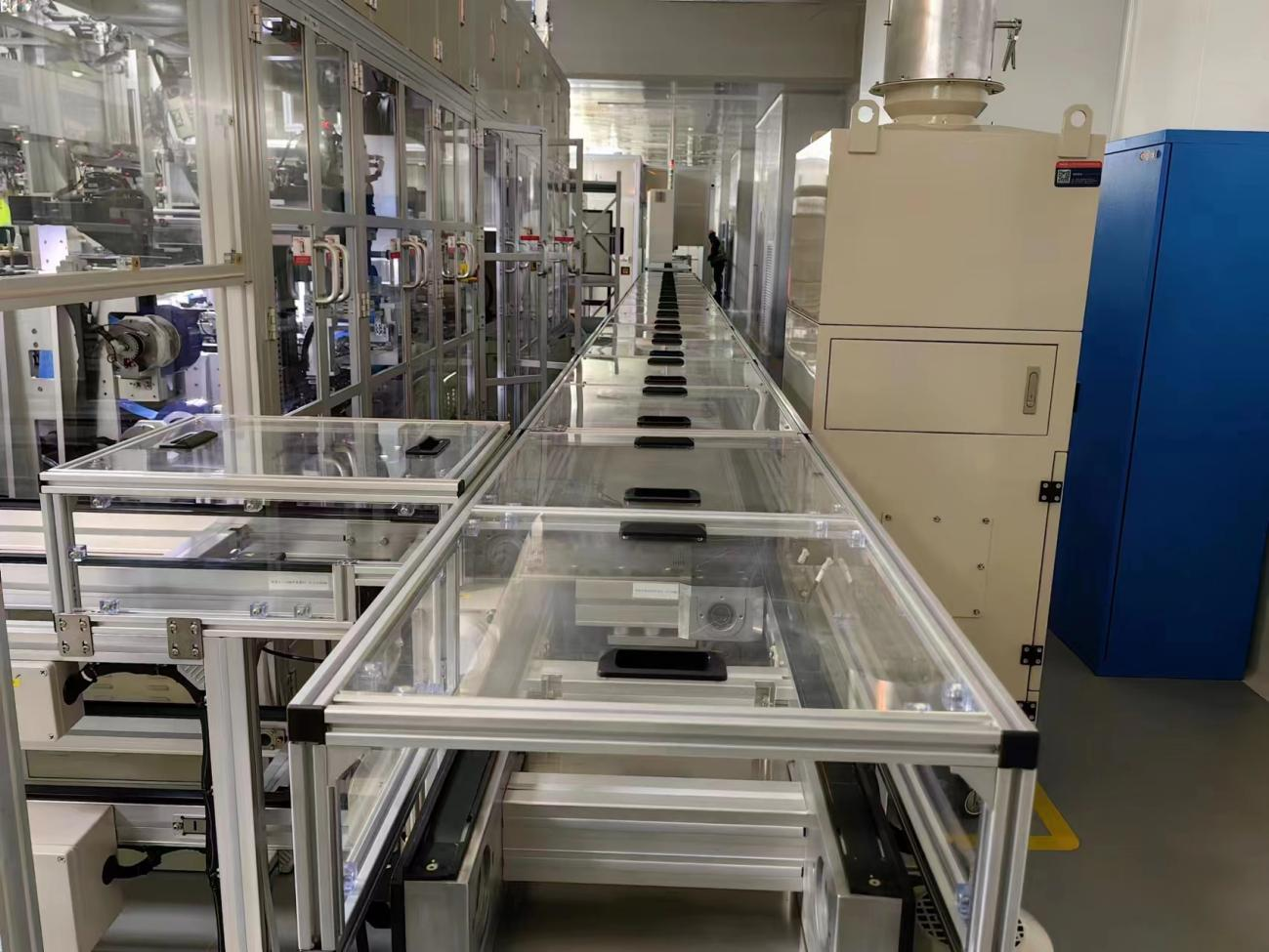

01New Energy and Energy Storage

Pallet conveying line的Working Principle: Through the power device (such as motor) to drive the transmission parts (such as chains, belts), so that the pallet or work plate carrying the material to move in accordance with the set path.

在新能源电池电芯和电池装配中,就是靠这种精准驱动,实现全自动化运行,达到单线24PPM、5PPM的生产效率,modular design还能灵活调整传动路径。

在Energy Storage Battery PACK Testing和Battery module assembly testThe conveyor line not only relies on motor-driven chains to carry 450KG and 300KG pallets, but is also equipped with a jacking device - a lifting mechanism driven by pneumatic cylinders or motors - to accurately position the pallets for subsequent testing and assembly, which is perfectly suited to meet the high requirements of precision and load in this type of field.

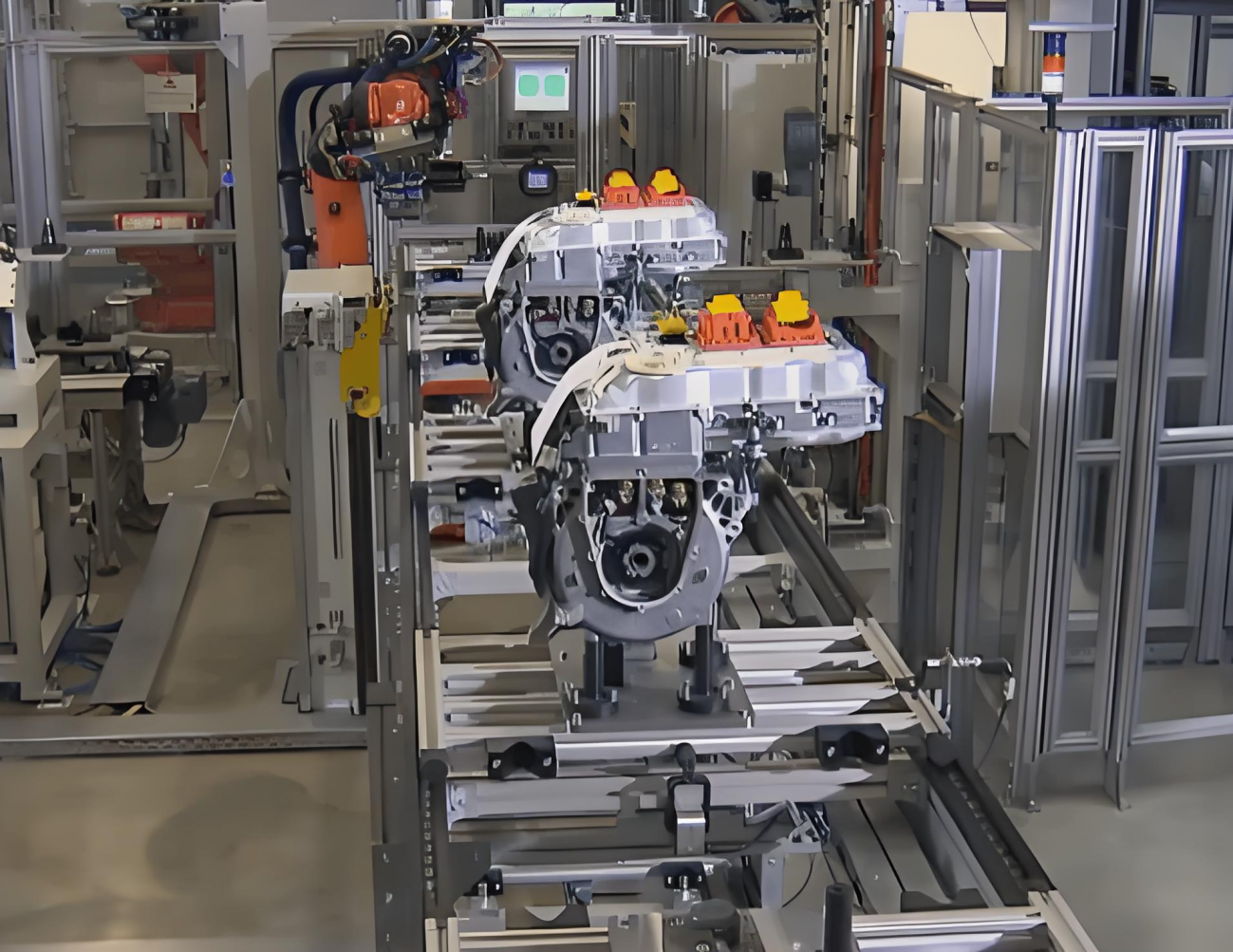

02Automobile-related production

With the variety of automotive production scenarios, the conveyor line will choose different transmission methods according to different needs.

①Motor assembly line:Adopting U-shape layout, it relies on belt or chain drive to let the material move along the U-shape path, and the 40-meter long line body can also save space;

②car stereoassemble and install线:Adopting the upper and lower return mode, it is through the upper and lower drive parts running in reverse, together with the U-shape layout, so that the material can circulate among dozens of automatic workstations and handmade stations, and stably maintain a high speed production beat;

③Automobile parts assembly line:In the face of high temperature environment, such as 150 ℃ high temperature furnace, the conveyor line can choose high temperature resistant material.doubled speed chainTransmission - Chain link engages with the pallet, precisely controlling the movement speed to ensure that the material is in the furnace for 20 minutes to keep warm requirements.

03Home Appliances and Robotics Manufacturing

在Appliance and robotics manufacturingIn this case, the conveyor line is adapted to the requirements by combining different drive modes.

①Hair dryer and vacuum cleaner assembly line:靠synchronous belt和flat beltTransmission - The belt surface is flat, suitable for smooth movement of lightweight materials, and the circular belt line also allows the materials to circulate, realizing semi-automatic assembly; 46m to 90m line length, with 34 and 21 stations, to meet the mass production.

② Service robot production line:With 08Bdoubled speed chainTransmission - through the chain speed increasing mechanism, let the pallet adjust the speed according to different workstation needs, 10 sections of the line body to cover the whole process, 90KG load capacity by high-strength chain to achieve; server assembly line is a combination of belt line and roller chain drive, the belt is suitable for lightweight parts, roller chain to carry heavier materials, easy to adapt to the production of 6 types of products.